We build the house ourselves from cinder block: the pros and cons of working with the material

If you are faced with the task of quickly and inexpensively building your own home, pay attention to cinder blocks. This inexpensive building material is deservedly popular with private developers. Its technical characteristics make it possible to create comfortable and reliable housing. The topic of today's review homemaster.techinfolux.com/en/ is a cinder block house. The pros and cons of such a construction, the types of blocks and their purpose, the work algorithm are in our article.

The content of the article

- 1 What is a cinder block, and how do cinder block houses look in the photo

- 2 Pros and cons of cinder block houses

- 3 What can reduce the pluses of cinder block houses, and how can you solve the problems with the minuses

- 4 Characteristics and dimensions of different types of cinder blocks

- 5 What type of cinder block is better to use for building a house

- 6 Which is better - buy cinder blocks or do it yourself

- 7 How to build a house from a cinder block with your own hands: highlights

- 7.1 How to calculate the number of cinder blocks for building a house

- 7.2 How to lay the foundation for a cinder block house

- 7.3 How to properly lay a cinder block on the foundation: video instruction

- 7.4 How to build the walls of a house yourself - features of laying cinder blocks

- 7.5 Roofing and interior decoration

- 8 What is better to choose for construction: brick or cinder block

- 9 How to calculate the cost if you decide to build a house from cinder blocks yourself

- 10 Prices for the construction of "turnkey" houses from cinder blocks

- 11 Cinder block house: the pros and cons of the decision

What is a cinder block, and how do cinder block houses look in the photo

Cinder block is a building stone prepared by pressing from cement and filler. Mass production of cinder blocks is developed in regions with metallurgical production. It is there that blast furnace waste is actively used in the manufacture of building materials. The first part of the name, slag, may have a non-literal meaning. It is understood as stone rubble, crushed glass or bricks, expanded clay, shavings and sawdust, ash, ash, sand.

The technical characteristics of this building material directly depend on the type of filler. The most durable are blocks of rubble and pebbles.

Note! The strength of cinder block building material is indicated by its brand and ranges from 35 to 125 kg / cm².

The minimum strength value, 35 kg / cm², is suitable for additional insulation of load-bearing structures or the construction of low fences. Grade 50-75 kg / cm² is suitable for internal partitions, 100-125 kg / cm² - material for foundation and bearing walls. The cinder block can be used in the construction of structures that have constant contact with water.

Attention! The use of industrial waste in the manufacture of this building material makes it unsafe for humans. It is not recommended to use fresh slag as a filler; it must "weatherate" in the open air for at least a year.

Pros and cons of cinder block houses

Construction material from production waste has its advantages and disadvantages. Before you make a choice in its favor, carefully study all sides of the coin.

| pros | Minuses |

|---|---|

| Suitable for the construction of low-rise residential and commercial buildings. | Long period of formation of blocks in the manufacturing process. |

| A wide range of applications due to the variety of block types. | Masonry from this material shrinks after a few months. |

| Excellent heat-saving data, allowing the blocks to be used for construction even in the Far North. | Blocks can crack during masonry. |

| This building material is easy to cut into pieces. | High strength material needs additional insulation. |

| Hollow blocks significantly reduce the load on the foundation. | |

| High fire resistance, resistance to moisture and fungal growth. | Simple manufacturing technology has led to the appearance of low-quality material on the market. |

| Excellent paronizability of the blocks contributes to the creation of a comfortable indoor climate. | |

| This building material is one of the cheapest. | The use of waste from boiler houses and blast furnaces makes this building material environmentally unsafe. |

| Cinder blocks can be made by hand. |

Think before you decide on a cinder block construction. Such houses need additional protection measures, their construction should be kept under strict control, taking into account the shrinkage and self-destruction of blocks

What can reduce the pluses of cinder block houses, and how can you solve the problems with the minuses

We found out what cinder blocks are and their advantages and disadvantages. How to make the most of the useful qualities of this building material and minimize losses? The main way is to choose the right product, avoiding widespread defects. How to do it:

- Purchase blocks only from a trusted seller. In such a point of sale, there must be quality certificates for the product indicating all its technical characteristics.

- Find out which filler is used in the production of blocks. Do not buy granite screening material for residential buildings, it may have an increased radioactive background.

- A high-quality block should have clear geometric shapes. Carefully inspect the batch for cracks and chips, selectively measure several elements, whether they correspond to the declared parameters.

- A simple check of the block for strength - sticking a regular nail into it. If the nail went in without using a hammer, don't buy. Try to manually break one product - if the production technology is violated, the blocks fall apart with little effort.

- Transport purchased building materials only on pallets.

Characteristics and dimensions of different types of cinder blocks

Different types of fillers and shapes divide blocks into several basic types. Some of them are suitable only for the construction of garages, fences and other outbuildings.There are blocks that are used for insulation or cladding, and there is a high-strength material that can withstand heavy loads. How not to be mistaken in this diversity?

Durable monolithic cinder blocks

The solid element made of filler and cementitious is highly durable. It can be used in any supporting structure: supports, foundations, columns and basements.

This material is not used for the construction of walls, since it has low thermal insulation characteristics.

Slag concrete foundation blocks are especially in demand. But you need to remember that they can shrink and need reliable protection from the effects of groundwater.

Lightweight hollow cinder blocks

Blocks can have voids in their structure - oval, round, square or rectangular. The size of such voids is about a third of the volume of the building element.

The most common question: how many bricks can fit in a cinder block? Standard block dimensions: 39 × 19 × 18.8 cm. Thus, there are approximately 6 single bricks in one volume. If we compare the thermal conductivity of the material, then one block is equal to 12 bricks.

Decorative cinder blocks

There are two types of decorative slag material:

- Colored element - dye is added to concrete to make it. Such material can be used to make fences, wall decoration or support.

- Facing block - has a more complex manufacturing technology that allows you to simulate the surface of a natural stone or plasters... The outer layer of the elements is covered with a protective layer.

Decorative cinder blocks are rarely used - there are a lot of other materials for facade decoration that look more presentable

What type of cinder block is better to use for building a house

Each of the listed types of slag building materials has its own purpose. Hollow blocks are used for walls. If the percentage of voids is within 30, you can use blocks to build a house with two to three floors. If there are more voids - only in one-story construction. Such elements retain heat well, but, unfortunately, do not differ in strength.

Hollow elements are not suitable for the basement and foundation of a building. Only monolithic products can be used here. A properly selected building material will help you build a solid, solid and durable home. So if you still doubt whether it is possible to build a house from a cinder block, leave your doubts. Of course, you can, you should only carefully consider the selection of high-quality building materials.

Which is better - buy cinder blocks or do it yourself

You will find many rave reviews from buyers of cinder block equipment. They say that with the help of a small vibrocompression machine, you can not only build your own house literally for a penny, but also start a profitable business. Take your time to buy the device, not everything is so simple.

On the one hand, if you have a source of material for the blocks, for example, a boiler room nearby, why not use this opportunity? In this case, you will get the main filler for free, since the boiler houses are happy to get rid of waste. Another good option is communication with the sawmill.

Wood chips, sawdust and shavings can also be used as filler. For the bundle, you can use the material at hand

It doesn't have to be concrete. Lime or clay, gypsum - all this is also material for cinder blocks. Now for some practice. First, it is not easy to properly balance the composition of the mixture.Too little binder, too much filler, or the wrong consistency - the blocks will be brittle. You will have to spend some time and money until the correct composition is found. Second, if you don't use free material, but buy it, the blocks will come out not much cheaper than the factory ones, and maybe even more expensive. A large manufacturer purchases raw materials in bulk, in large volumes. As a result, it costs him less.

People who have tested the manufacture of cinder block in practice, speak of profitability in the range of 15-20%

And the last - even if you have a concrete mixer for preparing the mixture, you will have to spend a lot of time and effort on the production of this building material. It is necessary to transfer more than one ton of sand and rubble, wait until each batch is worked out, and until it stands to become suitable for masonry. As a result: savings of 15%, a large percentage of defects due to lack of experience, a sore back and a lot of wasted time. Once again, think about whether the benefits obtained are so significant.

How to build a house from a cinder block with your own hands: highlights

The construction of cinder block buildings is a simple process. Such structures are much faster and easier to build than from ordinary bricks. The main thing is to correctly calculate and follow the general building rules.

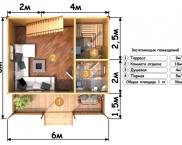

How to calculate the number of cinder blocks for building a house

Savings in construction are achieved not only by using cheap building materials, but also by correctly calculating their amount. It is better to buy more blocks if there are not enough of them than to puzzle over where to attach the extra ones. What are the indicators of the calculation? The first is the thickness of the cinder block wall. It depends on the region of residence. For the south and central part of Russia, it is permissible to put external walls with a thickness of 20 to 40 centimeters. For northern regions, at least 60 centimeters is required.

The second important indicator is the dimensions of the building (width, length and height of the building)

How to calculate the number of cinder blocks in 1 m²: for laying one row, 12.5 pieces of blocks of a standard size are required. If the wall thickness is 40 centimeters, two rows are required, which means that we multiply the number of elements in one row by two - we get 25 pieces. If you need a wall of 60 cm, multiply by three.

Even a second grader can calculate the total wall area: you need to multiply the length by the height. For example, if the wall of the house has dimensions of 10 × 4, then we have 40 m² of masonry. Laying in two rows: 40 × 25 = 1000 blocks. Do I need to subtract the area of door and window openings? If you have regular, medium-sized windows planned, do not subtract them from the total area.

How to lay the foundation for a cinder block house

A cinder block house requires a high moisture-proof foundation. It is required to protect the wall material from contact with groundwater... For one-story and two-story buildings without reinforced concrete floors, there is no need to make a reinforced base.

The cinder blocks themselves are not heavy and do not exert an increased load on the foundation, but the base must be reinforced in any case

Related article:

Types of foundations for a private house. How to choose the right type of foundation and materials for it, step-by-step instructions for building a house with your own hands - read in our publication.

How to properly lay a cinder block on the foundation: video instruction

Blocks are first placed on the moisture-proof layer of the foundation in the corners. The correctness of their location is carefully checked by the building level.Only after setting the corners between them is the cord pulled, and the wall masonry will be built along its line. In practice, it looks like this.

How to build the walls of a house yourself - features of laying cinder blocks

The peculiarity of construction work with cinder block is that they can only be carried out in good weather at a temperature of at least + 15 ° C. To preserve the thermal insulation properties of the material, it is necessary to make seams no thicker than one and a half centimeters and in no case fill the voids in the blocks with a solution. The elements are stacked with an offset of half a stone.

In every fourth row, reinforcement must be done. To do this, recesses are made with an electrofusion cutter, pieces of reinforcement are inserted, and cement mortar is poured. This technique allows you to make the walls much stronger.

Roofing and interior decoration

In the construction of a cinder block building, an important point is the installation of a roof. This should be done as quickly as possible so that rain or snow does not hit the walls. If for some reason you do not have time to cover the roof before the rain starts, use at least a temporary moisture protection: polyethylene or any other covering material.

In any case, the facade of the building will need decorative finishing... If internal insulation is required, a vapor barrier is first mounted, and from above - mineral wool or expanded polystyrene plates... The walls in such a house can be plastered, sheathed with plasterboard and OSB plates.

What is better to choose for construction: brick or cinder block

The cinder-concrete house has its pros and cons, but, in comparison with a brick one, oddly enough, it wins. The cinder block has a porous structure and holds heat much better than a brick. Brick also has excellent thermal insulation qualities, but it will take a very long time to heat a cold house from this material.

A cinder-concrete wall weighs less than a brick wall, which means that there is no need for a reinforced foundation. It will take longer to build brick walls and the cost of the work will be much higher. Again, the cost of a cinder block is lower than the cost of a brick.

Cinder block loses to brick in terms of the durability of the building, but with proper exterior and interior decoration, it will serve more than one generation of home owners

Related article:

Dimensions of red brick, varieties and areas of application, weight depending on the purpose, quantity in a pallet, price per piece of a particular brand and type, video about the manufacture - in our publication.

How to calculate the cost if you decide to build a house from cinder blocks yourself

There is nothing special about budgeting for the construction of a cinder block house. We talked about calculating the amount of wall material, so it's not difficult to calculate the cost of building materials for this part of the construction site. But remember that, in addition to the walls, you will need to invest in the foundation, roof, interior and exterior decoration, and the necessary communications.

You will not find a calculator that will give you a complete calculation. The budget will be formed depending on the prices of materials in the region, the cost of construction services, or, if you are going to do this work yourself, the purchase of the necessary tool.

In short, if you want to estimate future costs, look among your friends and acquaintances for those who have recently mastered a similar construction site. Ask local construction companies for turnkey prices. You can safely reduce their amount by a third - about how much it will cost you to build such a house with your own hands.

Prices for the construction of "turnkey" houses from cinder blocks

The cost of erecting a turnkey cinder block house in June 2018 is in the range of 18-20 thousand rubles per m².If you order an individual project, you will have to pay an additional 20-35 thousand rubles for it.

The price may increase if your site is located in a hard-to-reach place or the necessary communications do not pass near it

Cinder block house: the pros and cons of the decision

A cinder-concrete house has many advantages, and the main one is its cost. During operation, you will appreciate the comfortable climate and warmth, ease of decoration and repair. The main thing is to choose a quality material and check it for the presence of background radiation.

If you have experience in the construction of such houses, write us about it in the comments!