Long-burning pyrolysis boilers with a water circuit: operation features

TOsolid fuel firing is an alternative to gas and electric heating devices. Long-burning gas generating or pyrolysis boilers with a water circuit are devices that allow you to burn not only solid fuel, but also fuel gases that are released during this process. This principle of energy use is good for the environment and saves fuel. There are also disadvantages - harsh operating conditions and high price. How to determine the golden mean and get the most benefit - in the material below.

The content of the article

Gas generating boilers

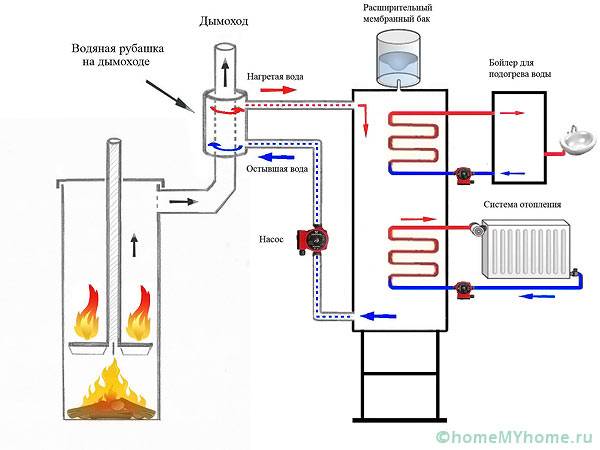

Gas generating or pyrolysis boilers for long burning with a water circuit are boilers that themselves generate combustible gases from the fuel that is placed in them. The water circuit is at the same time part of the heating system and the boiler safety system.

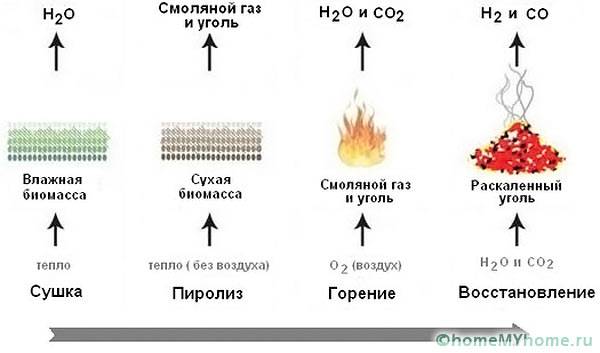

Pyrolysis as a physicochemical process

Combustion is a complex process that produces a lot of soot and gases. 30% of the total volume of emitted substances is carbon dioxide, the rest is carbon monoxide, nitrogen oxide, methyl alcohol, furan, acetic acid, benzene, acetone and a huge amount of other volatile substances. Everything except CO2, can be further oxidized, that is, burned again, while receiving some more heat energy.

Pyrolysis is a two-stage process in which the production of fuel gases is first stimulated and then burned. To do this, the solid fuel is set on fire and allowed to work, then the oxygen supply is reduced, stimulating smoldering. Firewood smolders at temperatures of 200 - 800 degrees, coal and hydrocarbon materials smolder at temperatures up to 1300 - 1500 degrees. At the same time, gases are actively evolved, which under atmospheric conditions are little active or inert.

In the combustion chamber inside the boiler, temperatures are extremely high, these gases react with oxygen supplied from the outside.At first, atmospheric air passes through special air ducts, warms up to the temperatures described above, and only after that it is mixed with fuel gases. Intensive afterburning of the gas mixture takes place. Outwardly, it looks like the combustion of natural gas supplied under high pressure, a powerful stable torch is formed. The heat generated is 4 to 10% of the total heat produced by the boiler.

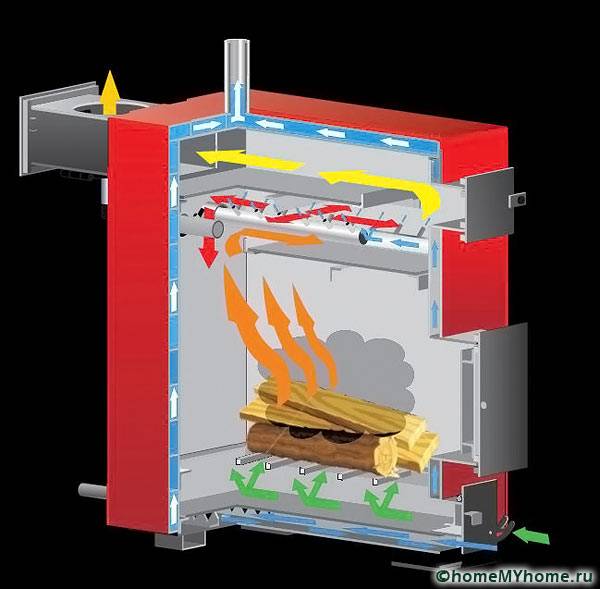

How the boiler works

Long-burning pyrolysis or gas-generating boilers with a water circuit are a chamber equipped with special partitions and air ducts. The special design of the blower allows you to regulate the amount of oxygen supplied. In the upper part of the boiler, where the afterburning takes place, there are nozzles that divide the gas into small streams in order to reduce the combustion intensity. The grate is located higher than usual, it is installed so that the distance to the bottom is not less than ¼ of the total boiler height. This is to ensure that there is sufficient space for the evacuation of gases.

Fresh air, necessary for additional oxidation, is supplied from below, passes through a special air duct up to the combustion zone of gases, while being heated to operating temperature. In the upper part of the boiler there are special tubes with holes that help to distribute gases evenly.

The entire circulation inside the boiler is provided by an electric turbine. Without it, under conditions of a lack of oxygen, combustion and additional oxidation are impossible. In the event of a power outage, it is necessary to open the gate to ensure natural draft, while the boiler continues to operate in the mode of a conventional solid fuel installation.

Video: pyrolysis boiler: myths and reality

Types of gas generating boilers

The principle of operation of all gas-fired boilers is the same, however, there are different design options:

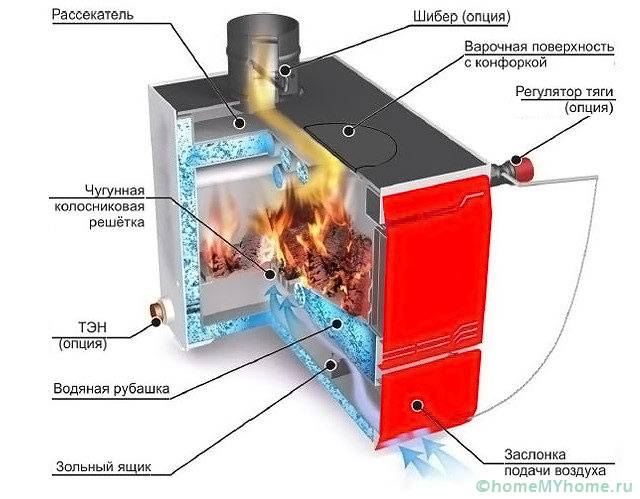

- A boiler with a water jacket - its body consists of two layers of metal, between which water flows.

- Coil boilers are devices with an ineffective heat exchange system; low-power devices are produced.

- Volatile and non-volatile boilers. The pyrolysis process is only possible with forced circulation. Non-volatile gas-generating boilers are a myth; without electricity, this device can only work in normal mode. solid fuel boiler.

Related article:

Wood burning boilers for home. From this publication you will learn everything about wood-burning boilers, their varieties and nuances of use.

Advantages and disadvantages

The principle of pyrolysis, which is partially implemented in domestic gas-fired boilers, is used in industry for the disposal of various waste. Combustion and repeated additional oxidation of decomposition products is a way to reduce the amount of harmful emissions into the atmosphere. After fuel and gases are burned out in a gas generator or in a domestic boiler, only carbon dioxide and water vapor are released into the atmosphere.

The environmental benefits of such boilers are obvious, but in terms of efficiency and convenience, they are seriously inferior to, for example, long-burning boilers. It is not easy to accelerate the boiler to such parameters that pyrolysis is possible. This requires a high temperature and some time. Long-term pyrolysis boilers with a water circuit are stopped under the following conditions:

- drop in return water temperature;

- power outage;

- fuel of inadequate quality.

The pyrolysis process must be stopped immediately as soon as the circulation pump in the heating system... Without cooling, the boiler will simply explode.To stop the process, you need to open the gate, ensuring natural draft and removal of combustible gases. The blower should be open to a minimum. After the temperature has dropped, the boiler should be extinguished. If the volume of the heating system is not large and natural circulation is possible, the boiler can continue to operate at 50% load with the gate open.

terms of Use

Pyrolysis boilers are capable of operating within a strictly defined temperature range. The system of this device is closed, therefore it must be precisely tuned. Obviously, it is not possible to constantly monitor the quality of fuel, its moisture content, and measure the mass of firewood at the time of loading. There is always a danger of overheating or, conversely, insufficient temperature.

The first problem can be eliminated with a water circuit. The boiler body acts as a heat exchanger: its walls are double, water circulates between them. Sometimes an additional coil is added to one of the boiler walls, which serves as an emergency cooling system and at the same time as a DHW circuit.

If the temperature is lower than the operating temperature, the pyrolysis process stops or does not start at all. At the same time, the boiler operates in the mode of a conventional solid fuel device. For this reason, the return temperature must be at least 60 degrees Celsius, and at 40 degrees, pyrolysis stops in all types of boilers. For this reason, an additional jumper is installed in the heating system - a bypass, which serves as a small circuit and allows the boiler to enter the pyrolysis mode.

It is necessary to install temperature sensors to control the process, but you will have to open and close the bypass valves manually. Pyrolysis boilers are generally manual boilers. According to the passport of the device, firewood, briquettes and pellets can be used in it. In real conditions, energy-intensive fuels such as coal are added to firewood. There is a practice of burning household waste, but it contains rubber and other polymers, which is fraught with unpleasant consequences.

Important! Burning coal, rubber and other energy-intensive fuels in boilers of low and medium power (up to 40 kW) is prohibited! Small size of the chamber, insufficient fan power, small volume of the coolant will lead to overheating and destruction of the boiler, which is accompanied by an explosion and fire! In high-power boilers, the proportions must be strictly observed: energy-intensive fuel should not exceed 20% of the total load.

When pyrolysis boilers are effective

The advantages of long-burning pyrolysis boilers with a water circuit are environmental friendliness. The efficiency declared by manufacturers is only 4 - 10% higher than the performance of a conventional solid fuel boiler. Obviously, the choice should be based on taking into account the individual characteristics of the heating system and the preferences of the owners.

Video: the principle of operation of the pyrolysis boiler DG "Trayan"