Competent insulation of a wooden house outside: do it yourself

Thermal insulation of houses is carried out not only to reduce heating costs and reduce heat loss. High-quality insulation of a wooden house from the outside allows you to keep a comfortable coolness in the premises in the heat. This reduces the need for air conditioners and, accordingly, electricity consumption. It has been proven that external thermal insulation is much more effective than internal one.

The content of the article

We decide how and what to insulate a wooden house

Thermal insulation of a wooden structure can be done in two ways:

- create a screen that can protect from the wind;

- use an additional layer of insulation.

The use of the first option can significantly reduce costs during the heating period. For this, lining is often used, the combination of the elements of which creates an integral canvas. But such material is prone to cracking and deformation. In addition, it is difficult to install, and also has a rather high cost.

The most common options for thermal insulation of a house, which protects from cold and bad weather, is siding, equipped with an additional basis for insulation. The effectiveness of the material will increase significantly if a layer of insulation is placed under it.

Review of quality home insulation: how to choose the right insulation

Modern manufacturers offer a huge selection of all kinds of materials that allow you to insulate external walls:

- loose insulation;

- fiberglass wool;

- basalt wool;

- foamy polymers such as expanded polystyrene, penoizol, polystyrene.

Related article:

Floor insulation in a wooden house from below: technology and choice of material. In the article, we will consider what materials are for thermal insulation, which one is better to choose, the principle of installation work.

Loose heat insulators for insulating a wooden house outside

They are environmentally friendly, since they are not able to emit toxic substances during operation and are made from natural materials:

- vermiculite - formed during the processing of rocks, has the form of porous granules with air spaces;

- expanded clay - fired clay with a different grain fraction;

- perlite crushed stone - porous granules of volcanic glass, with a density of up to 100 kg per cubic meter.

The characteristics of these materials for external insulation of wooden houses can be found in the table below.

Table 1. Characteristics of materials for thermal insulation of wooden houses

As you can see, the thermal conductivity of bulk heat insulators is practically the same, the difference between them is only in price. All of them have excellent steam conductivity, which contributes to the free exit of moisture from the walls. In addition to steam conductivity and high environmental friendliness, these materials have the following qualities:

- resistance to high temperatures reaching 1100 degrees;

- the durability of materials is equal to the life of the building itself;

- not attractive to rodents;

- resistant to moisture;

- do not cake from time to time.

The disadvantage of bulk materials is poor thermal conductivity, which provides for the insulation of houses in regions with a warm climate.

Mineral wool

The material is the result of processing waste from metallurgy or rocks, such as dolomite or basalt. It differs in:

- environmental friendliness;

- durability of operation;

- incombustibility;

- high strength;

- sound absorption;

- elasticity;

- ease of installation;

- affordability.

For thermal insulation, roll material or basalt slabs are used. Such insulation is ideal for brick, gas and foam concrete, as well as wooden buildings.

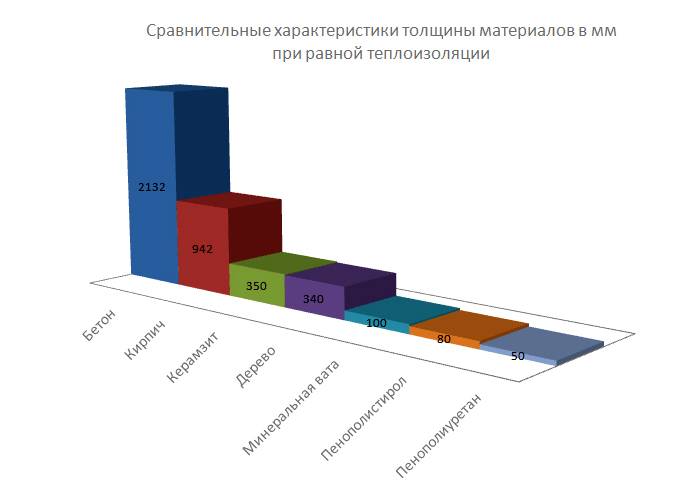

You can work with the material at any temperature, which is very convenient for insulating external walls. The most common application is to insulate wooden houses outside with mineral wool for siding.

Note! Practice shows that finishing joints with mineral wool is capable of provoking the formation of condensation due to the circulation of warm air.

Styrofoam (expanded polystyrene)

Refers to modern polymer insulation, and is widely used in construction. This material is characterized by:

- low thermal conductivity, amounting to no more than 0.051 W per m2;

- weak water absorption;

- high windproof and soundproof performance;

- durability, its operational period is more than 50 years;

- environmental friendliness.

It is also worth noting the low weight of the material, which reduces transport costs and installation costs. Thanks to this quality, the walls are not stressed, which eliminates the need to strengthen the foundation.

Another advantage of the material is its low cost, which allows external walls to be insulated. In this video, one person does the insulation of the house outside with foam plastic with his own hands due to the lightness of the material:

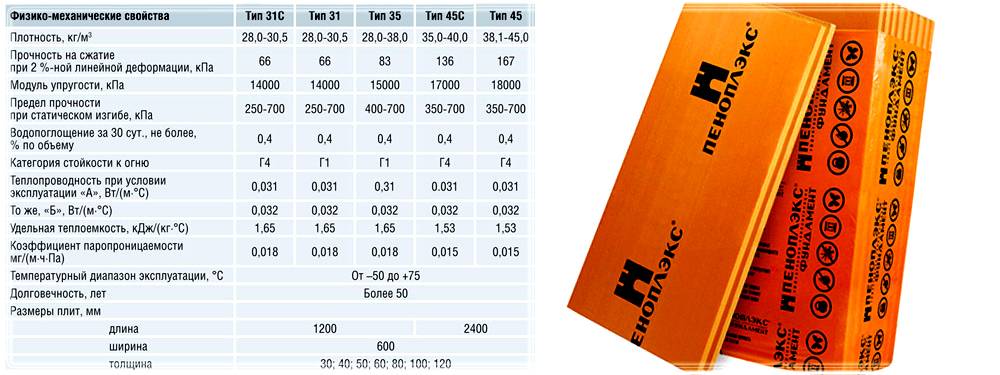

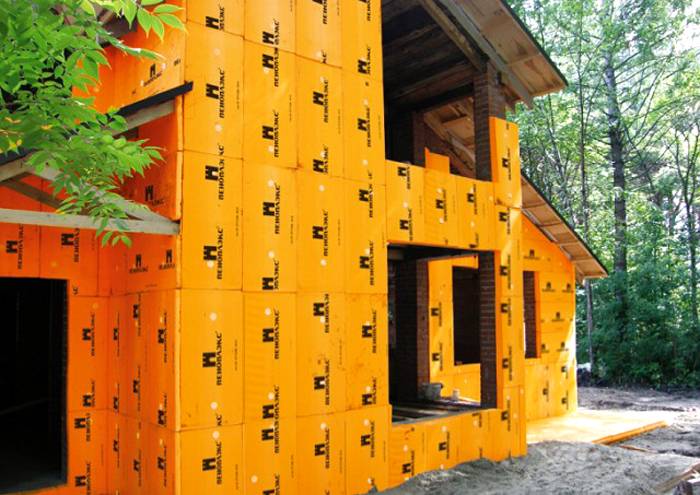

Extruded polystyrene foam

An innovative heat-insulating material, in the manufacture of which nano-particles of graphite are used, which contribute to an increase in energy saving and product strength. The thermal conductivity of polystyrene foam is 0.029-0.032 W per each m2.

In addition, the material is resistant to chemicals and mold, has high sound insulation and is not afraid of rodents. These qualities make it possible to use penoplex for external insulation of a wooden house.

Note! When insulating wooden houses with siding, they provide for the use of a material with air permeability. This excludes additional protection of the seal from moisture.

Related article:

Penoplex: technical characteristics. Having picked up slabs of suitable thickness, you can ensure a sufficient level of thermal insulation of the walls, floor, ceiling. Let's talk about this insulation in more detail in our review.

Polyurethane foam

The material has a cellular foam structure filled with air. This significantly reduces the coefficient of thermal conductivity, which is a maximum of 0.042 W per m2.

Due to the high adhesion of the material to any surfaces, an airtight coating is formed, which guarantees excellent hydro and vapor barrier. High elasticity, combined with seamless technology, make it indispensable for insulating frame walls and blown thermal insulation, as well as for complex configurations. The insulation is applied at any temperature, and the durability reaches 30 years.

The disadvantages include the too high cost of polyurethane foam, as well as the need to use special equipment.

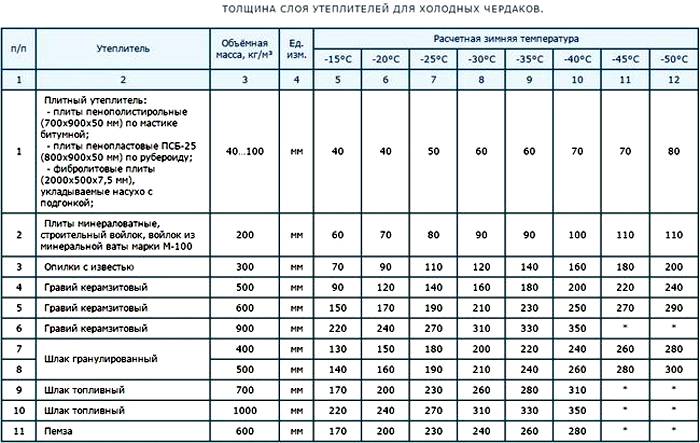

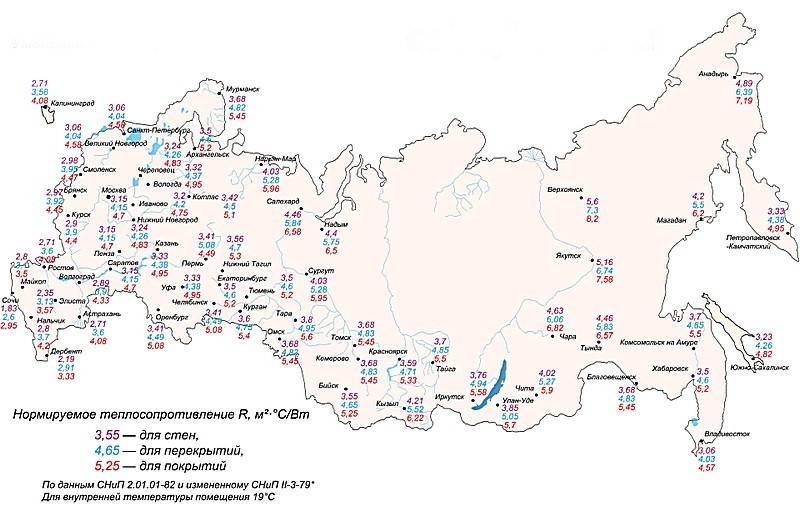

We calculate the thickness of the insulation

In order for the insulation of a wooden house from the outside to be effective, it is necessary not only to choose a heat-insulating material, but also to correctly calculate the required thickness, which will depend on the ability to resist heat.

This is the opposite indicator of thermal conductivity, the coefficient of which is indicated by the manufacturer on the packages. To calculate the coefficient of resistance to heat transfer, there is a formula:

R = d / k, Where

d - corresponds to the thickness of the material, and k - its thermal conductivity. The higher the value obtained, the higher the thermal insulation efficiency will be.

Insulation allows you to reduce the loss of heat energy through floors, walls, roofs. The lack of thickness of the insulation can lead to a displacement of the dew point inside the room, which leads to the formation of condensation, provoking the appearance of fungi, as well as dampness. Too large a layer of material is not capable of leading to significant temperature changes, however, it forces significant financial costs, which is irrational. To save money by providing optimal conditions, it is necessary to correctly calculate the thickness of the insulation.

Useful advice! In addition to wall insulation, it is possible to insulate the foundation, which will prevent the basement from freezing.

Calculator for calculating the thickness of the insulation of the walls of a wooden house

Related article:

Insulation for the floor in a wooden house, which one is better and how to choose? The article deals with the requirements that apply to insulation, an overview of producers and the average prices, a step by step process of warming the floor.

Conclusion

Decide what is better insulate the wall outside the house, you should own. However, when choosing insulating materials, you should definitely take into account the following factors:

- material resistance to moisture, since the facade exposed to atmospheric agents;

- combustibility - to choose a material containing flame retardants that prevents the spread of fire;

- ease of installation is an important quality that allows you to do the work yourself;

- high vapor permeability;

- the degree of specific heat;

- price index also does not have the latter value.

All materials have different features, that does not give a clear answer, which one is better. The choice will depend on the characteristics of the building, as well as the quality and wall thickness. Each of these heaters has a right to exist and is able to effect with proper application.

Video: wooden house - the sheathing, and how warm