Siding "under brick" and "stone" - varieties, characteristics, installation features

Houses built from natural stone or bricks, have always been considered more solid, durable and prestigious than buildings from cinder blocks, wood or sandwich panels... Naturally, the cost of material and work for the construction and decoration of a brick or stone house is very high. In addition, one should take into account the increase in time spent on the construction of such a capital structure, the need to create more durable and expensive foundation, the need for additional insulation and other factors. An alternative to this construction method is the use of brick and stone siding.

The content of the article

Varieties of siding "brick" and "stone"

Siding "brick" and "stone" is made of various materials with different performance characteristics. At the same time, the similarity of the imitation of the texture and color of the product depends solely on the quality of the product and the technologies used by the manufacturer. Siding "brick" and "stone" can be made of the following materials:

- polymers;

- metal;

- fiber-reinforced concrete;

- polymer siding.

Polymeric

Presented by materials of two types: vinyl and acrylic:

- Vinyl siding (PVC - polyvinyl chloride) it is highly resistant to biological corrosion. It is not susceptible to decay, fungus or woodworm beetles, mold, etc. However, vinyl siding can be damaged by rodents. PVC has a relatively high resistance to impact deformation.Siding from good manufacturers fade poorly in the sun and retains its original appearance during the first 5-10 years of operation. At the same time, most manufacturers regulate the service life of vinyl siding for 30-50 years. Thanks to special additives, vinyl can withstand a fairly wide range of operating temperatures -50 ° C ... + 50 ° C. When installing vinyl siding, the high coefficient of linear expansion of PVC must be taken into account. If miscalculations are allowed when arranging damping gaps between the elements, then with a sharp or smoother but prolonged temperature change (daily and annual fluctuations), the lining material can swell at the joints.

Important! A common, rather serious disadvantage of polymer siding "like a stone" and "brick" is its fragility at low temperatures.

- Acrylic siding. Most of the performance characteristics are similar to vinyl. Differs in increased strength, resistance to temperature changes and various chemicals in comparison with PVC products. The cost of acrylic cladding is 5-15% higher than vinyl.

Metal

Metal siding is usually made of galvanized steel, rarely aluminum. It has an external protective and decorative polymer film coating. Differs in high strength and resistance to external mechanical stress. Expensive products from leading manufacturers quite accurately repeat the external shape and surface structure of natural materials or bricks. The budget options have no relief, and the texture on them is imitated by an external pattern. The material is not subject to thermal deformation, is relatively lightweight and does not require reinforced lathing. It is implemented in the form of long elements. Needs trimming during installation. In this case, you should pay attention to the protection of the cut points from corrosion.

Important! Most craftsmen use an angle grinder (grinder) when trimming metal siding. This is absolutely impossible to do. When heated, part of the protective polymer coating peels off, which will lead to corrosion during further operation.

Fiber cement

Fiber cement consists of high quality cement, fine sand and microfiber as a reinforcing material. In terms of its technical characteristics, it most closely resembles natural stone. Panel thickness, depending on the manufacturer, is from 10 to 15 mm. Weight - 15-20 kg / m². The material is the heaviest of all siding types. It requires the arrangement of a reinforced crate. Possesses high performance characteristics:

- resistant to biological and normal corrosion, not susceptible to damage by rodents;

- has an insignificant coefficient of thermal expansion, there is no need to form temperature gaps during installation;

- has a high resistance to mechanical damage;

- maintainable. Unlike metal and polymer siding, a damaged element does not require replacement. With due diligence and skill, the place of damage can be repaired with ordinary cement and painted over.

Basement

Ground siding is used for cladding foundations and basement floors of the building... It is exposed to more intense mechanical stress. In addition, it is strongly influenced by various mineral and chemical substances dissolved in groundwater. As a rule, it is made of polymers and fiber-reinforced concrete, therefore it has similar advantages and disadvantages.It must be allocated in a separate category, since the thickness of the elements is significantly increased to withstand mechanical stress.

Video: what is brick siding

Selection features

The choice of "brick" or "stone" siding is based on the analysis of the following main criteria.

- Influence on the supporting structures of the structure. By this parameter, siding can be divided into two categories. Lightweight - metallic and vinyl. Does not significantly affect the supporting structures of the building. It is recommended to use it if it is necessary to finish large areas of the facade of the structure. Heavy - fiber cement siding, usually used in the decoration of low-rise buildings made of concrete and brick. And also for cladding foundations and basements of any structures.

- Design meets value. Uniform color is a budget siding option. As a rule, it imitates a brick. At the same time, the image of masonry seams, as well as the texture of the material, is applied to the surface without any relief. With highlighted seams - mid-range. The joints of the "masonry elements" are embossed and highlighted in more intense color. Embossed cladding is the most expensive. As a rule, it is made of thick-walled high quality acrylic or fiber cement. Fully imitates the texture of natural materials. Additionally painted in several colors.

Metal and wooden battens for attaching siding are very similar in appearance, but differ greatly in their bearing capacity

Important! Vinyl siding has one more important criterion for selection. It is decorated.

Decorating can be done in several ways:

- Application to the surface - such a decorative coating can be easily damaged, after which the finishing element needs to be replaced;

- Dyeing in bulk - pigments are added to the raw materials during the production process and the color of the siding is the same throughout its thickness.

Advantages and disadvantages

Regardless of the material of manufacture, the following factors can be attributed to the advantages of "brick" or "natural stone" siding:

- durability and resistance to most aging factors: exposure to ultraviolet radiation, abrasion, etc.;

- resistance to external natural manifestations: rain, snow, temperature changes in a wide range;

- high resistance to chemical corrosion - to the effects of mineral salts from groundwater;

- non-susceptibility to biological corrosion: fungus, mold, rot;

- resistance to damage by rodents, from high (polymer siding) to absolute (fiber-reinforced concrete and metal siding).

- durability - the declared service life, depending on the material and manufacturer, is from 40 to 50 years;

- high speed and ease of installation - much faster and cheaper than facing with natural stone or finishing tiles for brick;

- ease of care. It is especially convenient if the house is located near busy highways. You can clean the facade of the building by watering it with an ordinary garden hose;

- a wide variety of colors and textures imitating natural materials and bricks of various formats.

Of the disadvantages of brick and stone siding, it should be noted:

- some types of siding (fiber-reinforced concrete) require additional reinforcement of load-bearing structures;

- polymer siding is a combustible material and requires some experience during installation work;

- metal siding needs additional anti-corrosion treatment of the cut ends.

Some budget models of metal finishing panels have an extremely presentable look, especially when facing large areas

Leading manufacturers and characteristics of their products

There are many domestic and foreign manufacturers of siding imitating stone or brick. Usually these ventures are joint ventures.Their products are not inferior in quality to European ones. The cost of domestic products can be 15-20% lower.

Nailite International in 2009 renamed to Exteria Building Products (USA)

Produces vinyl panels in large format 0.47 × 1.13 m. Among the main differences of the product: painting in bulk, expressive relief of seams and front surface. Among the most popular collections in Russia are the following:

- Stacked Stone - natural stone;

- Hand-Laid Brick - brickwork;

- Hand-Cut Stone - Imitates Roman masonry.

ROYAL EUROPA

Polish-Canadian company producing vinyl siding used for wall and plinth finishing. It is a subsidiary of Royal Building Products - the largest manufacturer of polyvinyl chloride building materials. It is produced in two versions: “under the stone” - 0.51 × 1.265 m, “under the brick” - 0.395 × 1.14 m. The color range is limited to white and red shades. The main difference is the color highlighting of the masonry joints.

KMEW (Japan)

KMEW is one of the leaders in the Asian market for the production of fiber cement panels. The finishing material is covered with several layers of protective substances, after which a protective ceramic coating is applied, imitating the texture of natural materials. It is positioned as an elite finishing material with unique performance characteristics, durability and strength. The company offers over 30 collections of stone and brick siding with various textures:

- rubble;

- Roman masonry;

- poly-lithic;

- noodles;

- polygonal;

- torn stone;

- wild masonry, etc.

Each of the collections has a wide range of colors.

Konoshima Chemical Co., Ltd (Japan)

The company produces facade and basement panels made of fiber cement, imitating stone and brick. The main difference of this product is the use of nanoceramic spraying, which gives the finishing coating additional resistance to abrasion, scratches and other mechanical damage. Konoshima siding has improved sound insulation characteristics.

Wandstein (Russian-German enterprise)

Manufactures PVC facade and basement panels. Products are of high quality and dimensional accuracy. Thanks to special additives, the coefficient of linear thermal expansion is significantly reduced (ZugFest technology). The technology of repeated dyeing and high-quality BRILLUX dyes are used, which guarantees a rich color and prevents fading in the sun.

Alta Plastic

Produces PVC building and finishing materials, including basement and facade siding. The most popular collections are:

- Granite - imitates large-format stone blocks. Has a natural color and texture;

- Rubble stone - has a characteristic rounded shape of relief elements;

- Bassoon - the design was developed for stone blocks with an aged texture;

- Canyon - imitates layered stone masonry with a relief texture.

Features of installation work

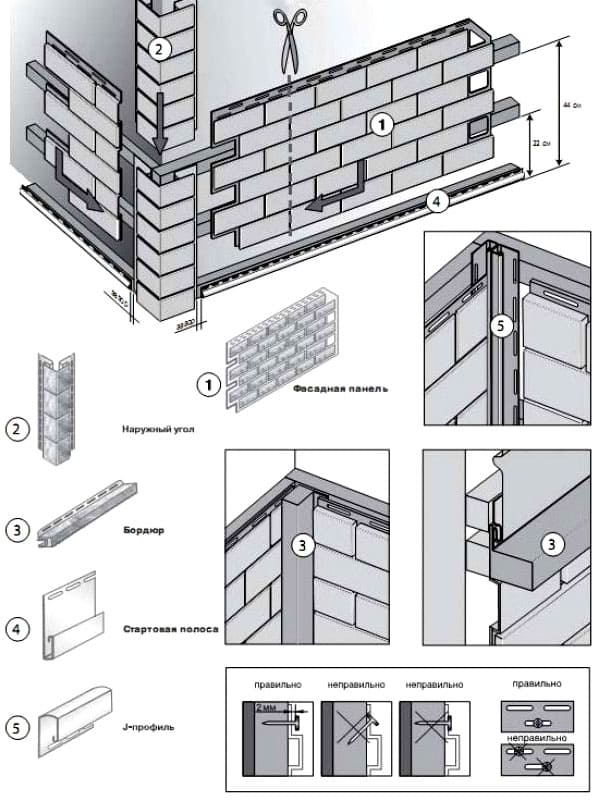

Laying siding requires some skill. However, with strict adherence to the instructions provided by the manufacturer, it is quite possible to do it yourself. No specialized and expensive installation tools are required. Without fail you need: screwdriver, level, for metal siding - scissors for metal. The installation process includes the following steps:

- Substrate surface preparation. Typically, siding is used in ventilated facades to protect thermal insulation. Therefore, the surface of the walls is mostly flat.If a significant excavation is required, defects are filled with a repair mortar.

- Installation of battens. The material used is wooden blocks or profiles for drywall... Bearing elements are installed vertically, with a step corresponding to the dimensions of the finishing panels.

- Installation insulation, hydro and wind insulation;

- Installation of a counter-lattice, which is a clamping strips with a thickness of 1.5-2 cm, installed over the supporting bar to fix the waterproofing membrane.

- Installation of the starting bar. The quality of the entire finish depends on how correctly the starting bar is set in level. Therefore, you should be especially careful when installing it.

- Decoration of window openings - corner strips of window frames are installed.

- Installation of panels. Panel fastening starts from the corner of the wall. Panels of the first row are cut at right angles and tucked into corner profiles. The first panel of the next row is cut in half so that the siding elements are installed with offset vertical seams.

Related article:

Insulation for the walls of the house outside for siding. How to choose a high-quality insulation and what types exist? Read more in a separate publication of our portal.

Important! Regardless of what material the panels are made of, it is impossible to tighten the self-tapping screws all the way, as well as to install siding elements end-to-end. They must have a certain mobility and a small temperature gap.

Related article:

DIY siding installation: instructions for dummies with photos, the benefits of using panels and their varieties, tips and tricks - in our publication.

Calculator for calculating the amount and cost of siding per home

Video: installation of facade panels

Image gallery

Facades of houses with various types of siding finishes:

Summing up

The market for building and finishing materials provides many varieties of siding for every taste in a wide range of prices. Budget-type products have a rather low aesthetic value. They are recommended to be used exclusively as protection of thermal insulation materials for technical structures. For finishing the facades of residential buildings, it is more advisable to use premium siding, which will not only protect building structures and insulation from the negative influence of external factors, but will also become a real decoration of the house.