Combined boilers for heating with wood and electricity

AAutonomous heating is preferable from the point of view of saving resources and ease of use. The owners of houses equipped with boilers can independently decide when to start and end the heating season. The type of heater is selected depending on the type of energy to be used. Universal boilers for heating with wood and electricity allow at any time to use exactly the type of energy carrier that is available, as well as to make it possible to fine-tune the boiler.

The content of the article

Video: heating a private house with a combined boiler

Solid fuel boilers with electric heating elements

Solid fuel is not inferior in popularity to gas and electricity. In case of any cataclysms and accidents, such boilers can work and heat the home, and with the right heating system calculation and high-quality installation, solid fuel boilers are the most economical. The use of heating elements allows you to maintain the water temperature in the system at a comfortable level, even if the combustion process in the boiler is completed. Heating elements in all types of boilers are installed under the grate in the immediate vicinity of the combustion site.

Related article:

Electric boilers for heating a private house. In a separate publication, you will learn about the types, device and advantages of these types of boilers.

Wood fired boilers

To use firewood as fuel, the boiler must have characteristic features - front loading and a chamber depth of about 50 cm. The grate of such boilers is made of cast iron, below there is a blower and an ash chamber. The regulation of such a boiler takes place in manual or semi-automatic mode and is carried out as follows:

- a thermal sensor is installed in the heat exchanger inside the boiler, which registers the temperature of the water in the system;

- temperature data is transmitted to a thermometer located on the boiler body;

- in automatic mode or by manual adjustment, increase or decrease the supply of air to the combustion chamber.

Boilers used for all types of solid fuels

There are models of boilers that involve the use of not only firewood, but also other types of fuel - coal, pellets, peat. In this case, additional elements for loading and supplying fuel are added to the conventional design. When burning, firewood gives out a much lower temperature than coal, therefore, universal boilers have thicker walls.

Wood-fired boilers with the ability to connect a gas burner

Almost any boilers for heating with wood and electricity can be converted to gas. Many manufacturers initially include such an opportunity, supplying the kit to wood-fired boiler a suitable gas burner. Reverse alteration is also carried out without problems, just the panel with the built-in burner is replaced back with the door and the grate is replaced in its original place.

Boiler operation

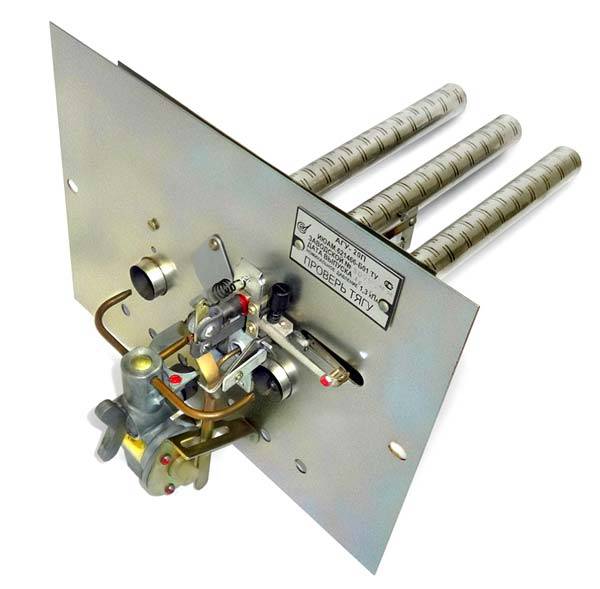

In general, a solid fuel boiler is a compact metal stove equipped with a combustion chamber, a heat exchanger, a smoke evacuation system and a door for regulating the air supply. The built-in electric heating element is located below the grate and is connected if necessary.

During the combustion of fuel, when the temperature of the water in the heat exchanger falls, the heating element heats it up until the solid fuel ignites again. This mode reduces the load on the heating circuits, and maintains constant circulation in open systems. Combustion of solid fuel is a process that does not lend itself to precise control and cannot be automatically stopped, therefore, the operation of such equipment should be stopped at night. The use of electric heating elements allows you to extinguish boilers at night, while maintaining the set temperature. Electric heating is not used as the main source of heat, since it is not profitable in combined-type boilers; for these purposes, there are other types of equipment.

Water circulation principles

The boiler for heating with wood and electricity heats the water in the system at the moment it passes through the heat exchanger. Heating occurs in three ways:

- water circulates through pipes inside the boiler;

- water circulates through the "water jacket" - washes the boiler outside;

- combined systems using external and internal heat exchange.

When choosing a boiler, preference should be given to those models in which there is the largest number of internal pipes, the efficiency of such boilers is always higher. An important parameter is the diameter of the entrance pipes return pipe must be greater than or equal to the outlet pipe, this configuration also increases the circulation efficiency.

Smoke evacuation

The removal of combustion products from a solid fuel boiler with electric heating elements should be carried out according to general rules using metal chimney pipe... The draft efficiency is not affected by which output is present on the boiler - back or top. More expensive models have a special device that equalizes the rate of gas removal. It is a set of special dampers that the smoke bends around when moving upward, while the heat remains inside the boiler and its efficiency increases.

Recommendations when choosing a boiler

Boilers for individual heating on wood and electricity are selected taking into account the following factors:

- the type of fuel available;

- data of a heat engineering calculation performed individually for a specific object;

- engineering features of the heating system as a whole.

It is possible to draw conclusions about the boiler power only if the above data are available, since the averaged recommendations are not always suitable for the operating conditions at a particular facility. Solid fuel household boilers with the ability to connect to electricity have a wide power range - from 6 kW to 100 kW, their cost varies from one and a half tens to several hundred thousand rubles.

Related article:

Solid fuel boilers for heating a private house. From this publication you will learn about the advantages of such units and the prices of popular models.

Solid fuel boilers can only be used if there is constant circulation, that is, either the heating system is built on the principle of natural circulation, or the circulation pumps are connected to an uninterruptible power supply. This is necessary because the burning of firewood cannot be stopped automatically and instantly, and if the pumps are stopped while burning continues, the water will boil, and the heating system will be seriously damaged.

Extra options

Important nuances to be aware of:

- boilers must be used for their intended purpose, that is, coal must not be used in appliances intended for burning wood;

- it is better to mount the gate at the chimney, although it is rarely used in combined boilers;

- the combustion regulator is not the most significant detail, as well as complex automation systems, since the adjustment task can easily be handled independently using the blower door;

- a water temperature sensor with a thermometer brought out to the case must be mandatory, otherwise you can miss the boiling point and allow an accident.