Aerated concrete house - an overview of ready-made projects and non-standard solutions for individual construction

In recent years, the population of large cities and megalopolises has been trying to live in the countryside in the summer months, which has led to massive individual construction in the countryside and in small settlements, as well as the emergence of entire neighborhoods with low-rise buildings. This trend has contributed to the development of an entire industry in the production of building materials, as well as the emergence of new technologies for individual construction. One of these areas was the use lightweight and durable materials, allowing to reduce the time and cost of construction and installation works: frame construction and pre-fabricated buildings using LTSK technology, as well as the use of light types of concrete, which include aerated concrete. Projects of houses made of aerated concrete, the features of their preparation, which must be taken into account when planning a large construction project - we will tell you in today's review by the homemaster.techinfolux.com/en/ editorial office.

The content of the article

- 1 Features of designing houses from aerated concrete

- 2 What should be included in the project of a house made of aerated concrete

- 3 Review of aerated concrete house projects with a construction price

- 4 How to choose a typical project of aerated concrete house

- 5 How the project is adapted to the construction region and individual preferences

- 6 Features of building a house from aerated concrete with your own hands

- 7 Video: features of building a house from aerated concrete

Features of designing houses from aerated concrete

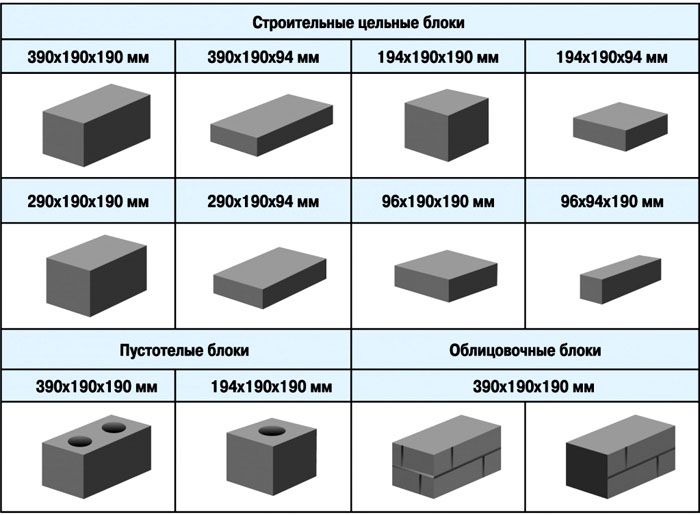

Aerated concrete is one of the types of cellular (light) concrete, which is a porous material, in the manufacture of which mineral binders and silica aggregates are used. To perform construction and installation work, ready-made blocks are used, manufactured in the factory and in this form arriving at the construction site.

Technical requirements for aerated concrete products are regulated by:

- GOST 21520-89 “Small wall aerated concrete blocks. Technical conditions ";

- GOST 31359-2007 "Autoclaved cellular concrete";

- GOST 31360-2007 “Unreinforced wall products made of autoclaved aerated concrete. Technical conditions ".

When designing houses from aerated concrete blocks, the main documents used by designers in their work are the GOSTs listed above, as well as documents such as:

- STO 501-52-01-2007 "Design and construction of enclosing structures of residential and public buildings using aerated concrete in the Russian Federation";

- SNiP II-22-81 * "Stone and reinforced stone structures";

- SNiP 23-02-2003 "Thermal protection of buildings".

In the process of developing project documentation, design engineers take into account the features of this building material, expressed in the following indicators:

- density of masonry and interaction with metal products and structures;

- drying shrinkage and thermal expansion on heating;

- heat capacity and environmental impact.

What should be included in the project of a house made of aerated concrete

Before starting the construction of a house from gas blocks or other building material, the developer needs to collect a certain set of documents, and, although in accordance with the Urban Planning Code (Article 48, Part 3), project documentation for the construction of a house for one family with a height of up to 3 floors not required, however, municipal architecture departments ask developers to provide plans for the facades of the facility under construction. The presence of a complete package of design documentation allows you to avoid mistakes during construction, especially for detailing and complex nodal connections.

The presence of a complete package of drawings will shorten the time of work and save you from overspending of building materials

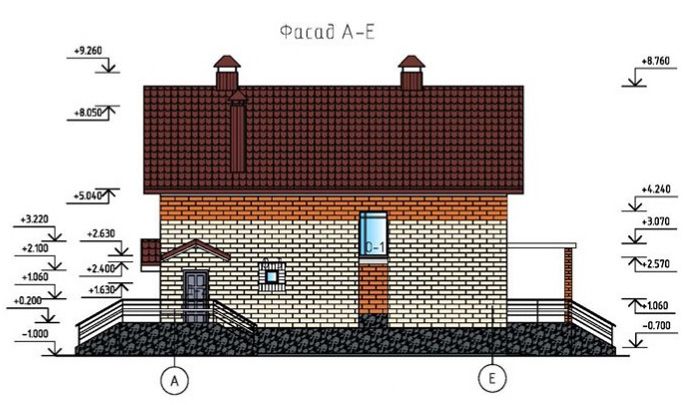

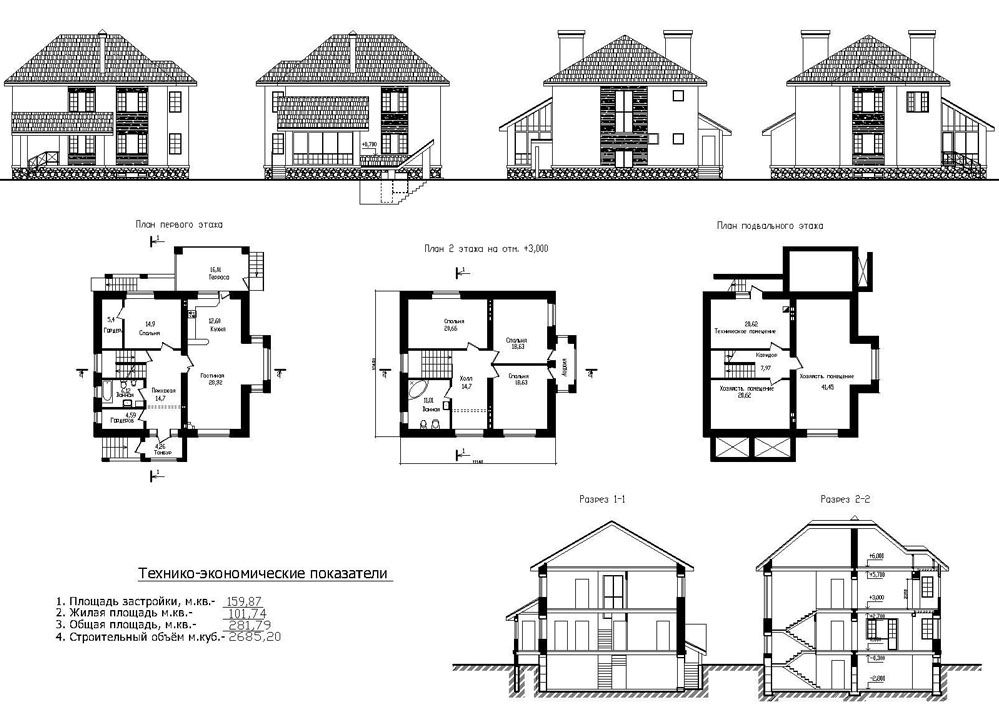

The standard set of drawings includes:

- architectural section - it presents facades in colored design and elements of building decor;

- construction section - it contains floor plans and elements of masonry walls, foundations and roof, methods of finishing and the location of the holes for engineering communications;

- constructive section - can be included in the construction set of drawings or be made separately, it includes attachment points and detailing of various complex structural elements, stairs and windows, doorways and other complex building structures;

- engineering section - the set of drawings of this section includes the following subsections: electrician and communication, heating and ventilation, water supply and sewerage.

In addition, the design documentation may include lists of material requirements and equipment specifications, as well as estimate calculations for all types of work and for the facility as a whole.

The option of offering a ready-made solution offered to a potential developer when choosing a house project

Related article:

House with an attic: projects, photos. Attic buildings are a practical and very attractive idea for a private plot. Projects, photos of successful interiors and recommendations of experienced builders are in our material.

Review of aerated concrete house projects with a construction price

House design engaged in specialized organizations licensed to carry out design work, which reflects the types and categories of objects available for development. In such companies, there are always standard house designs, including those made of aerated concrete blocks, and here you can also order an individual project in accordance with the wishes of the developer, however, this option will be somewhat more expensive than the standard solution. Finished house projects from aerated concrete are offered in the form of brochures or catalogs, which greatly simplifies the search for a house of interest to the customer. In addition, some companies provide turnkey design and construction services, which is also very convenient for developers who are unable to carry out construction work on their own.

Layout and number of storeys, finishing options and other structural elements in different projects can be completely different, therefore, when choosing standard solutions, you should not rush, but approach the issue with special care. Below are some options for typical solutions for houses made of aerated concrete, already successfully implemented in the Russian Federation:

- Projects of houses with a garage.

House project from aerated concrete GB47 with an area of 163.9 m2 with a garage[/ caption] [caption id = "attachment_36317" align = "aligncenter" width = "700"]

House project from aerated concrete GB47 with an area of 163.9 m2 with a garage[/ caption] [caption id = "attachment_36317" align = "aligncenter" width = "700"] Two-storey house with a garage and a "second light"[/ caption] [list type = "check"]

Two-storey house with a garage and a "second light"[/ caption] [list type = "check"]- House projects with carport.

- Projects of combined houses made of aerated concrete and wood.

Related article:

The plan of a one-story house. Projects of houses of different sizes with a basement, a garage and an attic, how to correctly develop a project of engineering networks in a house, useful advice from specialists - you will find in the publication.

How to choose a typical project of aerated concrete house

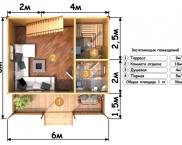

As it was already written above, typical projects are cheaper than individual ones, but with this choice, certain difficulties arise, since such sets of drawings do not take into account the individual preferences of the developer and his wishes. In this regard, when choosing a standard house project, you must:

- Determine its geometric dimensions, which must correspond to the size of the site, the number of storeys of buildings at the location of the house, as well as regulatory requirements for site planning and fire safety.

- To resolve the issue of the availability of the number of rooms and other premises in the potential construction site.

- Think over other wishes: second light, roof structure, etc.

- Consider options for design solutions and evaluate their advantages and disadvantages.

When choosing a standard project, the technical and economic indicators of a construction object are an important criterion that helps to make the right choice.

Having chosen a typical house project, you can order and buy it from a design or other organization, and its cost depends on the number of sets (sections) of this project.

Related article:

Aerated concrete blocks: sizes and prices per piece. What is aerated concrete? How does it differ from foam concrete? Why is this material so popular? Read more in a dedicated publication.

How the project is adapted to the construction region and individual preferences

A typical project does not reflect the personal preferences of the developer, and may also not coincide with the requirements for the construction of similar objects in the region of its location.

In this case, the standard design documentation is tied to a specific construction object, and the necessary changes are made to it. For houses made from aerated concrete, the following types of changes can be made to standard projects:

- increase or decrease window size;

- elimination or other placement partitions;

- choice of others finishing materials of similar quality.

Houses made of aerated concrete blocks are in demand among individual developers, due to the possibility of building with their own hands and the relatively low cost of construction

It is strictly forbidden to make changes related to the violation of the strength of building structures:

- redevelopment of premises with a change in the location of load-bearing walls and structural elements;

- the use of less durable and heavier building materials;

- the change facade designdeteriorating their integrity and other protective characteristics.

Features of building a house from aerated concrete with your own hands

Quite often, individual developers decide to build their own house using aerated concrete blocks on their own, which is explained by such indicators as:

You can build a house of aerated concrete blocks with your own hands, you just need to know the features of construction using this building material

When self-building a house from aerated concrete blocks, in order to avoid mistakes in the performance of work and problems during further operation, it is necessary:

- know about the ability of this material to withstand a significant static uniform load, but collapse under a point dynamic impact;

- blocks made using autoclave drying have better technical characteristics than naturally dried analogs;

- although aerated concrete structures are of a light type that does not require the construction of a powerful foundation, nevertheless, one cannot save money during its construction, because the successful operation of the built house depends on its reliability;

- when installing floor beams, they should not rest directly on a wall made of aerated concrete blocks; in this case, a reinforced belt should be mounted;

- in order to remove the dew point from the inner space of the task, it is necessary insulate from the outside walls, which will also protect them from blowing;

- to calculate the required number of gas blocks, you can use a special calculator;

- the first row of blocks is laid on a waterproofing layer using cement mortar;

- all subsequent rows are laid with an offset of the vertical seams by 1/3 of the block size;

- masonry reinforcement is performed after 2-3 rows;

- if there are no special grooves in the blocks intended for laying reinforcement, then they are cut right at the place of work;

- the laying is carried out in order and in such a way that each subsequent row begins when the previous one is completed;

- the surface of the blocks is cleaned of dirt and dust before laying.

For laying the reinforcement, grooves are cut in the surface of the blocks, if such are not provided for in their manufacture

Building a house from aerated concrete blocks is a work that each developer can do on their own, while the main criterion for its implementation should not be speed, but the quality of the operations performed.

Related article:

In this article, we will consider how to build a house from concrete panels yourself, criteria for the selection of materials, the nuances of the layout of the premises and the organization of construction.