How to build a house from concrete panels

When a person thinks about building his own house, he has to solve two main questions:

- Choose a material for walls, partitions and floors;

- Decide on the layout and number of storeys of the house.

Some materials, for example, brick or cinder blocks, allow you to create a house with any arrangement and even room configuration. Others, such as logs or reinforced concrete products, by their dimensions affect both the size of the rooms and their configuration. In this article, we will discuss how to build a house from concrete panels. Let's make a reservation right away that more often such products are reinforced concrete.

The content of the article

House made of concrete panels and its layout

The choice in favor of a house made of reinforced concrete is influenced by the presence near the construction site of a plant of reinforced concrete products (concrete goods) or a house-building plant (DSK), producing parts for individual construction. You can, of course, apply typical constructions, but this will impose certain restrictions on house layout.

Panels are different

By choosing panels to build a house, you need to know and understand what differences exist between them.

Reinforced concrete factories, for example, often manufactured parts for industrial facilities and social facilities of typical construction - kindergartens, schools, cultural centers, shops ... The use of these structures for the construction of a residential building is associated with the use of such details as columns, crossbars, beams. And this, in turn, causes not entirely justified, unnecessary volumes of interior finishing work, and for the interior, concrete panels of such series are not the best choice.

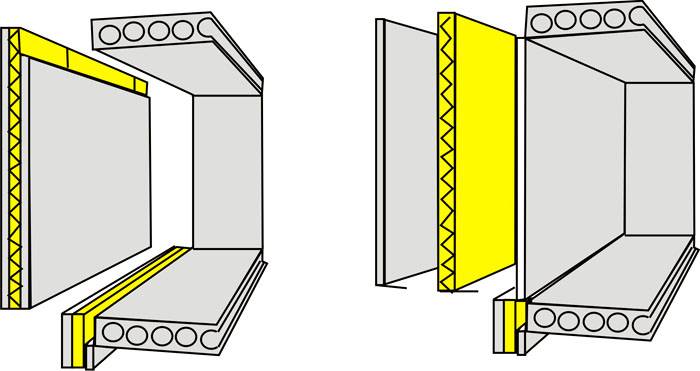

The fact is that panels from a precast plant are usually not self-supporting. They are intended for “sheathing” the building frame made of columns, crossbars or beams. Thus, outside the building is obtained with smooth walls, and the columns and crossbars "stick out" inside the premises and they have to somehow "hide".

DSK produce products directly intended for the construction of residential buildings.As a result, the house gets smooth walls, ceilings and right angles without protrusions and drops. This greatly simplifies the finishing work and, subsequently, the placement of furniture.

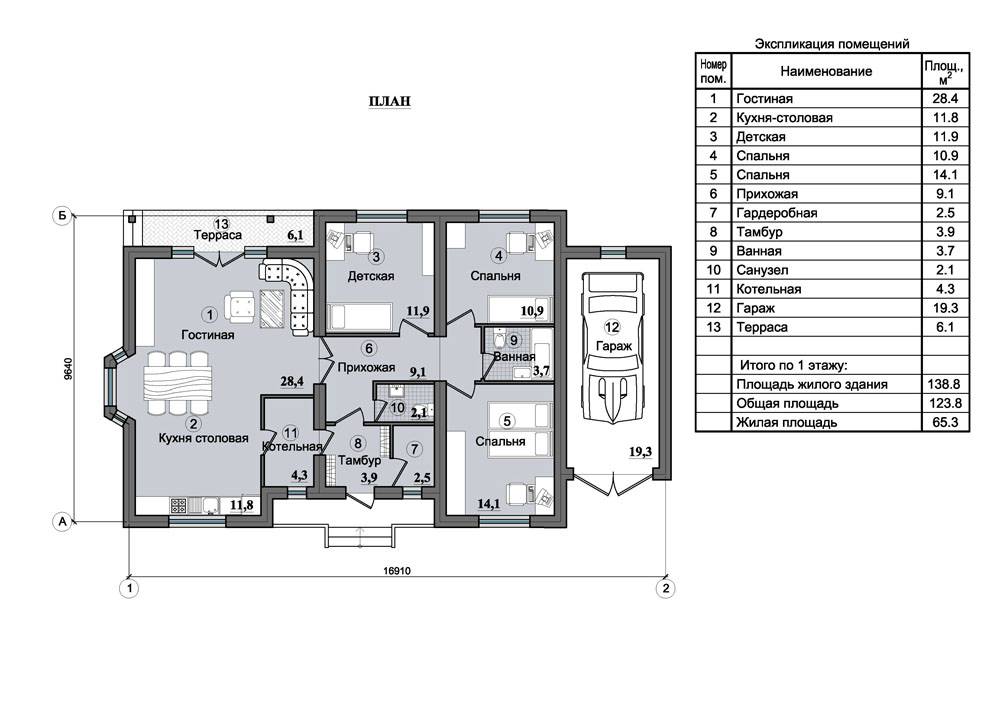

House layout

The most significant drawback of typical reinforced concrete parts in the construction of residential buildings is their rigidly specified dimensions. Reinforced concrete products may not be sawed, cut or chopped. Any rough forceful intervention aimed at changing the size of the part will inevitably lead to a violation of its integrity, to the appearance of cracks, and, ultimately, can cause the destruction of an already constructed building.

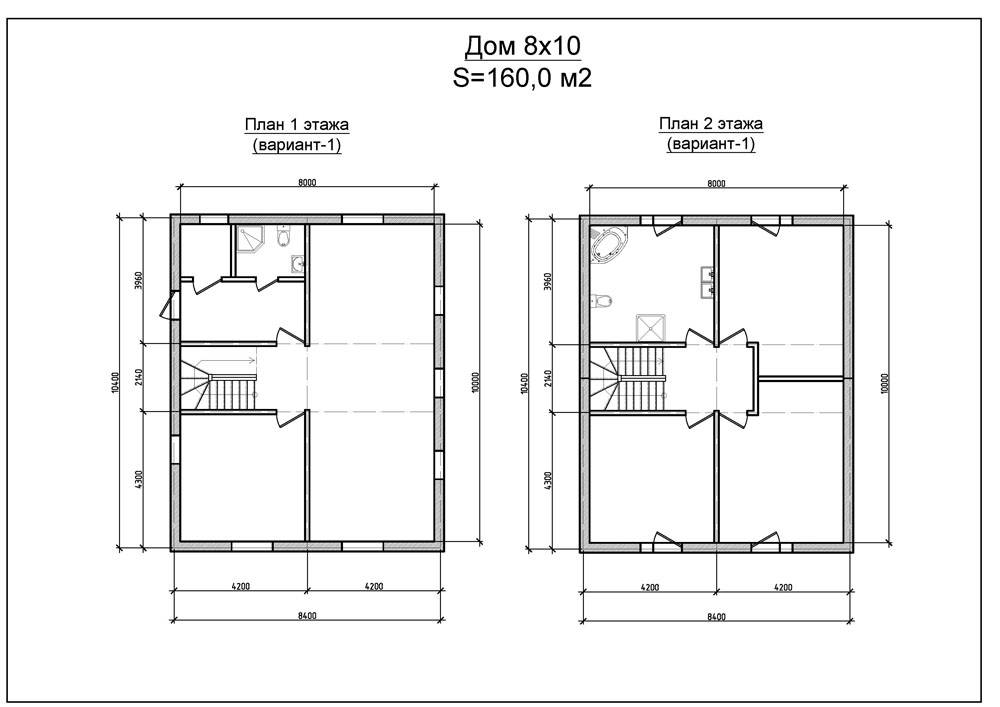

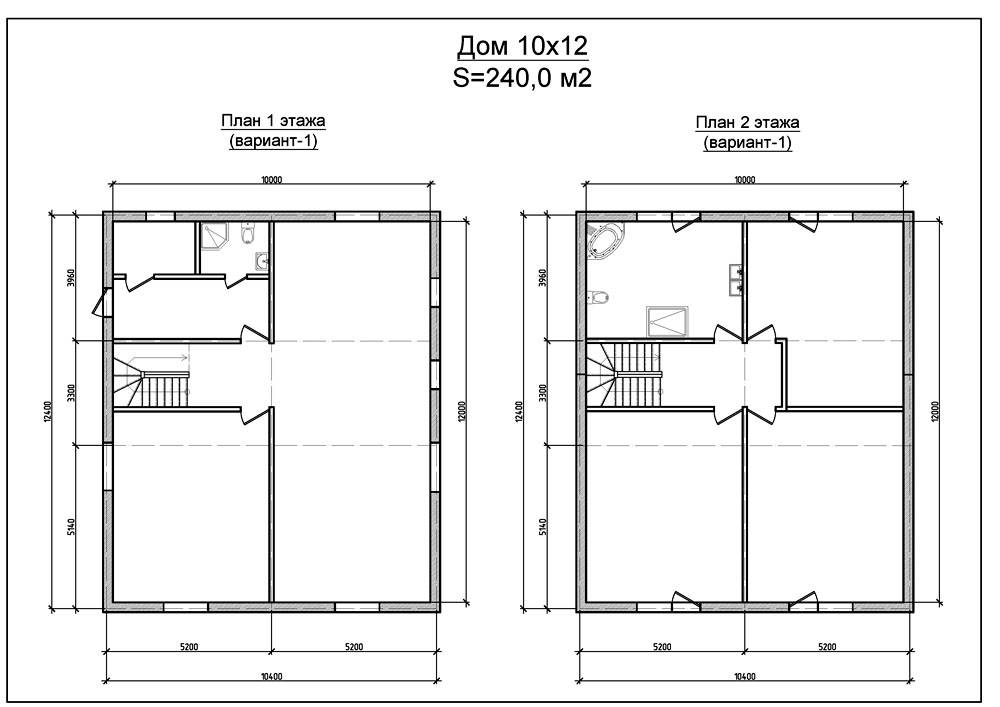

Therefore, before composing House project, you need to familiarize yourself with the dimensions of the parts offered for sale from the supplier of components for houses made of concrete panels. The location of door, window openings in the walls and partitions, as well as - technological holes in the floor slabs. Only knowing these parameters, it is worth starting to draw up a plan for the placement of premises in the house. Especially if the house is planned to be built on two or three floors.

The easiest way, of course, is to develop a house project based on the availability of parts, taking into account their sizes and openings in them. But you can try to select the details, focusing on the desired layout of the future home. Or look for a manufacturer who has the desire and ability to manufacture reinforced concrete parts for a new house project.

Structural differences between panels

In general, all panels are divided into three main types:

- Outdoor wall,

- Internal walls and partitions,

- Overlapping.

In addition to them, other reinforced concrete products are used for the construction of houses:

- Staircases

- staircases,

- ventilation blocks,

- door frames,

- other additional elements.

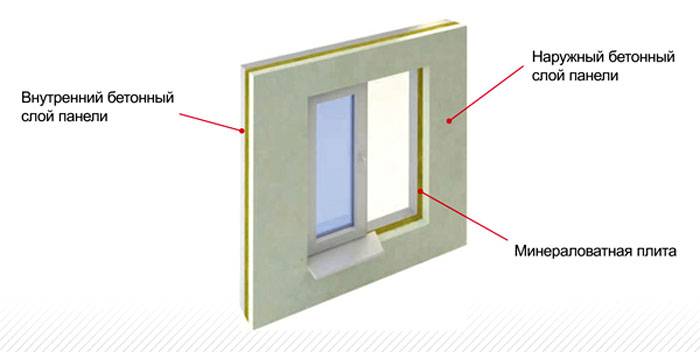

Exterior walls

External wall panels can be one-, two- or three-layer. One of the layers - insulation... It can be expanded clay, aerated concrete, mineral wool, asbestos cement and other heat-insulating materials. The outer layer is high-strength concrete, the inner layer is cement-sand mortar. The thickness of the layers depends on the design solutions of the series of concrete products produced by one or another plant, which, in turn, depend on the climatic characteristics of the building area. The total thickness of the panels can be up to 500 mm. In the climatic conditions of central Russia and the northern regions, the use of three-layer reinforced concrete wall panels is more popular.

Wall panels are also divided into:

- carriers,

- self-supporting,

- hinged.

Already from the names it is clear that the first are the basis of the house, on which the floor slabs are laid. The second ones carry themselves along the height of the building and are attached to the load-bearing walls of the building and floors. The latter are hung on the inner frame of the house, which bears the entire load from the outer walls and ceilings.

The basic design is usually frame from corrugated reinforcement classes AIII and A-IV, which connects all the layers of the panel into one whole.

For concreting, concrete of grades from M25 to M150 and higher is used, depending on the purpose of the layer, whether it is basic, decorative, load-bearing or heat-insulating. All these nuances are described in GOST 11024-84.

Related article:

Table of the proportion of concrete per 1m3. How to prepare high-quality concrete mixes for various purposes. Read more in a separate publication on our portal.

The size of reinforced concrete wall panels can be very different. Their height depends on the height of the floor of the houses for which they are produced, and the width can be calculated for one or two windows. It makes no sense to make it wider because of the difficulties of transportation and storage.

Internal walls

Interior wall panels are divided into load-bearing and non-load-bearing. Ceilings are supported on the first, and hinged and self-supporting external wall structures are attached to them.Non-load bearing ones usually play the role of interior partitions.

The thickness of the load-bearing panels cannot be less than 100 mm; partitions are not produced thinner than 60 mm. Height and width are determined by an individual or standard project. For reinforcement, corrugated reinforcement of classes A-III and A-IV, less often A-I and A-II are used. The concrete grade, depending on the purpose of the panel, can be M-25, M-75, M-100 or M-150 and higher. Internal wall structures are usually single-layer. Their production is regulated by GOST 12504-80.

Concrete wall panel price

When forming a budget for building a house, you need to understand that prices for building materials change regularly, not only depending on the general state of the economy. Each manufacturer has its own pricing policy, which does not always depend on the presence of nearby competitors. Therefore, the price for concrete wall panels may be different for different sellers. Roughly prices can be as follows:

- from 3100 rubles / m² - for single-layer panels,

- from 3650 rubles / m² - for two-layer,

- from 4850 rubles / m² - for three-layer.

Sometimes sellers quote prices for 1 m³, which can mislead the buyer. After all, the volume of the panel depends on its thickness, and the walls are, first of all, square meters. Therefore, speaking of prices, it is always necessary to reduce the conversation to the price per square meter.

Floor panels

Hollow core slabs have proven themselves best in residential construction. The smooth bottom side greatly facilitates the interior decoration of the ceiling of the premises, the roughness of the top side provides good adhesion to the material of the self-leveling floors. The thickness of the slabs is 22 0mm, the length and width can be different. House-building factories also produce solid slabs 120 and 160 mm thick with dimensions that allow covering the entire room with one piece. The technical parameters of floor slabs are set in GOST 9561-91 and GOST 26434-85.

Foundation

When building houses from reinforced concrete panels, the foundation is especially important. As a rule, the foundation for panel houses is of the tape type. It must be strong and reliable, capable of supporting the weight of the entire house. The main parameter is the depth of the foundation. It depends on the level of freezing of the soil in the region of construction and on the presence in the project of the house of premises located below the floor level of the first floor. This can be a garage, cellar, pool with sauna…

The base of the foundation must be below the freezing level of the soil. It consists of a sand cushion on which reinforced concrete foundation cushions are laid. Foundation blocks (FBS) are mounted on them in order, so that the surface of the upper row is above ground level. Then the foundation is waterproofed, and floor slabs are installed under the floor of the first floor. After that, the construction of the walls of the house begins.

Organization of work

Even before designing a house made of concrete panels, you need to think about who and how will deliver them to the construction site, where they will be stored, how they will be installed. This is especially important if the site is small and there are already buildings nearby. It is necessary to determine the place where the crane will stand, with the help of which the installation of structures will be carried out. In the tightest conditions, it should be positioned so that the boom has enough reach to install the panel on the opposite side of the building.

If there is little or no storage space at all, you can organize the work so as to carry out installation "from wheels". To do this, it is necessary to have a place where the car with the details of the house will be within reach of the crane, and at the same time, it will not block the passage to other vehicles.

Currently, it is possible to order the construction of a house on a turnkey basis, when one organization undertakes all the work on its construction and decoration.Prices in this case can also be very different. It all depends on the climate of the region, which will affect the thickness of the panels and the overall cost of insulation, and on the quality of the building materials used.

In general, you can focus on the cost of one square meter. For one-story houses 1 m² will cost from 12,000 rubles and more, for two-storey ones - from 20,000 rubles and more.

The following photos show several options for turnkey houses.

Video: precast concrete kits for prefabricated houses