Floor insulation in a wooden house from below: technology and choice of material

If, during the operation of a residential wooden house, residents feel that the floor remains cold at any time of the year and no heating can save them from this phenomenon, then there are design errors or construction defects. A poorly insulated floor creates problems for residents, as the energy consumption for heating increases significantly. Insulation of the floor in a wooden house from below should be done immediately after these unpleasant symptoms are detected.

The content of the article

Video: how to insulate a wooden floor from the bottom of the basement

Insulation materials

Thermal insulation is achieved when a layer of dry air forms between the cold zone and the warm one. In building structures, this effect can be obtained using porous materials. They can be bulk, slab, roll, or produced in the form of foam, which polymerizes in air. For insulation after completion of construction work, any of them are suitable.

Mineral wool

Mineral wool includes the following materials, which differ slightly in degree of thermal conductivity, but in terms of installation technology, applications and physical properties are very similar:

- glass wool

- mineral wool (basalt or made from other volcanic rocks);

- slag wool.

All these materials have an important quality - they are not flammable, destructive changes begin only when exposed to temperatures of 700 degrees and above, while the insulation does not ignite at all. It comes in hard slabs or soft rolls that are easy to cut and stack. When working with this insulation a respirator is required as particles must not enter the lungs. For private houses, mineral wool is also good because rodents and harmful insects do not start in them.

Expanded clay

The traditional material for insulating floors and ceilings is expanded clay. It is absolutely safe, environmentally friendly and fireproof.Moreover, its thermal insulation qualities and low price are the main selection criteria. The only inconvenience is the release form. Since expanded clay is a bulk material, it is necessary to prepare special cells for its laying and arrange high-quality waterproofing.

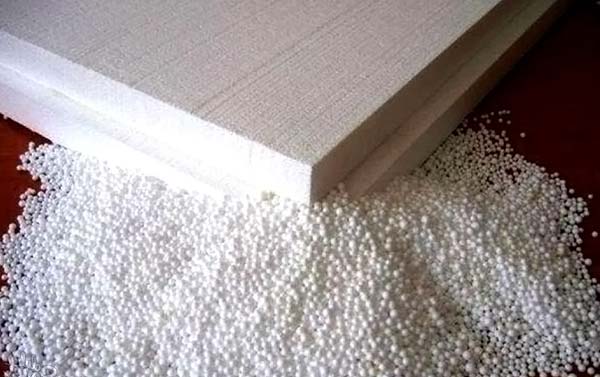

Styrofoam

Warming the floor in a wooden house with foam from below is considered one of the easiest ways to provide additional thermal insulation. Foam plates are very cheap, and their thermal insulation properties are an order of magnitude higher than that of mineral wool and expanded clay. However, such insulation is not safe for wooden houses - when exposed to an open flame, it instantly ignites, emitting corrosive smoke. In addition, rodents often nest in its thickness, which will be impossible to get rid of.

Ecowool

Ecowool is a cellulose-based material. It is produced from waste paper by adding borax and boric acid. When in contact with wood, such insulation will play the role of an antiseptic, in addition, a mixture of 80% cellulose, 12% boric acid and 8% borax is non-combustible, which is important for wooden buildings. Ecowool is used in the form of bulk material, having previously loosened it in an auxiliary container. Waterproofing is needed only from the bottom, and the vapors coming from the room can be retained by a thin top layer of insulation without losing its insulating properties.

Vermiculite

Vermiculite is a mineral insulating material that, in addition to construction, is used in the agro-industrial sector. It is produced without any chemical additives, is a completely natural material, does not burn or melt. Its only drawback is the ability to actively absorb moisture and lose its insulating properties, so its use requires a high-quality waterproofing device.

Related article:

Insulation for the floor in a wooden house. What is the best material for floor insulation? How much do they cost and which company to choose? More details in a separate publication.

Installation principles

Thermal insulation of floors in wooden houses from below implies complete dismantling of the existing floor. The finishing coating is carefully dismantled, the floorboards and other layers are removed. The preparation process also implies a thorough examination and identification of the cause of heat loss. They can be caused not only by the lack of insulation, but also by the ineffective operation of the existing insulation layer. Most likely, this is caused by poor-quality waterproofing or insufficient insulation thickness.

After dismantling the boards, you must completely remove the thermal insulation, if necessary, dry it thoroughly for reuse. The waterproofing layer is also removed, and its condition is analyzed. Installation of a new insulating layer can be started only when only logs remain in their place from the entire structure, while the rest of the elements are removed.

Thermal insulation of a wooden floor from below in a private house is performed in the following order:

- Rotten logs are checked and, if necessary, replaced;

- Attached to the lags from below plywood or any board, that is, a raised floor is formed, the only task of which is to serve as the basis for the insulation;

- Waterproofing is laid - a dense plastic film;

- The selected thermal insulation is laid;

- Boards are laid and the topcoat is restored.

What material to give preference

In terms of efficiency, the main types of insulation do not differ significantly from each other.Insulation materials are best suited for use in wooden houses, which first of all meet safety requirements, that is, they do not burn and do not emit harmful substances. In second place in terms of importance is hygiene, that is, the ability to resist the occurrence of mold, insect colonies or rodent families, since in a private house, you can get a lot of trouble from such intruders. The third selection criterion is ease of installation and cost.

Summing up

So why is it still necessary to remodel floors in a finished home?

- a cold floor is a guarantee of frequent colds among residents of the house;

- economic damage from uncontrolled heat loss can amount to tens of thousands of rubles in one winter season, especially when using electric energy as the main one;

- poor thermal insulation is almost always accompanied by high humidity, which significantly reduces the life of the load-bearing timber elements.

Video: floor insulation in a wooden house