Long burning wood stoves-fireplaces for summer cottages and not only

PChimney-fireplaces are good because they are autonomous heat sources. For Russian conditions, one such furnace is enough to heat more than 50 square meters of area. In many villages, similar stoves are still being built, because they allow, in the absence of gas and electricity, to effectively warm houses and even cook food. Long-burning wood-burning fireplaces for summer cottages are suitable precisely because they are autonomous and at the same time extremely effective.

The content of the article

Video: ideas for fireplace stoves for summer cottages

Types of long burning brick ovens

Long-term burning in brick ovens is achieved if there are two or more blowers at different heights. The gate is almost always closed, there is only a small gap for smoke evacuation, strong draft is unacceptable.

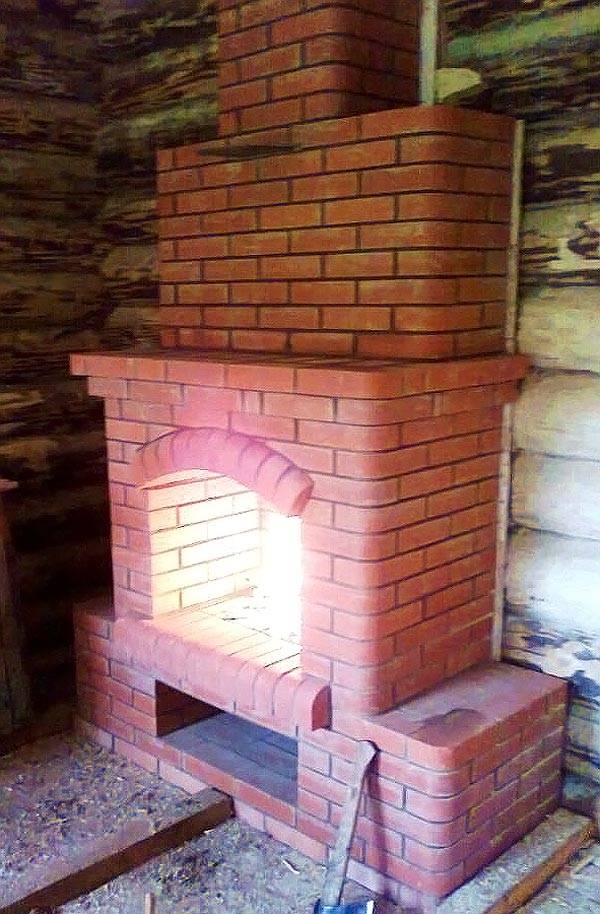

Fireplace stoves can be of two types - with and without a hob. In both cases, you can admire an open flame, while a sufficient level of fire safety is achieved, but in the first case, there is the possibility of cooking. The operational qualities of a stone stove directly depend on the experience and degree of responsibility of the master who builds it.

Related article:

Wood burning boilers for home. From this publication you will learn about everything about wood-burning boilers, their varieties and nuances of use.

Compact stove

This design is made of two types bricks - facing outside and heat-resistant inside. For the construction of the stove, only ceramic bricks of the highest quality of a brand not lower than M175 are used. A compact fireplace stove, laid out in compliance with all requirements, has the following characteristics:

- warms up evenly throughout the volume, the front part is 6 - 8 degrees warmer than the rest;

- smoke, sparks and soot do not fly out of the combustion chamber;

- the cooling process occurs gradually.

Compact long-burning wood-burning stoves for summer cottages are also suitable because they take up little space, fire safety standards allow the construction of structures with a side length of 51 cm.

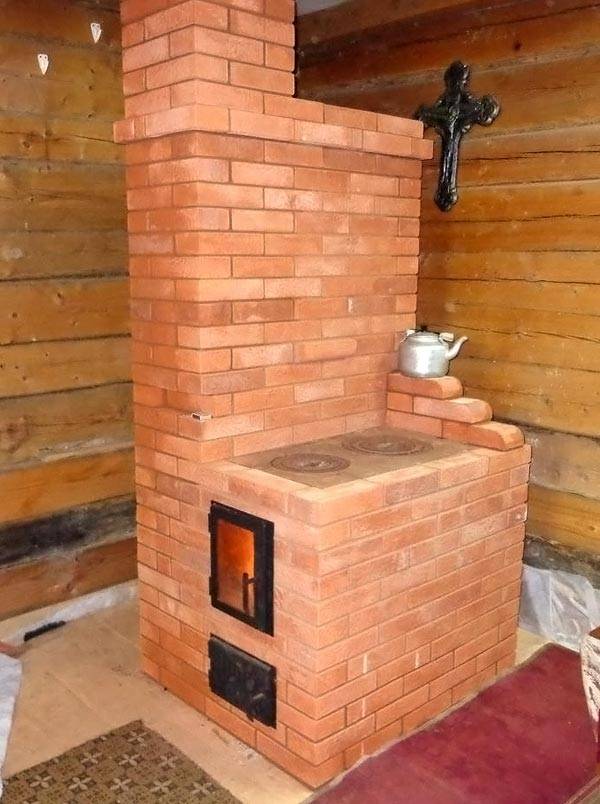

Fireplace stove with hob

Fireplace stoves with a hob are ideal for country houses, in which there is no possibility of connecting a gas or electric stove. They are also built from heat-resistant bricks, but additional cast iron elements will be required. Such a stove requires more fuel, for example, to heat a room with an area of 30 square meters, it takes about 8-10 kg of dry firewood at a time, versus 6-8 kg for a compact analogue.

Related article:

Wood-fired sauna stoves with water tank. Which oven to choose for your baths? Metal or brickwork? How to mount a water tank? More details in a separate review.

Brick oven technology

In order to ensure uniform long-term combustion, several conditions must be met: the presence of traction, that is, the supply of air and the removal of combustion products, as well as the ability to regulate the intensity of the air flow. If the principles of forming the internal chambers are not followed, the thrust will be so strong that all the heat will fly into the pipe or destroy the chimney ahead of time. With sloppy laying, smoke will pass through the cracks, which poisons the air and settles on furniture... You can avoid these problems if you strictly follow the instructions for installing the stove.

Stove construction

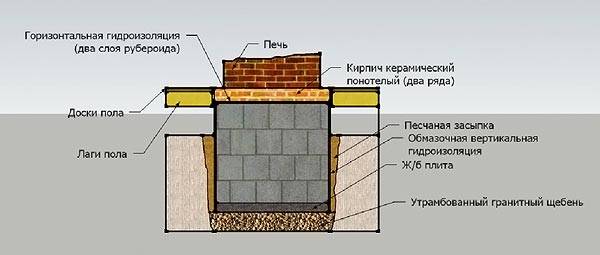

The first step is to lay the foundation. Since wood-burning stoves, long-burning fireplaces for summer cottages, are massive structures, they need a solid foundation with a depth of at least 50 cm below the zero mark. The length of the sides of the monolithic foundation must exceed the length of the sides of the furnace by at least 5 cm. After pouring, the concrete must gain sufficient strength, therefore, work on the construction of the furnace can be started no earlier than 25 days later.

The second stage is the preparation of materials and tools. It is always preferable to use clay as a binder in the construction of furnaces, since it is more plastic. Under the influence of constant temperature drops, it retains its properties longer than cement. Depending on the design of the future furnace, it is necessary to stock up on cast-iron elements - doors, grate, tilesas well as steel wire and corners.

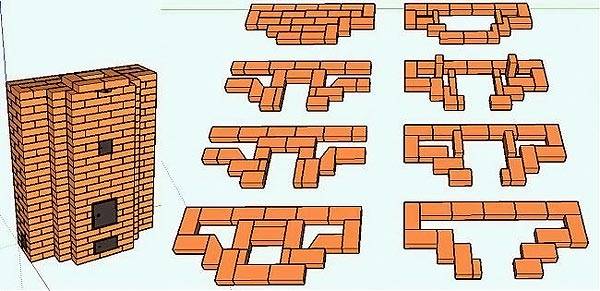

The third stage is a trial dry layout, which is performed according to a previously prepared order - a layout of bricks in each row. This action will allow you to assess in advance possible difficulties and avoid unnecessary waste of material and time.

Related article:

Standard brick: dimensions and characteristics. Which brick should you choose? What parameters does it have? About this and much more in a separate publication of our portal.

The fourth stage is the construction of a fireplace stove. In the process of work, the most important thing is accuracy, adherence to the integrity of the seams and proper installation. A lot, if not everything, depends on the skill of a bricklayer. Cast iron parts and glass door are installed along the way. Metal products are fastened using steel wire, which is fixed in the body of the masonry and serves as additional reinforcement.

Chimney installation

The chimney passes through the ceilings and the roofing cake, while it comes into contact with the combustible materials of which these structures are composed. In houses with stove heating, there is always a potential fire hazard from a chimney overheating. To avoid this, you need to follow the following specific rules.

When installing a brick chimney, carefully observe the vertical direction, avoid distortions.The joints between the bricks must be made with a particularly high quality so that sparks cannot jump out even with very strong traction.

When device metal chimney it is necessary to mount it in special double-circuit insulating sleeves that do not allow the contact of the glowing metal with roof elements and floors, while the weld seam of the steel pipe itself must be reliable.

Advantages of high efficiency furnaces

Brick wood stoves, long-burning fireplaces for summer cottages, differ from all other stoves in high efficiency, which is achieved due to very slow combustion of fuel. Firewood is loaded no more often than once a day, such a furnace is melted from above, while opening the upper door of the blower. As the wood burns out, the top door is closed and the bottom door is used.

Wood-burning stoves, long-burning fireplaces are used for giving not only in an economical mode, but also in a regular mode. To do this, open the gate and instead of the upper blower immediately open the lower one, thus increasing the thrust.

Comfort and safety

With prolonged burning, several problems are solved at once, the consumption of firewood is reduced, and the room is heated more evenly. With this operating mode, the chimney rarely heats up, the temperature of the combustion products does not exceed 300 degrees, which ensures a high level of fire safety. With a slow combustion in a lack of oxygen, the consumption of the latter also decreases, so it will be comfortable to stay in a room with a firing stove. How it is used for home heating oven with water circuit, read in a separate publication of our portal.

Video: laying a wood-burning fireplace