DIY solid fuel boilers for long burning: drawings and assembly process

Before proceeding with the independent production of solid fuel boilers, it is necessary to prepare sketches. They should reflect the main and additional elements. It is proposed to take the drawings of solid fuel boilers for long burning as a basis. It is quite possible to make them with your own hands.

The content of the article

- 1 Advantages and features of long burning structures

- 2 The process of making solid fuel boilers for long burning with your own hands: drawings and assembly

- 3 DIY solid fuel boiler for long burning: video for acquaintance

- 4 Are there any negative reviews about a solid fuel boiler for long burning?

- 5 On the cost of finished models for heating with solid fuel

- 6 Summarizing

- 7 Video: do-it-yourself long-burning boiler

Advantages and features of long burning structures

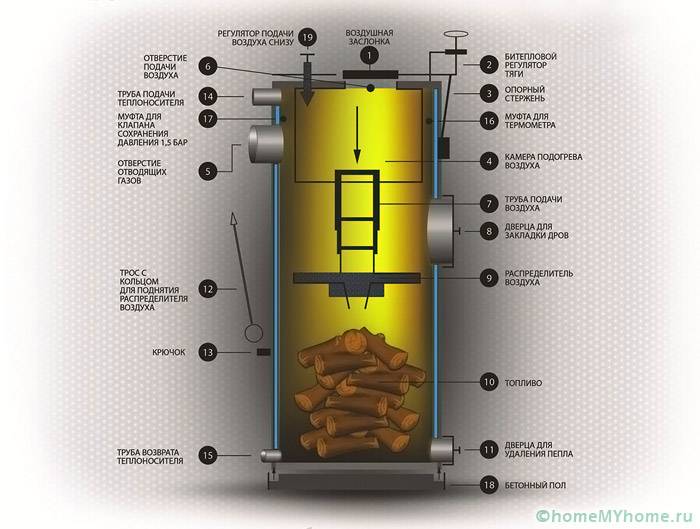

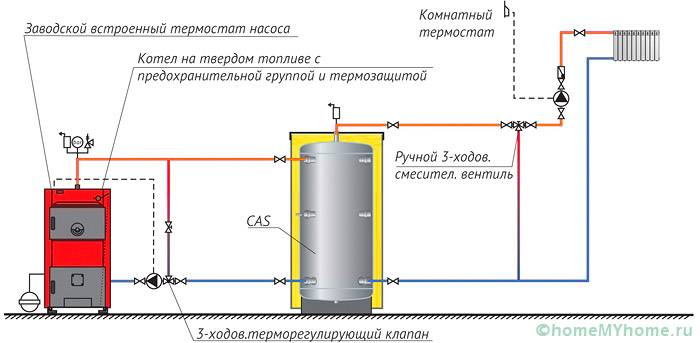

Analogues with support for long-term combustion differ from ordinary boilers by the presence of two working chambers at once. In the first of them, the directly embedded fuel is burned, and in the second, the released gases. The timely supply of oxygen plays an important role. An ordinary fan with simple automation can be used as a device for blowing air.

Of the advantages of the units, it should be noted:

- the minimum number of fuel fillings;

- high work efficiency;

- use of various types of solid fuels;

- a small amount of soot in the pipes during operation;

- design reliability.

Note! Of the shortcomings, it is necessary to mention the complexity of self-production. Although when using ready-made drawings solid fuel boilers long burning with your own hands to make the unit is still real.

The process of making solid fuel boilers for long burning with your own hands: drawings and assembly

It should be noted right away that structures can have both an upper combustion chamber and a lower one.In the first case, the combustion products enter the working compartment under the influence of natural forces, and in the second - with the help of an additional device for forcing air.

Since boilers with a lower afterburning chamber are difficult to manufacture and require the installation of additional equipment during installation, it does not make much sense to consider them. It is faster and more economical to make a design with an upper combustion chamber.

The following describes how to make a long-burning solid fuel boiler yourself using available materials.

Applicable elements

To manufacture the structure you will need:

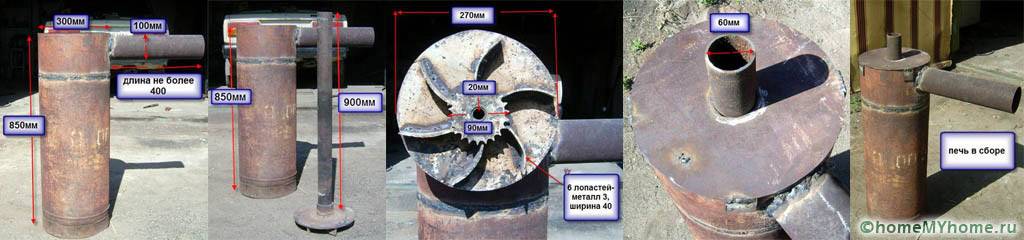

- pipe with a section of 500 mm and a length of 1300 mm;

- pipe with a diameter of 450 mm and a length of 1500 mm;

- pipe with a cross section of 60 mm and a length of 1200 mm;

- two rings 25 mm wide and 500 mm in diameter;

- metal corners and pieces of the channel;

- Metal sheet;

- asbestos cloth;

- hinges and handles.

Body assembly procedure

First of all, pipes with a cross section of 1500 and 1300 mm are nested into each other. They are connected using a ring made from a corner measuring 25x25 mm. A circle with a diameter of 450 mm is cut from a metal sheet and fixed to the end of the pipe. It acts as a bottom. The result should be a small barrel.

On the underside of the structure, a rectangular hole of 15x10 cm is cut for the ash pan door. The sash is attached to the opening with hinges, and a latch is also installed.

A rectangular hole is made just above for the fuel chamber. The dimensions can be determined by yourself. The convenience of loading firewood or other fuel will depend on the correct dimensions. A door with a latch is installed using the same technology.

At the top of the home-made structure, an outlet is made, with the help of which the exhaust gases will flow into chimney... On the sides, by means of welding, the pipes are fixed, which are necessary for connection to the heating system of the building. Threads are necessarily cut in them.

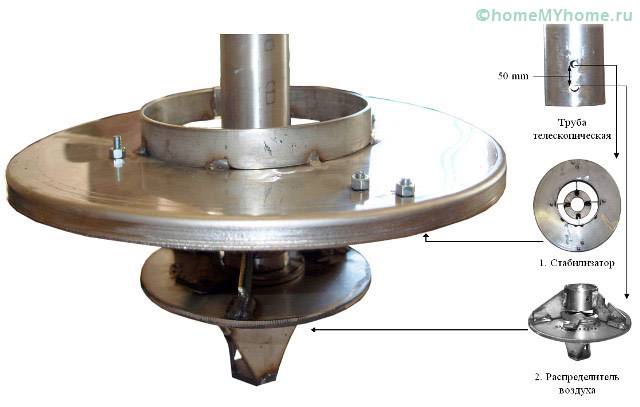

Air distributor device

A circle with a cross-section 20-30 mm less than the diameter of the inner part of the boiler is cut out of a piece of sheet metal. A round hole is made in the central part for the air distribution pipe. Its diameter should be 6 cm. A pipe is inserted directly into the hole and welded to the base.

Pieces of the corner are attached to the bottom of the metal pancake. On the other hand, a loop is fixed by welding, which is necessary to move the structure up and down. To adjust the air supply directly to the combustion chamber, a damper is arranged.

A circle with a diameter of 500 mm, cut from a suitable piece of metal, is inserted into the structure. The upper end of the pipe is inserted into the hole, after which the upper boiler cover is welded tightly. A cable is fixed to the loop, which allows lowering and raising the distributor.

Note! The simplest of all schemes of solid fuel boilers for long burning was presented. It is not so difficult to assemble a reliable structure with your own hands, especially if you have experience with welding and other tools.

DIY solid fuel boiler for long burning: video for acquaintance

Another option is to apply gas bottle for the case. It can be used to create a completely effective structure for heating small buildings. To familiarize yourself with the features of a homemade heating device, it is suggested to look at the video.A long-burning boiler with your own hands without drawings can be made according to it.

Are there any negative reviews about a solid fuel boiler for long burning?

Sometimes consumers leave negative reviews about designs, but they are more likely associated with the general disadvantages that are inherent in solid fuel devices in general.

The following disadvantages can be highlighted:

- to store fuel, you have to use special rooms or structures;

- fuel in any case must be loaded manually, despite the reduced number of loads;

- when installing any model of solid fuel boilers, special safety measures must be taken;

- it is impossible to regulate the process of fuel combustion in the combustion chamber with particular precision.

Note! There are a lot of disadvantages, but still solid fuel boilers are the only way out of a situation when gas and electricity main lines are not available.

On the cost of finished models for heating with solid fuel

If you can't make a long-burning boiler or you simply don't want to, then you can purchase a ready-made structure. It must be admitted that models for heating large rooms are not cheap. In the table you can find the prices for the Stropuva boilers.

Table 1. Prices for boilers Stropuva

| Model | Power in kilowatts | Price in rubles |

|---|---|---|

| S-8U | 8 | 70 000 |

| S-15U | 15 | 116 000 |

| S-20U | 20 | 123 000 |

| S-40U | 40 | 142 000 |

Related article:

Wood burning boilers for home. From this publication you will learn everything about wood-burning boilers, their varieties and nuances of use.

Although the prices for the structures are quite high, they justify themselves during long-term operation. The presented models have a rather stylish design, so there are no problems with implementation in the overall design of the room.

Summarizing

Having carefully studied the drawings of solid fuel boilers for long burning, it will not be difficult to build a homemade model with your own hands. However, you must be able to use welding machine and work with standard tools, otherwise it can take quite a long time to manufacture.

Video: do-it-yourself long-burning boiler