Gas floor boilers for home heating: selection and installation

ANDThe use of network gas can significantly reduce heating costs. After all, the cost of this resource is noticeably lower than the price of electricity, coal, firewood, diesel fuel or fuel oil. Floor standing gas boilers for home heating do not have the same power and service life limitations that exist for wall-mounted boilers. Of all types of gas boilers, floor-standing devices have the maximum ratio of service life, cost and efficiency, due to which in many cases they turn out to be preferable to wall-mounted ones, despite even more stringent requirements for the base and chimney.

The content of the article

Video: floor standing device selection

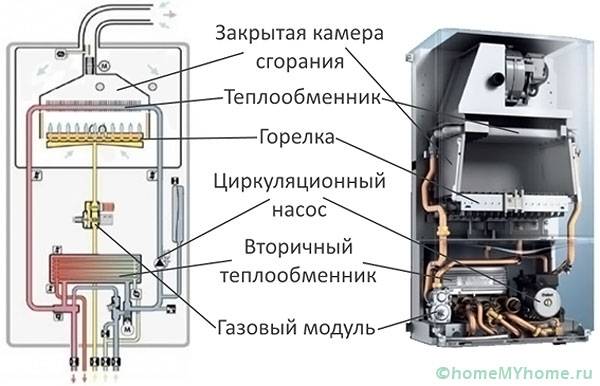

How are gas boilers

There are different types of floor standing gas boilers... They differ in:

- heat exchanger material;

- power;

- the presence of a second circuit;

- method of heat extraction.

Heat exchanger material

During the combustion of gas, a lot of heat is released, which passes through a heat exchanger of complex shape and heats the water. In wall-mounted appliances, this unit is made of steel or silumin, which is why the service life is short. This choice of materials is due to restrictions on the mass of wall-mounted boilers. There is no such limitation in floor-standing devices, therefore the heat exchanger is made of cast iron, which ensures a long (tens of years) service life and high efficiency.

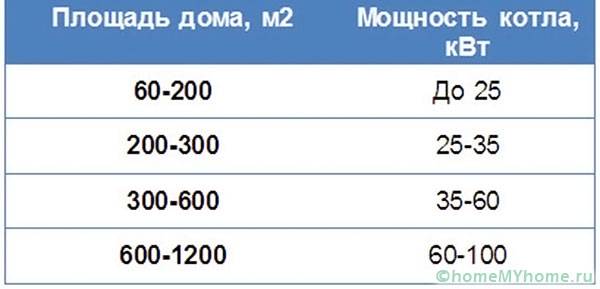

Power

Floor gas boilers for heating a house are produced with a capacity of 5 kW. This power is sufficient for heating a medium-sized house with an area of 50 square meters or a well-insulated house with an area of up to 70 square meters. The maximum boiler output is limited only by the area of the house and the bearing capacity of the base. There are models with a capacity of over 250 kW.

Second circuit

Floor standing gas double-circuit boilers for home heating not only effectively heat rooms, but also provide hot water supply. The use of a double-circuit device allows you to abandon any other water heaters... The second circuit does not affect the heating efficiency in any way and slightly increases the gas consumption. Such boilers can be used even in summer - the heating circuit heats up slightly, and the valve prevents circulation of water through the heating system.

Heat extraction method

The demand for units with minimal gas consumption has led to the emergence of condensing floor units. Floor standing gas condensing boiler for heating a private house differs from the usual one in that an additional heat exchanger is installed in it. This heat exchanger reduces the temperature of the flue gases to 55 degrees. This reduces gas consumption, but limits the temperature of the heating medium and negatively affects the condition of the chimney.

Related article:

Installation requirements for floor standing devices

The installation of floor-standing appliances implies the fulfillment of certain requirements, without which the controlling organization will not authorize commissioning. Here is a list of the basic requirements:

- the presence of a powerful concrete base;

- the presence of a ventilation duct;

- the presence of a capital chimney;

- separate room.

Concrete base

The weight of a floor-standing unit often exceeds 200 kilograms, which makes it impossible to install it on a wooden floor. Therefore, you have to cut out a piece of the floor, pour the foundation, then pour the concrete base. It is permissible to lay out the base of stone or bricks on cement mortar.

Ventilation duct

During the operation of the device, there is a possibility of a drop in draft and ingress of combustion products into the room where it is installed. Cravings can disappear for various reasons, such as:

- chimney clogging;

- strong gust of wind;

- insufficient air flow from the street.

If this happens, the ventilation (exhaust) duct must remove the combustion products from the room. To do this, its size is calculated in such a way that it can provide a complete replacement of air in the room in 20 minutes.

Insulated chimney

Unlike wall-mounted boilers, in which draft is generated by forced air supply, floor-standing units use natural draft based on different densities of cold and hot air. Therefore, for boilers of this type, an insulated chimney is required, otherwise interruptions in draft are not excluded when the air temperature drops to negative values. Such chimneys are most often laid in the walls of the house, thereby increasing the overall heat output. If the chimney runs along the outside of the house, then it is made of tin and insulation.

Related article:

Chimneys for a gas boiler in a private house. Selection rules and requirements for the installation of chimneys, their varieties and installation nuances in a special publication.

Separate room

Floor standing boilers must be installed in separate, adapted rooms. This is done to increase safety - if the draft is lost, then the ventilation duct will prevent the spread of carbon monoxide. After all, even a small dose of carbon monoxide leads to dizziness and loss of consciousness, and strong concentration kills a person.

Gas units and various types of heating

Floor standing gas boilers work effectively with any hot water heating systems... In a properly sized and installed natural circulation heating system, the devices operate without overheating, ensuring efficient movement of water. In systems with forced circulation, boilers do not affect the movement of water.Therefore, they can be installed both together with other heating devices and individually. No alteration of batteries or water floor heating is required.

How to choose a boiler

Best outdoor gas boiler for home heating can be selected according to the following criteria:

- matching power;

- reasonable price;

- reviews about a specific model and manufacturer.

When choosing a gas unit, you must first focus on power. A small power reserve will not hurt, but it makes no sense to buy a boiler twice as powerful as necessary. It will work in a non-optimal mode, which will increase the gas consumption and reduce the service life of the boiler. For many, the cost of the device is a decisive argument, especially since inexpensive models are often in no way inferior in terms of basic functions to units that cost 2-3 times more. To determine the reliability of a particular boiler, it is necessary to carefully consider the reviews of the owners of similar devices. This can be done in various forums where they discuss their experience of operating or repairing them. The video below will help you choose the right device.

Video: connecting a gas boiler