Heating in a private house from polypropylene pipes with your own hands: schemes, installation and prices

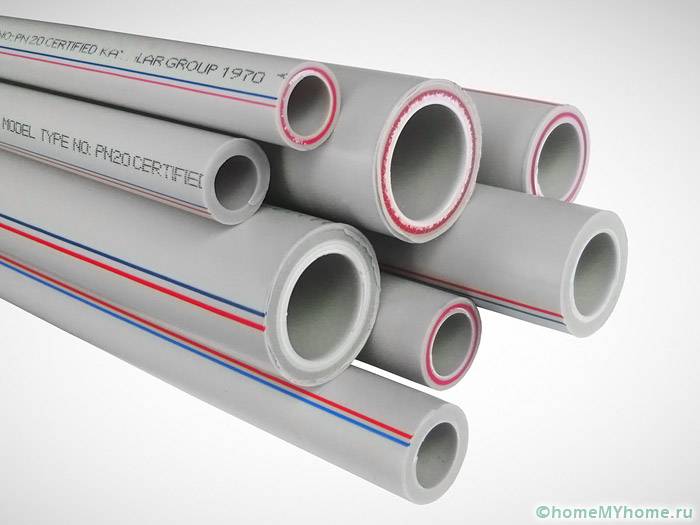

Polypropylene pipes are of high quality and at the same time have an affordable cost, which makes them a popular material. This product has a low thermal conductivity, which allows you to maintain the temperature of the coolant. The ease of assembly of the structure allows you to make high-quality heating in a private house from polypropylene pipes with your own hands in the shortest possible time.

The content of the article

Technical characteristics of polypropylene pipes for heating: features

All the necessary information in the form of marking is applied to the pipe walls. The polypropylene label is designated PP. Also on the surface of the product you can see the following designations:

- manufacturer's logo;

- designation of product modifications PP-random PPRC and PPs;

- working medium pressure and permissible pressure in bar;

- product wall thickness and outer diameter.

Products with internal aluminum foil inserts are used for heating. Reinforcement of polypropylene pipes with fiberglass is also used in heating circuits, hot water supply and in underfloor heating structures.

If the inner layer is made of fiberglass, a slight elongation of the linear sections may occur when heated. Valves and fittings are made from a similar copolymer. The inner diameter of the connecting elements corresponds to the outer section. Clamps are used to fasten vertical and horizontal sections of the pipeline. Connecting and fittings are selected individually for each room.

Some types of polypropylene are suitable for heating. It is a random copolymer, as well as cross-linked polypropylene and a special heat-resistant modification, which is characterized by high thermal resistance.

Note! Sections of polypropylene pipes that pass through partitions and the walls are finished with a pass-through sleeve, which protects the surface from abrasion and prevents material displacement when heated.

Price of propylene pipes for heating: an overview of manufacturers

In the table you can see the price of polypropylene fiberglass-reinforced pipes for heating and other options.

| Manufacturer (Country) | Reinforcement type | Diameter | Cost, rub. per running meter |

|---|---|---|---|

| Sinikon (Russia) | Fiberglass | 32-110 | 30-400 |

| Tebo technics (Turkey) | Fiberglass | 20-160 | 50-150 |

| Valtec (Turkey) | Aluminum | 25-63 | 120-630 |

| Dizayn (China) | Aluminum | 20-32 | 48-500 |

| Wawin Ekoplastic (Czech Republic) | Aluminum | 20-110 | 45-554 |

| Wefatherm (Germany) | Aluminum | 10-20 | 180-450 |

| Aquatherm GMBH (Germany) | Fiberglass / Aluminum | 16-355 | 130-850 |

The pipeline in the diagram

To install a high-quality heating system, a properly executed piping is required. Water is used as a traditional heat carrier. Resistance to high temperatures is the most important indicator of the durability of the structure.

Internal surface properties do not impede flow resistance. The impurities in the coolant do not form deposits. Reinforced with aluminum polypropylene pipes for heating, as evidenced by the reviews of professionals, serve as a guarantee of oxygen penetration into the system. In addition, an interlayer of foil-clad metal protects the heat exchanger structure from corrosion and improves system performance.

Even if the system is frozen, the polypropylene lines will not collapse.

Important! For heating systems with antifreeze no polypropylene pipes are used. They are replaced with steel, brass or copper products.

Nuances of performing heat welding

The installation of structures made of polypropylene products is carried out at a temperature of at least five degrees. For heat sealing, special parts are used.

Heat welding consists of the following stages of work:

- the pipe is cut according to the previously made markings;

- the cut must be cleaned and lubricated with acetone;

- the boundaries of the melt are necessarily marked with a pencil;

- the tool is heated;

- the elements are melted;

- docking of nodes and cooling.

When performing heating in a private house from polypropylene pipes with your own hands, you need to withstand a certain voltage of electric current in a soldering iron. After the joints have solidified, the seams are checked for welding defects and the straightness of the joints. The system strength test is checked after 16 hours have elapsed.

Related article:

Heating a country house: options and prices. A separate review provides a comparative analysis of different heating methods with tips and tricks.

Options for schemes from polypropylene pipes

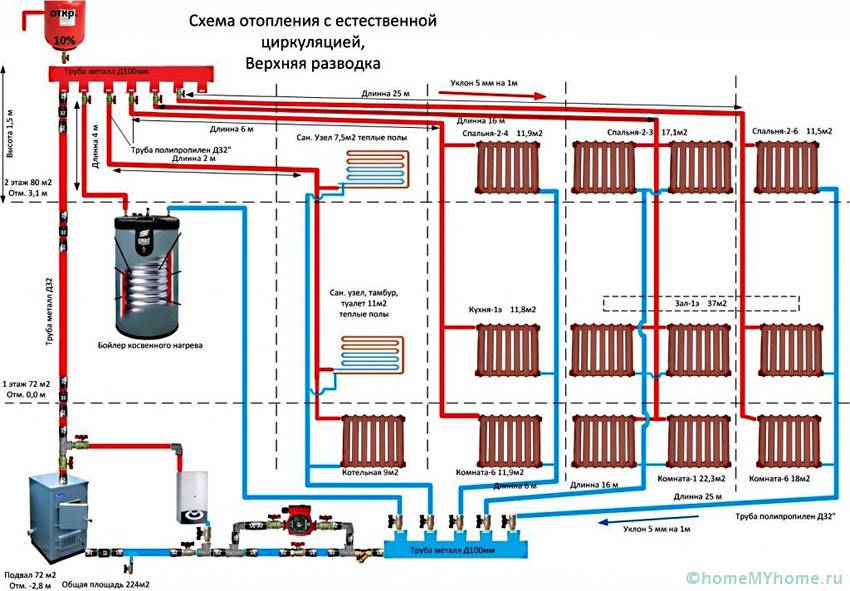

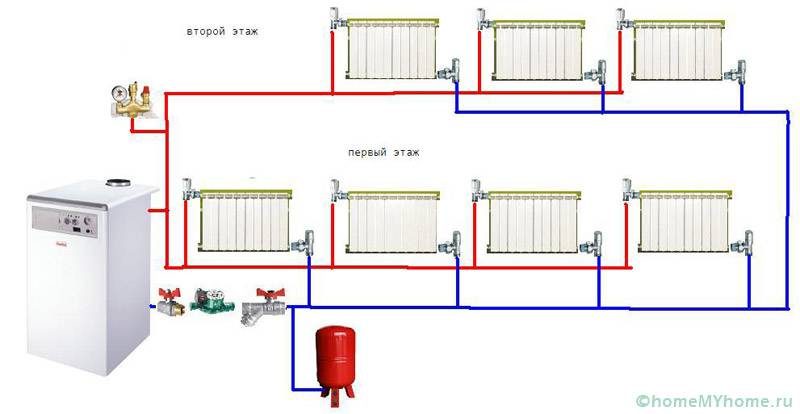

It is important to choose the right wiring diagram. For houses with a small area, the option with natural circulation is used. For buildings of large sizes, a two-pipe distribution system with forced circulation is used.

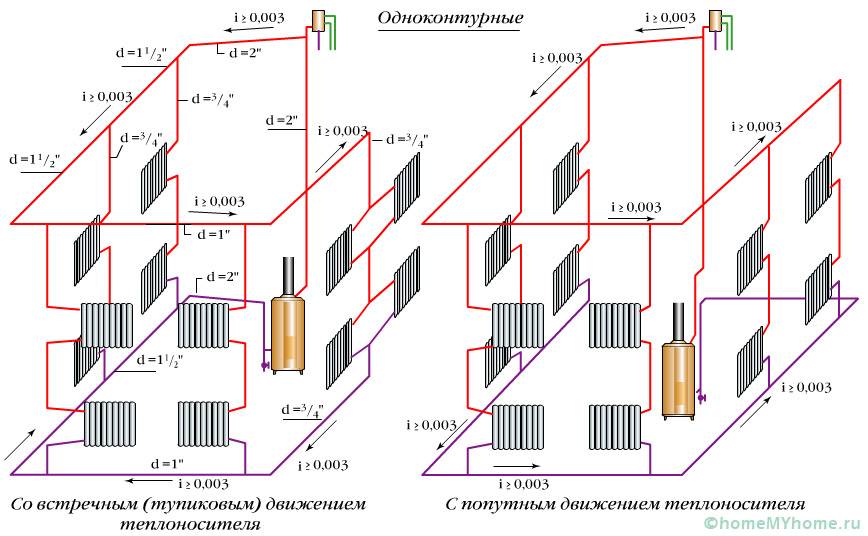

For high-quality piping, it is necessary to calculate the throughput of pipes and determine their diameter. If the heat consumption is calculated correctly, then this will reduce heat losses.Hydraulic calculations can be carried out using a special program. Traditional methods include a one-pipe system water heating private house with your own hands.

Such systems function under the influence of gravitational forces. To increase the flow rate, a certain flow is required. When radiators are connected in series, it is difficult to distribute heat energy evenly. Rooms located further from the boiler will heat up worse.

When installing a heating system in a private house, the following options should be considered:

- a one-pipe scheme is characterized by the fact that the line is connected to each heating device. In this case, the coolant as it moves away from heating boiler loses its temperature, the last radiators will be colder;

- The two-pipe design is distinguished by the separation of the return and supply lines, operating in parallel. This option is used in branched circuits, when it is required to deliver a coolant with the same temperature value to each radiator. In an emergency, you can turn off one radiator or riser.

For a two-pipe design, it is better to design a one-sided connection from the bottom.

DIY heating in a private house from polypropylene pipes

The main elements during the installation of the heating system are the boiler, the pipeline and the generator of the structure. Also, the operation of the equipment is influenced by the safety group, pressure regulation mechanism and expansion capacity.

The circulation pump can be built into the circuit or installed in the return line of the pipeline. The expansion tank structure is mounted in front of the pump.

Helpful information! A powerful boiler is connected to a polypropylene piping through metal. Do-it-yourself heating in a private house made of polypropylene pipes is connected using a manifold comb and a hydraulic separator.

Heating is an important part of any home. The choice of quality material allows you to create the right heating system for a comfortable stay.

Video: polypropylene two-pipe heating system