Waterproofing a bathroom under tiles: which is better?

INa lag destroys the structural frame of a building made of reinforced concrete within half a century, steel structures in 10 - 15 years, wooden frames of walls, floor beams in 5 years maximum. Therefore, the supporting structures are protected by pasting, coating or plastering materials or impregnated with penetrating compounds. Each property owner is interested in waterproofing a bathroom under a tile, what is better to choose and which technologies are cheaper.

The content of the article

Video: DIY waterproofing under the tiles

Types of waterproofing

Advertising of manufacturers of waterproofing and vapor barrier materials cannot serve as a guide for finishing interiorsas it is designed to increase sales. The joint venture regulations contain recommendations for waterproofing foundations. Therefore, the home master needs to know the nuances:

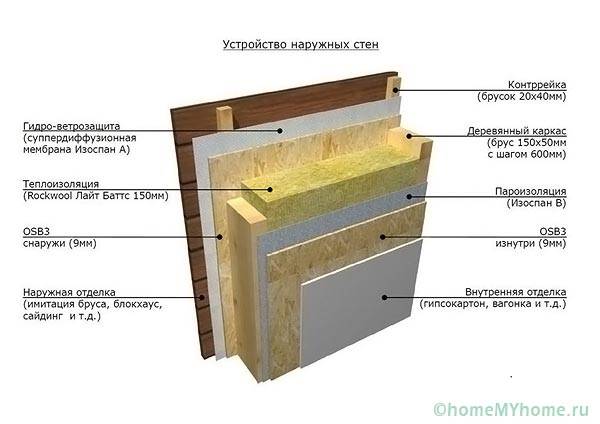

- vapor barrier film, the membrane does not allow water or wet steam to pass through, it is mounted inside the rooms under the cladding;

- despite the high characteristics, vapor barrier materials cannot provide 100% impermeability, part of the moisture still penetrates into walls, ceilings;

- therefore, waterproofing is mounted outside, through which steam freely passes from the inside, but water cannot penetrate from the outside.

All this is true only for the external structures of the building - the roof, foundation and external walls. Ceilings and internal walls cannot be protected with vapor barrier material:

- if you put the membrane on one side, moist air will penetrate the wall from the adjacent room;

- if you cover the wall with films on both sides, 10 - 30% of moisture will still penetrate inside, it will not be able to evaporate outside, the supporting structure will collapse even faster.

Useful advice! Walls, floors, ceilings of rooms with high humidity (bathroom, bathroom, toilet) can be protected mainly with waterproofing materials.

Vapor barriers are produced in the form of films, membranes, on which it is impossible to stick tiles on the walls. Waterproofing coating, penetrating, plaster mixes have high adhesion to tile adhesive. The floors can be covered with vapor barrier films and waterproofing roll materials.

Thus, the question of waterproofing bathroom under tiles which is better, a partial answer was obtained on the types of materials. It remains to study the application technologies, the repair budget, the availability for independent work.

Description, pros / cons of each technology

Waterproofing a bathroom under tiles which is better? There are several important points to keep in mind when answering this question:

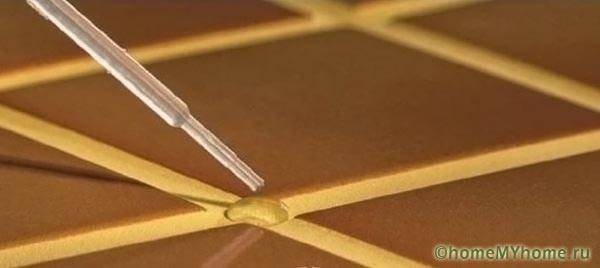

- the tile itself does not allow water to pass through, numerous seams are a weak point, if you add a penetrating additive to the glue or treat the grout with a special varnish, the floor / wall coverings become 70 - 80% waterproof;

- water flows down to the floor under its own weight, so the protection in the lower level should be more serious than on the walls;

- wooden floors along the logs are faced with porcelain stoneware, tiles are extremely rare, usually reinforced concrete slabs are finished in this way.

All existing technologies for the manufacture of hydro-barriers are used depending on the preferences of the owners, the structure of the ceiling, the walls.

Related article:

Basement waterproofing from the inside from groundwater. Why are groundwater dangerous? How to protect the basement from their impact? Answers in a special publication of our portal.

Coating waterproofing

When waterproofing the walls of the bathroom under the tiles is chosen, which is better, the coating compounds are usually in the lead:

- bituminous mastics - maximum resource, high price;

- polymer mastics - environmental friendliness, simple application, budget option;

- epoxy mastics - not recommended for residential buildings.

There are one, two component hot and cold (ready to use) mastics. Polymers, rubber, rubber crumb, modifiers are added to bituminous compositions. This improves the elasticity and strength of the layer.

Due to the fact that the films formed after the evaporation of the solvent or as a result of a chemical reaction are covered with a layer of glue, facing, atomosphere resistance, UV resistance, other characteristics are not of particular importance. Unlike the foundation hydro-barrier, there are no mechanical loads, material weathering in the ventilated space of the roof.

Helpful information! Sprayed liquid rubber is a common bitumen mastic with the addition of crumb rubber. When ordering a service, the owner significantly overpays for the use of special equipment. Although, it may well buy the same material, apply it with a brush / roller yourself.

The nuances of the coating waterproofing technology are:

- two-component formulations have a short shelf life after mixing, so they should be diluted in small portions;

- hot mastics require additional equipment, are more suitable for foundations.

When buying mastics, consider:

- budget options cost around 35 rubles / kg, they do not meet the requirements of GOST, since they contain building bitumen and tar;

- the solvent of standard mastics is the naphtha fraction, which has a pungent odor, they cost around 90 rubles / kg, contain BN 50/50 or BN 70/30 bitumen;

- The premium class costs about 150 rubles / kg, contains bitumen BN 70/30 or BN 90/10 modified with rubber crumbs.

Low-cost tar mastics flow down from vertical surfaces, harden within 5 days, and dramatically reduce the productivity of repairs. Depending on the content of additives, mastics have the following characteristics:

- rubber - elongation 400%, consumption 1.7 kg / m2, water saturation 0.2%, no need to heat;

- rubber - elongation 200%, water absorption 2%, consumption 0.7 kg / m2drying 5 - 7 hours;

- latex - used for outdoor work, as it is expensive, not afraid of frost, heat;

- polymer - protects against radon, dries 6 - 8 hours, is cheap.

Walls and floors are coated with mastics only after primer treatment. This primer can be made from mastic by thinning or purchased separately.

Oleechnaya waterproofing

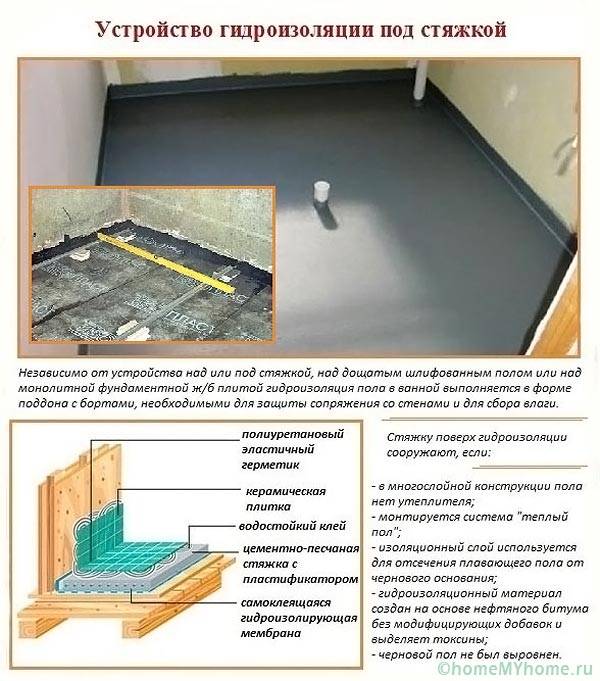

To reduce repair estimates usually used window waterproofing of the bathroom floor under the tiles. For this, various modifications of roofing material or polymer films are used.

Depending on the basis of the roofing material, the resource of the hydro-barrier will be different:

- cardboard - the minimum operational period, it is better not to use;

- glass canvas - the ideal balance between the repair budget and the durability of the hydro-barrier;

- fiberglass - hydroglass is more expensive, but operating costs are reduced;

In order not to buy / rent gas burners, propane cylinders for fusing conventional roll materials, you can choose modifications with a self-adhesive bottom layer. Pre-treatment of surfaces with primers is a must. Usually Technonikol, Bikrost, hydrostekloizol from different manufacturers are used.

Heavy PVDF membranes for bathrooms are too expensive, they are used for artificial reservoirs and the organization of drainage in baths.

Plastering compounds

To impart waterproof properties to plaster mortars, the following modifiers are added to dry mixes:

- liquid glass;

- sodium aluminate;

- ceresite.

The mixture should be mixed in small quantities, worked out for 20 - 40 minutes. There are gypsum-based, cement-based waterproofing plasters with the addition of polymer granules that increase the life of the mortar.

In contrast to classic plaster, mortars are applied in two stages (spraying + primer) without leveling. Therefore, the glue solution for tiles increases, but the materials have high adhesion to each other. The technology requires special skills, it is used less often than coating, pasting.

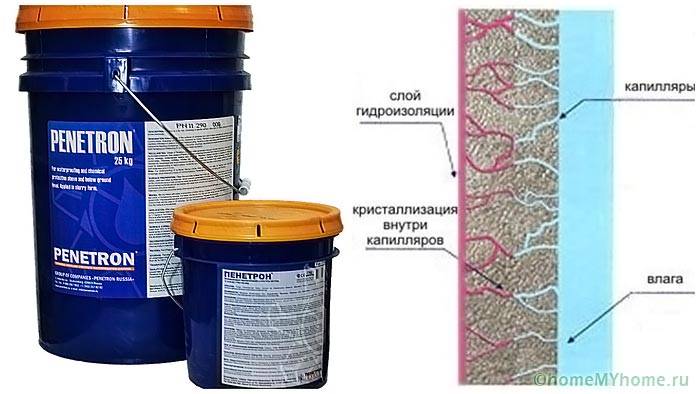

Penetrating waterproofing

The most reliable is the waterproofing of the bathroom floor under the tiles with penetrating compounds.

The application technology is similar to the coating method, however, after application, the Penetron components react with the cement stone, completely changing the structure of the structural material practically to the entire depth of the walls / floors.

In this case, pre-treatment of primers is not necessary, any chipped piece of concrete will retain the obtained properties until complete destruction. The leading manufacturer of materials in this group is Penetron, but the cost increases the repair estimate at least twice. Mixture consumption is within 1kg / m2, the resource is almost eternal, concrete dries up in 3 - 5 hours.

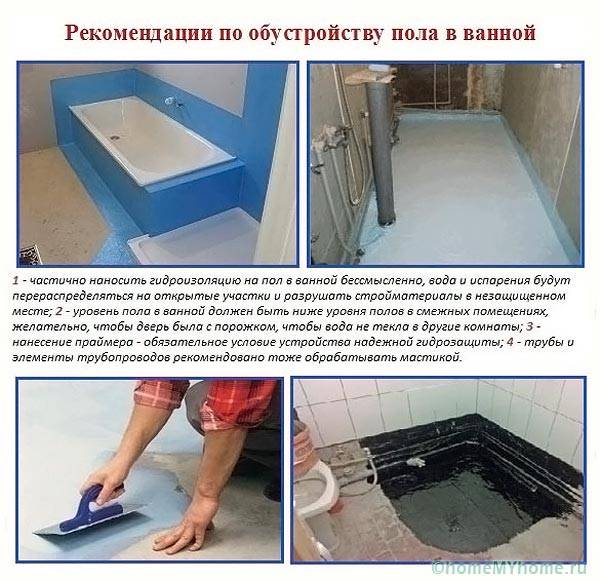

Tips, recommendations

After getting acquainted with the characteristics of the materials used as a hydro-barrier in the bathrooms, the home craftsman inevitably has additional questions.Therefore, the recommendations of experts will help you choose the optimal balance between the repair budget, quality, and service life:

- with a sufficient budget, it is better to treat all surfaces with penetrating compounds and forget about repairs, periodic restoration of the waterproofing layer - the concrete becomes waterproof to the full depth, the tile can be renewed even annually without any consequences;

- a budget option is fusing roll materials onto a screed with a start of 5 cm on the walls;

- even walls are easier to coat with mastics in order to hide defects in the flatness of the walls, it is better to use waterproofing plaster;

Conclusion

Thus, a home craftsman can pick up waterproofing materials and apply them to walls and floors before decorating supporting structures with porcelain stoneware / tiles on their own.

Video: bathroom waterproofing