Design and installation of sandwich pipes for chimneys without mistakes and unnecessary difficulties

Various factors are used when choosing materials for this construction. In most cases, cost matters. But for correct conclusions, it is necessary to supplement the primary investment with expenses in the process of using the system, mandatory routine maintenance, and repair work. If it is planned to carry out the work on its own, pay attention to the realistic implementation of the project without the help of professionals. After a comprehensive assessment, it should be noted that sandwich pipes for furnaces have attractive parameters. After studying this article, it will be easier to confirm or deny the validity of such a statement, taking into account personal preferences and capabilities.

It is not difficult to create an efficient and durable smoke extraction system from such components.

The content of the article

- 1 Purpose of pipes for furnaces, formulation of requirements for a good system

- 2 Chimney sandwich pipes: modern engineering solution with advantageous parameters

- 3 Basics and important nuances of installing a chimney from sandwich pipes with your own hands

- 4 Prices for sandwich pipes for chimneys, the right choice of products

- 5 Video: stainless steel chimney sandwich pipe

- 6 Conclusion, additional recommendations

Purpose of pipes for furnaces, formulation of requirements for a good system

This information must be taken into account for the correct preparation of the technical task before the implementation of the corresponding project:

- The chimney for the oven must be exactly matched to the specific fume extraction capacity. It provides not only traction, but also the absence of carbon monoxide in the room.

- This structure gets very hot at the bottom. The temperature difference provokes the formation of moisture droplets on the inner walls. When mixed with soot particles, an aggressive chemical environment is formed.It has a devastating effect on various materials.

- Heating of the outer walls should not be dangerous for other elements of the building structure. Particular attention should be paid to the passage of the chimney route through the walls, floors, roof.

- At high heights, the pipe can be quite heavy. Excessive influence of its weight on the power frame of the house should be excluded.

Separately, you need to study the installation process. Some construction technologies are accompanied by significant difficulties for an unprepared person. For high-quality brickwork, for example, you need the appropriate skills.

Chimney sandwich pipes: modern engineering solution with advantageous parameters

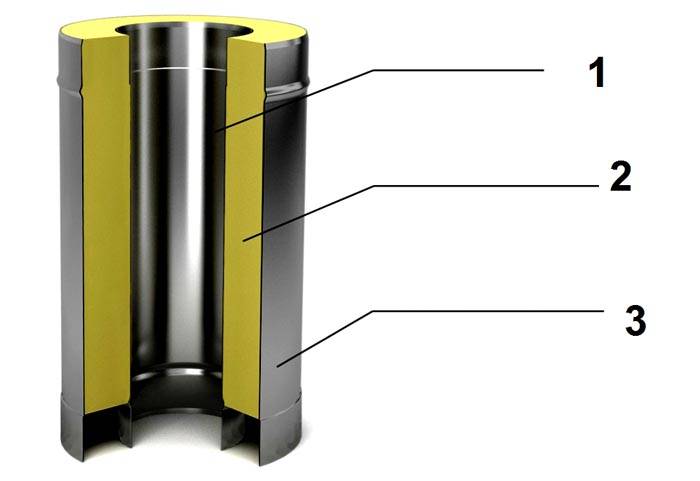

A typical product in this category consists of the following components:

- Inner sleeve made of steel (1). It provides structural strength, long-term preservation of its integrity when wetted, in contact with aggressive chemical compounds.

- The sandwich pipe for the furnace is insulated with non-combustible insulation (2). It is made of mineral wool, which is resistant to high temperatures.

- The outer sleeve (3) made of stainless or galvanized steel, just like the inner insert, acts as a load-bearing frame. It is well protected from natural influences. Two layers of metal prevent moisture penetration to the mineral insulation and extend its service life.

A detailed study of the sandwich chimney pipe allows us to note several positive points:

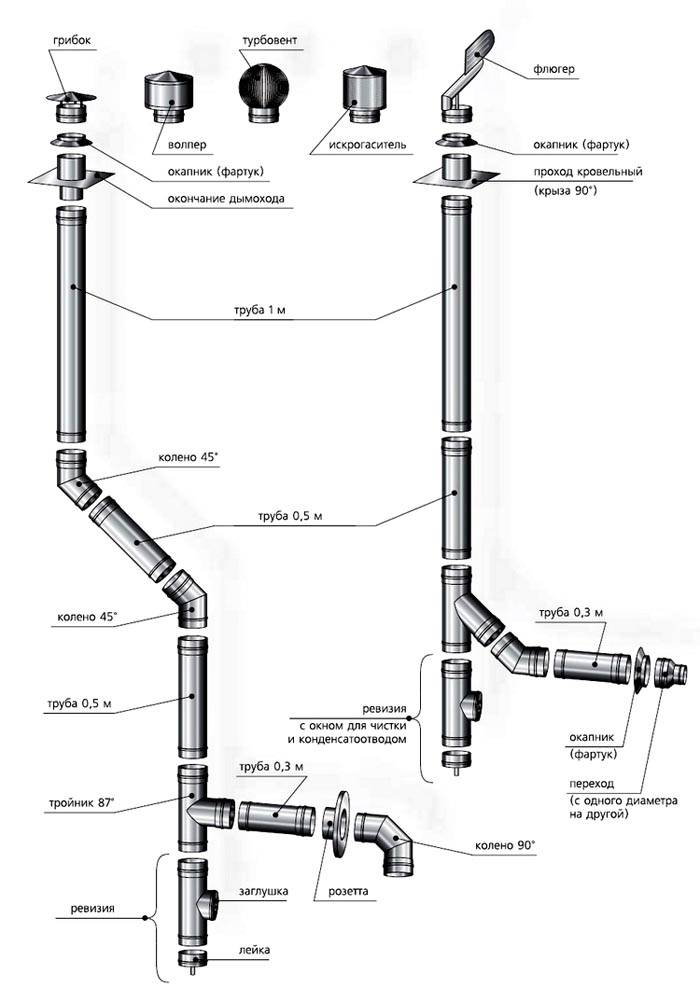

- Simple project preparation. It is not difficult to create an effective device for removing combustion products of any complexity from typical parts. As a rule, sellers offer free design documentation preparation services. They are carried out on the basis of standard developments using specialized software.

- Fast execution of installation operations due to the unification of hotel elements, exact size matching. Assembly technologies are thought out to the smallest detail. They are not difficult to learn and master using written and video instructions.

- Reasonable cost in comparison with structures of similar technical parameters from bricks... For an accurate analysis, you should consider the cost of all consumables, transport and installation operations.

- Even a tall sandwich oven tube weighs a little. There is no need to build a powerful foundation under it. It is quite enough to attach to the walls, elements of the structural frame of the structure.

- The smooth inner walls of such a chimney provide good draft performance. They do not prevent moisture droplets from moving downward. There you can install a special container for the accumulation and subsequent disposal of waste.

- The inner walls of high-quality chimneys and chimneys are made of special types of steel that are resistant to acids.

The flue gas temperature depends on the following parameters:

| Type of boiler, fuel | Temperature range, ° C |

|---|---|

| Pellet | 125-255 |

| Gas | 120-210 |

| Diesel fuel | 145-250 |

| Pyrolysis | 150-260 |

| Coal | 480-700 |

| Wood-burning stove in the bath | 450-750 |

| Fireplace | 350-600 |

It should also be noted that with constant heating during the day, dry wood can ignite at temperatures from + 170 ° C to + 180 ° C. The given data must be taken into account when planning the chimney path.... Potentially dangerous places are additionally protected. But this design, due to the internal insulating insert, does not conduct heat well.

Judging by the reviews, the chimney sandwich pipe can be installed even alone. The following materials will help you properly prepare for the successful implementation of such plans.

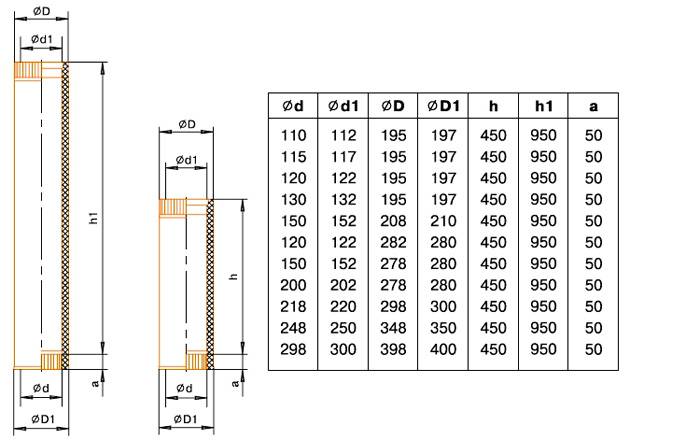

Dimensions and other specifications of fume extraction system components

To prevent the lower parts from being damaged by high temperatures, choose a suitable steel.Some modifications with additives of nickel, chromium and molybdenum are able to withstand prolonged exposure to temperatures up to + 800 ° C without damage. The corresponding products can be used in a set with any heating devices without restrictions. If you intend to install the system for pellet boiler, material requirements can be reduced with lower cost of component parts.

A typical assortment list of a profile manufacturer contains products with the following characteristics:

| Parameter | unit of measurement | Minimum / maximum value |

|---|---|---|

| Pipe length (height of straight lines) | cm | 50/100 |

| Inner diameter of sandwich pipe for chimney | mm | 80/130 |

| External diameter | mm | 195/430 |

| Thickness of metal sleeves | mm | 0,5/1 |

| Mineral wool layer thickness | mm | 40/60 |

For simplified calculations, you can use the following dependencies:

| Boiler power, kW | Minimum inner diameter, mm |

|---|---|

| Less than 3.5 | 80 |

| 3,5-5,5 | 90 |

| More than 5.5 | 110 |

In practice, they provide an exact match of dimensions, or an increased duct for the removal of exhaust gases. For example, a 115 mm diameter chimney sandwich pipe can be connected to a 110 mm boiler nozzle.

Calculator for calculating the minimum diameter of a sandwich chimney for solid fuel stoves

Related article:

Chimneys for a gas boiler in a private house. Selection rules and requirements for the installation of chimneys, their varieties and installation nuances in a special publication.

DIY chimney sandwich

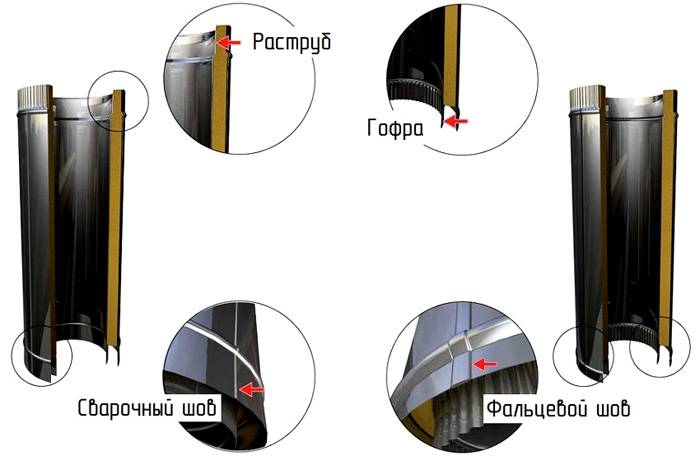

If necessary, the system components can be manufactured by yourself. The following algorithm will help you create a sandwich pipe for a chimney with your own hands:

- After calculation, taking into account the parameters of the boiler, the building and other important parameters, the required dimensions are set. The requirements for the grade of steel should be precisely defined so as not to damage the products by high temperatures.

- The inner tube is available in one piece. It is necessary to choose products with a straight longitudinal seam that does not impede the movement of smoke and condensation.

- A layer of mineral wool is wound on this base. You can not use ropes, cotton wool, other heaters that ignite at a relatively low temperature.

- A prefabricated steel box is fixed on top. To fix its components, bolts with nuts and other fasteners are used.

It is necessary to clarify the feasibility and possibility of independent production of high-quality pipes. To create a functional smoke removal system, you will need not only them, but also other elements.

Basics and important nuances of installing a chimney from sandwich pipes with your own hands

The following description will help you install the structure without assistance:

When installing a chimney in a sandwich pipe bath, a part of the overlap transition is created.Below, such a structure is installed, which takes useful heat from heated gases.

Thematic materials will help you learn how to install a chimney from a sandwich pipe. The video below clearly demonstrates the solution to the complex problem of connecting the system with heating boiler.

How to make the installation of a chimney from sandwich pipes through the roof without mistakes

It is necessary to remember the general recommendations that are used at the design stage:

- For good traction, it is necessary to minimize the length of the horizontal sections (length - no more than 100 cm), the number of turns.

- Installation of special nodes, windows for revisions, will simplify the inspection and cleaning of the system.

- The channel for the removal of combustion products should not be in contact with electrical networks (power supply, information), gas pipelines.

- When passing through the roof and other building structures, they create a layer of insulation that prevents excessive temperature effects on the structure.

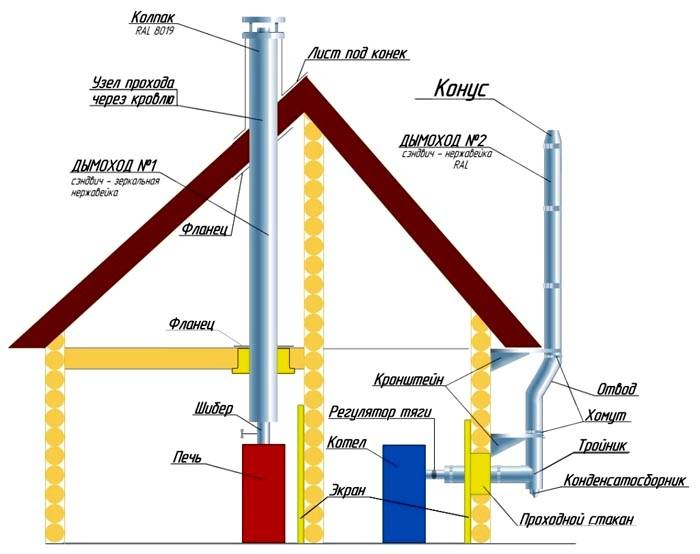

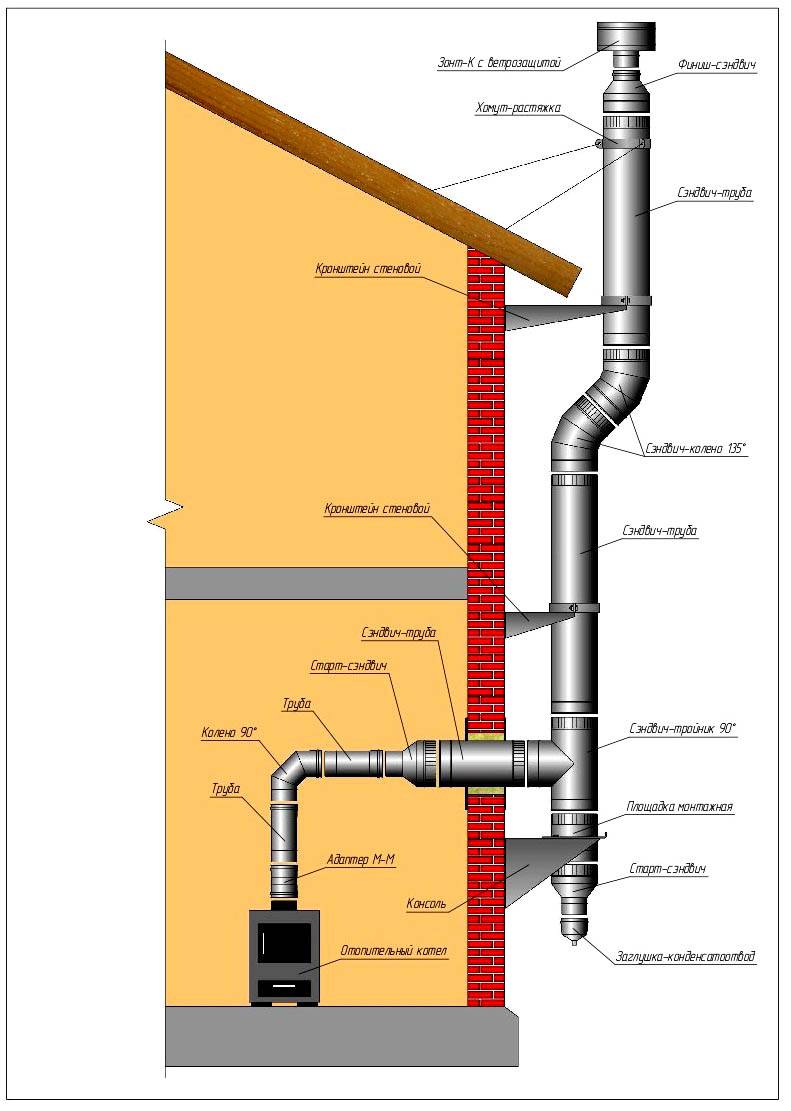

Using this picture, you can examine the structure of the chimney from the sandwich pipes through the roof. With a sufficient height at the place of this transition, the temperature of the outer walls will not be high. Natural cooling of this area should be noted. Here, more attention should be paid to the tightness of the joints, resistance to wind loads. To completely exclude contact with ceilings, the pipe is installed outside the building. But in this case, you will have to create a horizontal section that goes through the wall.

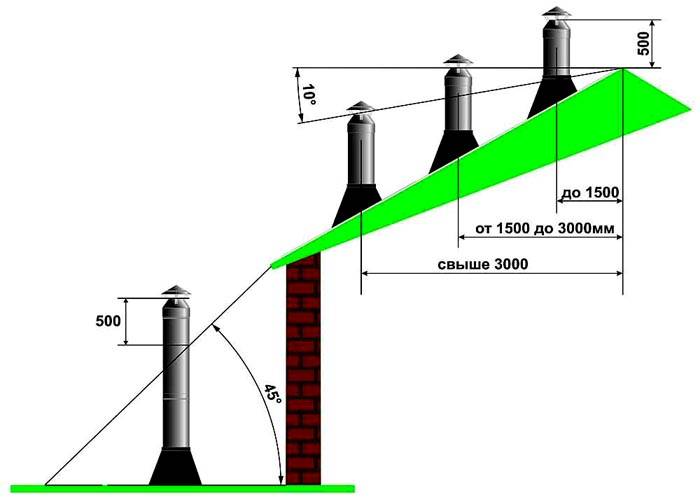

Note! The part of the chimney protruding above the roof should exceed the ridge by 50 cm, if the distance to it is 150 cm. When these elements are removed by three meters, the same level can be used.

In order not to complicate the installation, the pipe should be installed between the beams. It is better to remove it from the windows built into the roof. In the valley area, water accumulates, so it will be more difficult to create high-quality waterproofing here.

This special rubber sleeve and metal pad kit is used to seal the outlet assembly. Be aware of the corresponding deformations that occur when materials expand when exposed to high temperatures. The master flush prevents moisture penetration, but does not interfere with the movement of the pipe.

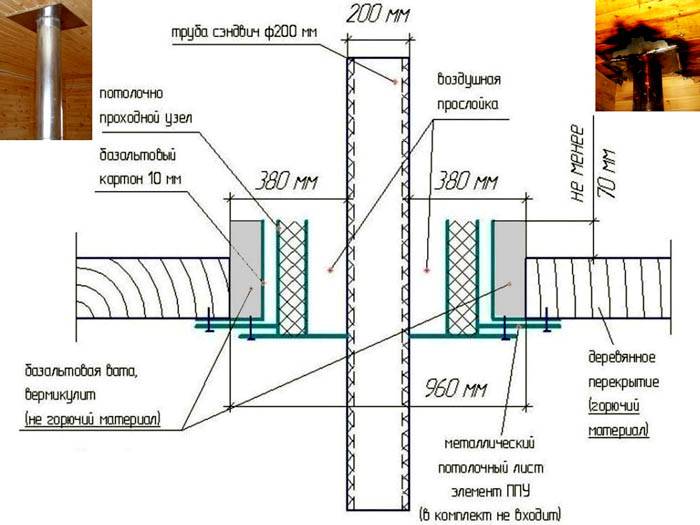

Features of the installation of structures when passing overlappings

When studying this unit, special attention must be paid to the distance from the chimney to parts of the structure. In accordance with the current regulations, it cannot be made less than 38 centimeters in any direction (passage through wooden floors). This value applies to the center sleeve. It is assumed that the free space will be filled with non-combustible materials. If wooden structures are protected from high temperatures, the distance may be reduced to 25 cm. Without insulation, the distance to combustible parts of the building structure must be 50 cm or more.

Here, the negative effect of high temperature blocks the sheet of metal. The polished surface reflects infrared radiation downward, which increases the efficiency of the heating system

Important! When designing a chimney from a sandwich pipe, the transition through the floors is made in one element, without joints.

The height of such a product should exceed the thickness of the overlap by 7 cm.

Wall mounting: helpful tips

This horizontal section of the route is made with a slight outward slope to prevent condensate drops from rolling into the boiler or other heating device.When passing through a wooden wall, the same restrictions apply as for slabs. This means that in order to reduce the hole, it will be necessary to insert a metal box, another protective element with insulation.In this unit, it is difficult to work with granular backfills, therefore, mineral wool is used.

Correct creation of a transition from a brick section of a chimney to a sandwich

It is installed on a brick end, which is leveled and cleaned of dirt. The transition from a brick chimney to a sandwich is not installed directly above the heating equipment. It is desirable that the abutting holes are equal in area.

Related article:

Chimney cap. A special publication of our online magazine provides recommendations on the choice of weather vane for different types of chimneys and some of the nuances of installation.

Prices for sandwich pipes for chimneys, the right choice of products

On the Internet, it is not difficult to find the official websites of specialized manufacturers. There you can get acquainted with the detailed technical characteristics of products, clarify other important nuances. Nowadays, you can buy a sandwich pipe for a chimney quickly and inexpensively, without intermediaries. When choosing, pay attention to the following information:

- The assortment should be sufficient to purchase all system components in one place. This will prevent assembly problems.

- The wall thickness and other general parameters are selected taking into account the requirements set out in the article. If you purchase a sandwich chimney pipe made of stainless steel, the price will be higher compared to galvanized sheet. But in the first option, you can count on long-term operation without problems.

- The cost of products is complemented by transport costs. Check the warranty obligations, payment terms.

- Additional benefits can be obtained when conducting marketing campaigns. Some businesses offer seasonal discounts.

This table will help you study the current state of the market:

| Pipe grade | Length, m | Material | Diameter (mm) / Wall thickness (mm) | price, rub. | |

|---|---|---|---|---|---|

| Inner tube | Shell | ||||

| Vesuvius | 1 | Stainless steel | 200/1 | 260/0,5 | 2800-3100 |

| "Dymoff" | 0,5 | Stainless steel | 180/1 | 260/0,5 | 1450-1600 |

| "Dymoff" | 0,5 | Zinc / stainless steel | 115/1 | 260/0,5 | 1600 |

For a complete analysis, it is necessary to check the cost of installing chimneys from sandwich pipes. When studying the relevant proposals, it is worth finding out not only the price for 1 running meter. Sometimes they pay additionally for the departure of the master for measuring, insulation and sealing, protective measures during the passage of building structures.

Video: withendwich chimney pipe stainless steel

Conclusion, additional recommendations

Sandwich pipes for chimneys are not expensive, so making them yourself is hardly advisable. A comparative analysis should take into account the cost of high-quality components, assembly, lack of guarantees. But the installation operations can be performed without assistance. To eliminate errors and additional costs, you need to carefully prepare the project.