Chimneys for a gas boiler in a private house: how to choose and install?

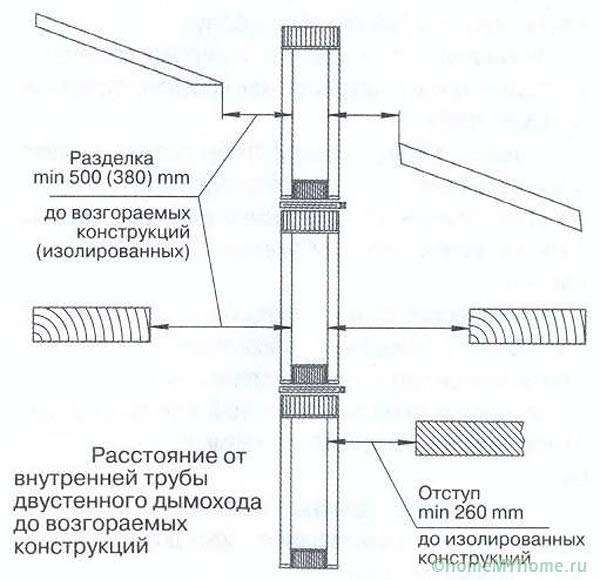

Dfor the removal of combustion products inside the furnace heating appliances chimneys are used for a gas boiler in a private house of different designs from not the same materials. The regulations of SP 7.13130 indicate the requirements for cross-sections, height, location of chimneys, safe schemes of nodes for passing through structures made of combustible materials.

The content of the article

Video: rules for laying a chimney from a boiler

Chimney requirements and installation rules

Combustion products have high temperatures, so chimneys for gas boiler in a private house must fully comply with the norms of SP 7.13130. The use of factory products that have not been certified by the Russian Federation is not allowed.

The main provisions of the fire safety code are:

- internal section of the chimney - 14 x 14 cm - 14 x 27 cm, depending on the heat output of the boiler (3.5 - 7 kW, respectively) for concrete, brick, ceramic structures, round area metal sandwich or asbestos-cement pipes must comply with these dimensions;

- height - 5 m minimum from the firebox to the deflector;

- chimney thickness - 6 cm for heat-resistant concrete, 12 cm for ceramic brick, not standardized for asbestos cement, sandwich.

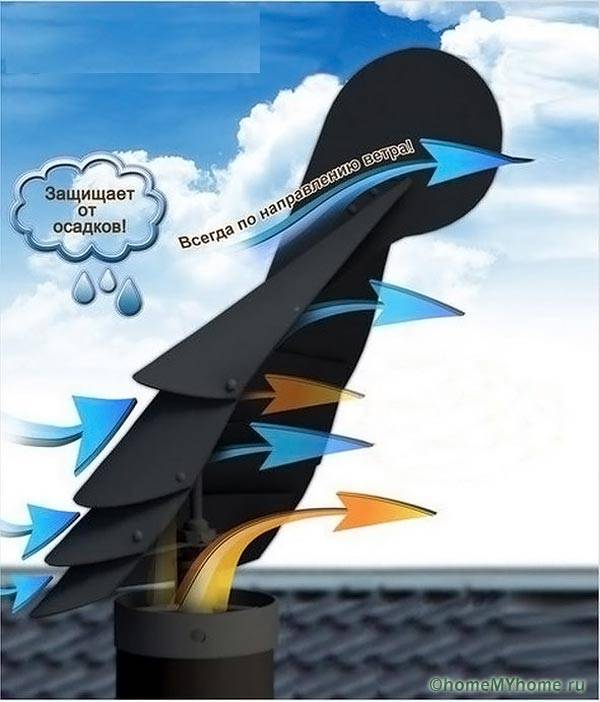

The height of the deflector (umbrella structure that protects the pipe from rain, wind) relative to the ridge depends on the distance between the chimney and it:

- 0.5 m higher at a distance of within 1.5 m;

- flush with the ridge at a distance of 1.5 - 3 m;

- at the level of an imaginary line at an angle of 10 degrees relative to the horizontal drawn from the ridge to the pipe, at a distance of more than 3 m from it.

When removing the chimney outside, bends are allowed within 1 m from the axis of the main pipe to the side at an angle of less than 30 degrees relative to the vertical.The grooves should exceed the thickness of the slabs with decorative ceiling cladding by 7 cm with an even distribution of this size from the bottom / top.

The distances from the external surfaces of structures to the wooden elements of load-bearing structures (lathing, rafters, beams, crossbars) must be greater than the indicated dimensions, depending on the material of the chimney:

- 13 cm - concrete brick, sandwich;

- 25 cm - ceramics without insulation, asbestos cement.

Attention! It is forbidden to combine chimneys with ventilation ducts without a special project. But in one pipe, you can run combustion products from two boilers, if necessary.

Chimney structures

When choosing a chimney or channel, you should focus on the best combination of the budget for the construction of the structure, resource, maintainability. Depending on the materials used, chimneys for a gas boiler in a private house are fastened with clamps to the enclosing structures or rest on separate foundations.

In all vertical structures, a serious problem is the formation of condensate released when hot gases come into contact with cold pipe walls. In coaxial modifications, which are often located horizontally, this minus is absent. In addition, it is enough to give a slight slope of the pipe to the ground so that possible condensation can drain from it without additional costs on its own.

Related article:

Chimney cap. In a special publication of our online magazine, recommendations for choosing a weather vane for different types of chimneys and some installation nuances are presented.

Installation: recommendations and diagrams

Installation of a chimney for gas boiler in a private housee is produced according to the general scheme for asbestos-cement, sandwich, ceramic pipes. For coaxial aluminum, plastic pipes, a circuit is in principle not needed. In the manufacture of masonry from blocks, modules, bricks, standard techniques of stone work are used.

Sandwich setting

Chimneys from two pipes of different diameters, inserted one into the other, with a heat insulator between them are called sandwiches. The design allows you to reduce the external temperature of the walls (increase fire safety), eliminate the formation of condensation (useful for increasing the resource).

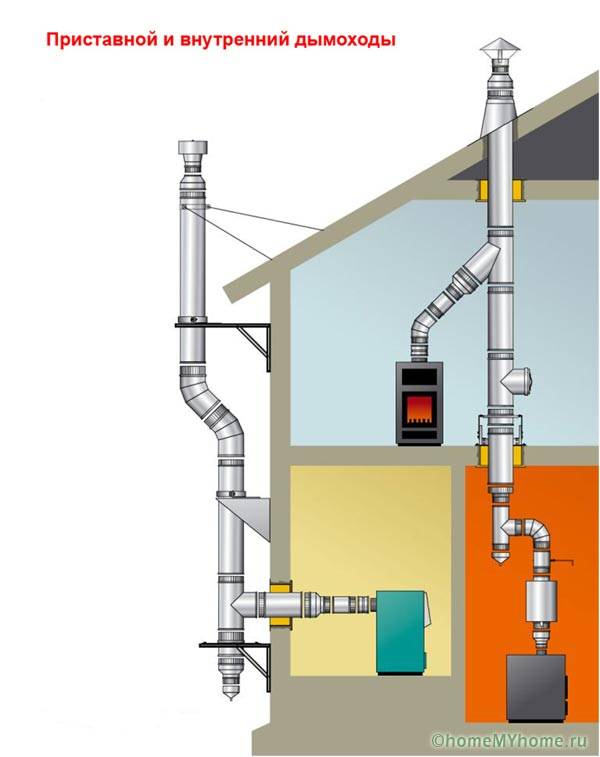

A sandwich chimney of a wall-mounted gas boiler is mounted in a private house using two technologies:

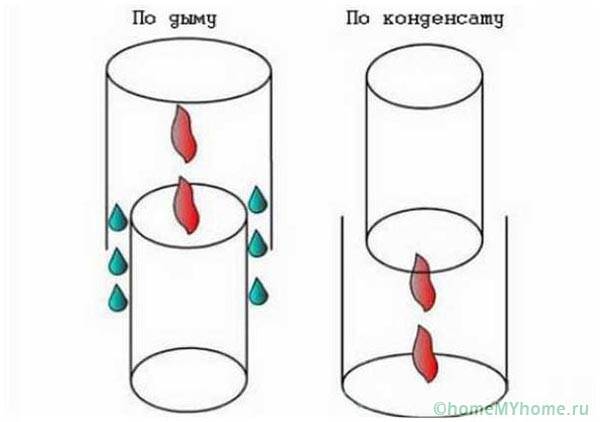

- by condensate - the upper elbow is inserted into the bell of the lower one, when condensate drains in the annular space, its penetration into the channel, ignition is excluded;

- by smoke - the upper pipe is put on the lower one, preventing the penetration of combustion products into the room.

Attention! Gas boilers have low temperature gases at the exit from the combustion chamber. Therefore, the "condensate" technology is used.

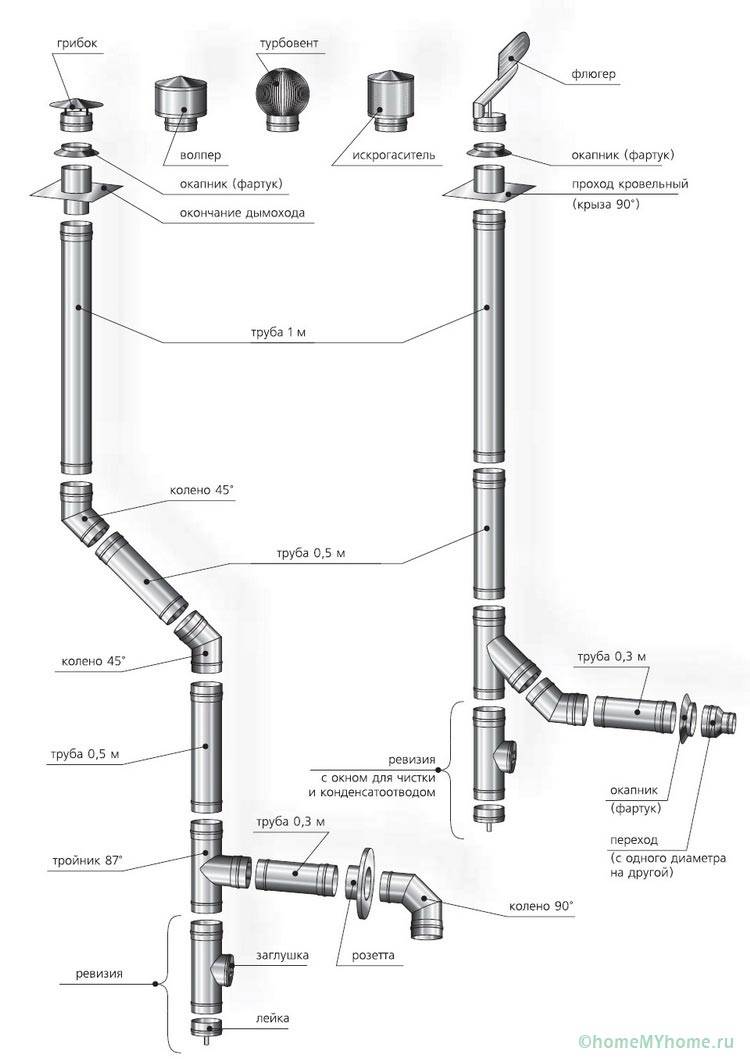

The chimney assembly technology is as follows:

- installation of a gate on the boiler outlet to adjust the section of the flue duct;

- installation of pipes before overlapping "by condensate";

- making a cut from a steel box attached to the floor from below;

- chimney cutting, building up to the roof;

- fastening to the roof lathing - a plate with a conical branch pipe located at the desired angle to it, depending on the slope of the slopes;

- fixing the sandwich chimney pipe to the roof with an entrenchment (conical clamp of complex profile), which decorates and seals the joint.

After that, it remains to install one of the elements at the pipe mouth:

- wolper - deflector to increase traction with a flat cover;

- weather vane - deflector to improve traction of the original design;

- fungus - conical nozzle for protection from precipitation.

These elements are made of stainless steel, fully consistent with the style of sandwich chimneys.

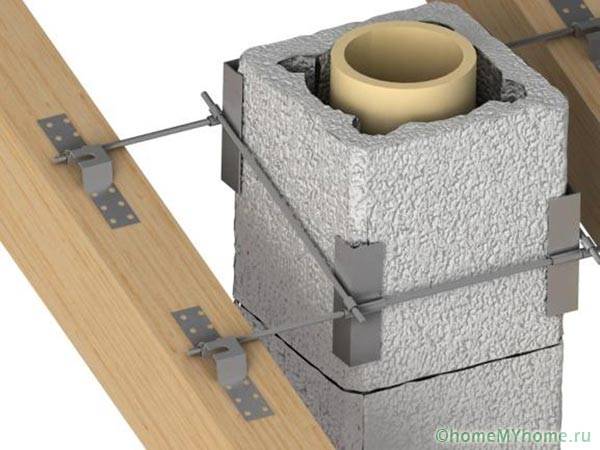

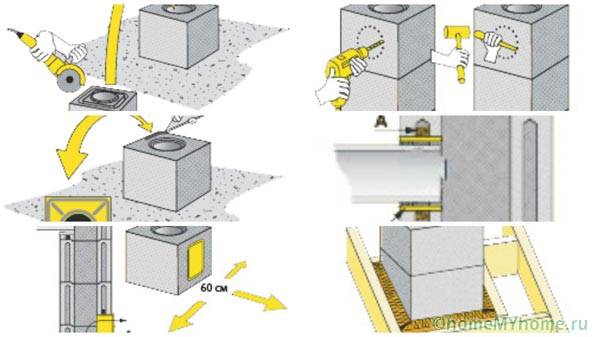

Stone and brickwork

Chimneys for gas boiler in a private house they can be built into brickwork (only into a load-bearing internal wall) or created from blocks. Domestic manufacturers produce several types of chimney modules:

- concrete - used only with ceramic pipes passing inside them, the outer surface is square, the inner surface is round;

- ceramics - pressed out in special forms, then fired in ovens, have the structure of an inner pipe, an outer square thin-walled box, connected by stiffening ribs.

The Ukrainian company Schiedel produces chimney blocks from pumice of volcanic origin. The modules, called Isokern, are a budget option for individual developers. The material is much lighter than concrete, ceramics, the only drawback is the rough inner surface, the lack of Russian certificates. Regional fire safety services accept structures from this material in 50% of cases.

Brick chimneys are built into the walls during the construction of the enclosing structures. For laying blocks, it is necessary to pour concrete into a free-standing foundation. But, the pipes can be placed in any convenient place, there are no problems with the nodes of passage roofs, roof systems, floors.

Asbestos-cement pipe

Aggressive advertising of sandwich chimney manufacturers cites the main disadvantage of asbestos - the lack of environmental safety. In fact, only safe raw materials and technologies are used in domestic production. According to the reviews of the masters who mount all types of modern chimneys, the asbestos-cement pipe has the following advantages:

- is self-supporting - does not need to be fixed to the walls;

- does not condense moisture - there are no leaks inside the combustion chamber;

- resistant to combustion products - the resource is higher than that of concrete, brick;

- cheaper than ceramics - the cost is much lower.

Installation of an asbestos-cement pipe is extremely simple:

- the first pipe is installed on a foundation, secured with racks or a frame;

- the chimney is built up to the required height, the pipes are connected with couplings;

- the top is covered with a deflector, at the bottom a hatch is made for installing the cleaning door.

The boiler feed-in is carried out by a steel elbow, which can be replaced if necessary.

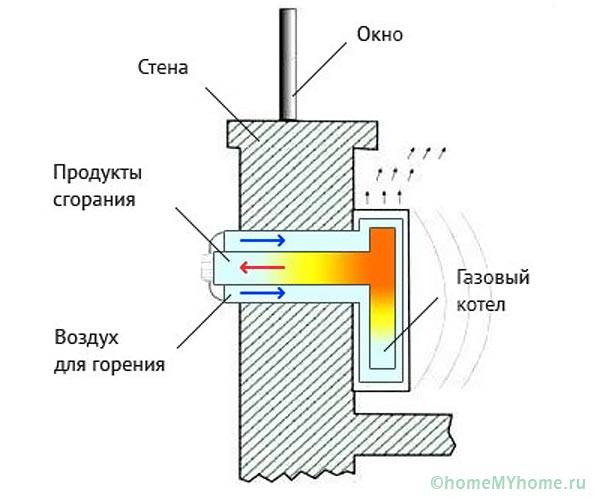

Installation of a coaxial structure

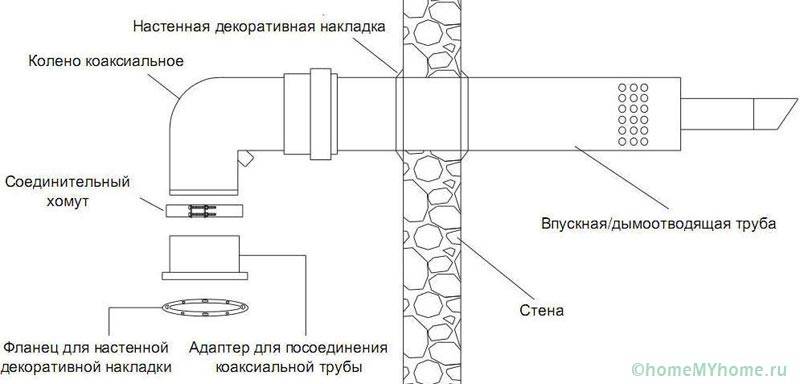

Unlike other versions of the chimney, the coaxial pipe can only be used for closed combustion chambers. Forced ventilation (boost) is a prerequisite for the system. The design of a coaxial chimney is similar to a sandwich, however, instead of insulation, there are jumpers between pipes of different diameters. The inner pipe is used to remove the combustion products, the street air required for natural gas combustion is sucked into the annular space.

Unlike conventional chimneys, the pipe does not need to be pulled vertically through all floors. Instead, a 90-degree bend is put on the outlet pipe, the coaxial chimney is attached to it horizontally, goes out through the nearest wall, observing the fire safety distances:

- the maximum length of the horizontal part is 3 m;

- at least 0.2 m to the ceiling, floor, ground;

- more than 30 cm from the axis of the chimney to the wall surface;

- at least 60 cm from the mouth of the pipe to the opposite wall.

The coaxial structure can be brought vertically above the roof, horizontally through the wall, or connected to a smoke channel built into the brickwork of the wall.

conclusions

Thus, for closed combustion chambers, a coaxial chimney is preferable, saving the construction budget, aesthetics of the roof, in which there will be no holes. The most reliable for open fireplaces are asbestos-cement pipes or sandwiches. The most concealed wiring is provided by built-in smoke channels in brickwork, structures made of concrete, ceramic blocks or Isokern modules made of volcanic pumice.

Video: typical mistakes when installing stoves and chimneys