DIY furniture made of wood - is it so difficult?

The design of any room involves not only selection decoration materials for walls and floor, but also the arrangement of furniture. The latter largely determines how comfortable and convenient it will be to use a particular room. It is not always possible to immediately purchase a ready-made version, and custom-made production can be quite a costly event. In such a situation, it is best to make furniture with your own hands from wood, choosing a suitable solution for the configuration and design.

The content of the article

- 1 Furniture materials: our advice will help you make the right choice

- 2 DIY furniture: drawings and diagrams for the manufacture of a durable and beautiful product

- 2.1 No idea? We study the photo of wood furniture with our own hands

- 2.1.1 We make garden furniture from wood with our own hands

- 2.1.2 Video: DIY wooden garden furniture

- 2.1.3 Options for making children's furniture from wood

- 2.1.4 DIY options for making furniture for a gazebo made of wood

- 2.1.5 Options for making do-it-yourself furniture for a summer cottage made of wood

- 2.1.6 Options for making do-it-yourself furniture in a wooden bath

- 2.1.7 Options for making kitchen furniture

- 2.1 No idea? We study the photo of wood furniture with our own hands

- 3 DIY wood furniture restoration: the procedure is curled from defects

Furniture materials: our advice will help you make the right choice

The choice in favor of wood is made due to the advantages of this natural material:

- Durability. If the production technology is observed and a protective layer is formed, a long service life of products made from solid wood can be guaranteed. Adhering to certain recommendations for the care of a wooden surface, you can use table or chairs for half a century;

- Presentability. Products create a special atmosphere, becoming the center of attention of others;

- Naturalness;

- Ergonomics. When developing furniture sets, the characteristics of specific people are taken into account;

- Maintainability;

- Choice of finishes;

- Uniqueness. No one else will have exactly the same furniture.

The manufacture of furniture from wood is most often performed from wood panels, which can be:

- Solid, made of solid wood;

- Glued or compressed. In the production of such panels, thin wooden sheets are reliably connected to each other, forming an integral material.

Attention! Shields are irreplaceable in the manufacture of cabinet furniture for the kitchen, hall, nursery, tables.

For making furniture with your own hands from furniture boards, you can use material of different colors. In the catalogs of manufacturers there is wood in light and dark colors. This will allow you to choose the right option for a specific interior.

If the cost of ready-made panels seems too high, you can make furniture with your own hands from available tools. In this case, you will have to show a certain imagination so that the found branch, snag, branch or pallets left after building materials become part of the future product.

In an effort to reduce the final cost of the product, some make furniture with their own hands from Chipboard... In a certain situation, this option deserves attention, but you should not count on a long service life of a ready-made headset or table. This is an economy option that is suitable for country house... It is not worth moving such products from one place to another.

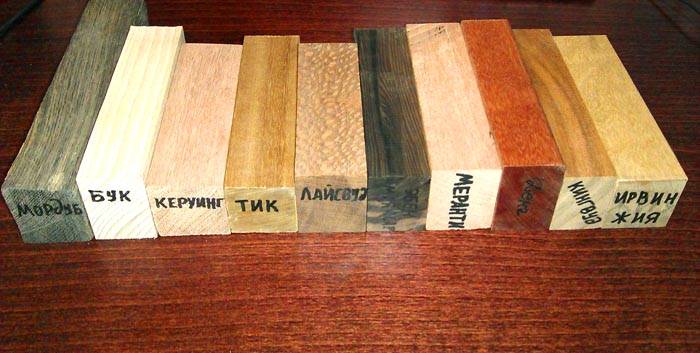

To make furniture from solid wood with your own hands, wood of various species can be used. It should be borne in mind that it can be:

- Solid. Suitable for the manufacture of load-bearing elements. It can be apple, beech, oak, sycamore, elm and many others. Elements made of such wood are capable of withstanding a significant operational load;

- Soft. A suitable option for the manufacture of elements of decoration or ornament. Using cedar, poplar, birch, pine, willow or alder, you can get a product with a fairly beautiful texture. Due to its plasticity, the product lends itself well to processing, allowing you to form an element of the desired shape and size.

When choosing a wood species, you should also focus on the texture and texture of the material. A smooth countertop can be obtained from beech, linden or birch. When using walnut, blanched pine, oak or ash, some relief can be achieved.

When deciding to use an array, you should make sure in advance of the quality of the material. It should be:

- Practically free of knots, which significantly reduce the strength characteristics of wood;

- With a snug fit for the annual rings. This is especially true for the coniferous massif. The closer the rings are, the stronger the board will be;

- No fungus. Its presence is evidenced by the uneven color of the wood. Especially in places of cut.

Advice! If it is decided to use wood of different species for the manufacture of furniture, you should choose a material with a similar structure in order to eliminate uneven drying.

Features of the manufacture of wooden furniture

Before starting the production of wood furniture, you should prepare the necessary tools, equipment and materials. It is worth taking care of the availability of a woodworking machine that allows you to form a surface of any shape and size. This will allow you to implement any project you have planned.

The manufacturing process itself includes the following steps:

- Project development. It is important to consider where and how the future product will be used, its size and shape. Drawings of all elements for the future product are being worked out in detail.

- Markup. At this stage, drawings from paper or electronic media are transferred to wood.

- Sawing. All elements are cut to size.

- Processing with special compounds, the characteristics of which depend on the place of future operation. It is desirable, in addition to biosecurity, to provide protection against moisture.

- Decorative coating. It can be varnish or paint.

- Assembly. The connection of the elements can be done using adhesives, laths, dowels. Other technology may be used.

DIY furniture: drawings and diagrams for the manufacture of a durable and beautiful product

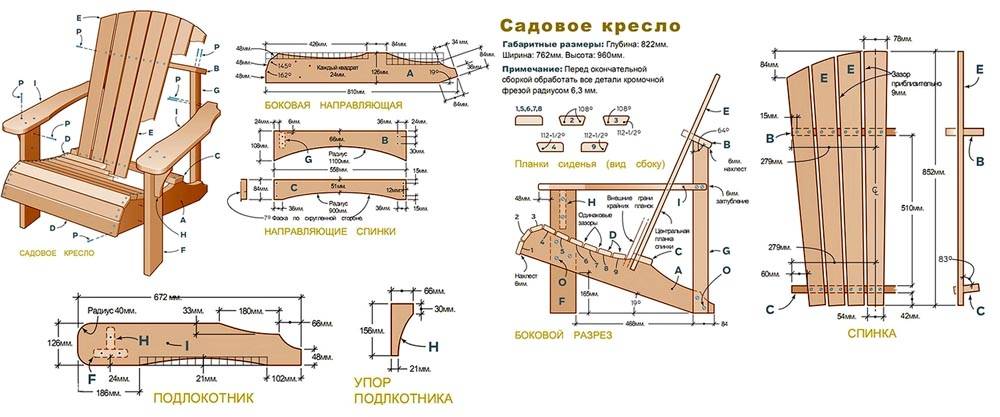

To make furniture with your own hands at home, you will need a drawing. You can develop it yourself or look for a ready-made solution among the documents that are in the public domain. The first option is preferable, as it allows you to make a unique product adapted to the needs of a particular family and the conditions of future use.

DIY furniture making can be done in different ways. It all depends on the material used and the method of connecting the individual elements. The dimensions and configuration of products are directly dependent on the place of their installation. The operating conditions also determine the type of finish used and the required level of protection from external factors.

Many people find interesting ideas for making furniture with their own hands on specialized forums and in social networking groups. Beautiful pictures are often accompanied by a detailed master class, which is easy to adapt for the production of a product of the desired shape and size.

No idea? We study the photo of wood furniture with our own hands

It can be quite difficult to start making furniture with your own hands from wood. Especially in the absence of a sample. In this case, it is worth looking for an analogue that will be easy to adapt for certain operating conditions.

When deciding how to make wood furniture with your own hands, you should decide on the place of its installation. The garden will require one bench, which is not at all suitable for a children's room or kitchen.

Note! By paying attention to detail, you can get a beautiful piece that can last a long time.

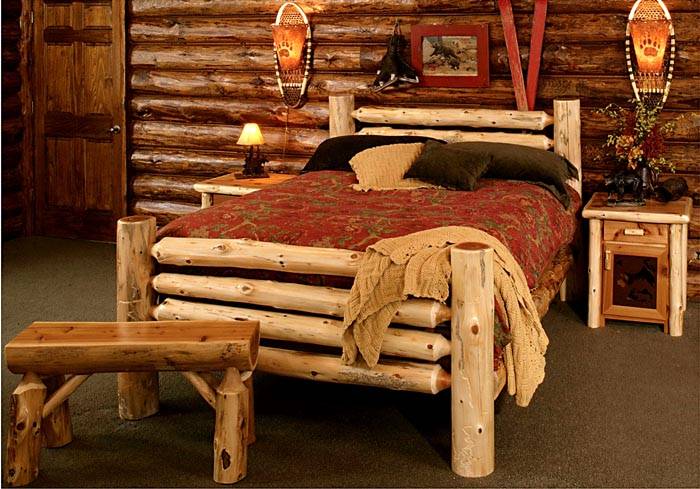

We make garden furniture from wood with our own hands

It is customary to use inexpensive furniture for arranging a country house and the surrounding area. If desired, it can even be made from scrap materials. It can be palletsthat are large enough.

Such products usually remain after building materials, such as blocks, and can become a suitable blank for a table or sofa. Pallets are often sold in specialized stores. Their cost is much lower than the cost of solid wood, and therefore such a purchase can be safely called profitable.

The surface of the pallets is not continuous. They consist of boards nailed to the frame with a pitch equal to half the width of the board. The height of the side can vary from 10 to 14.5 cm. The size of the pallets may vary. Dimensions depend on the place of manufacture. The European standard prescribes the use of pallets with dimensions 0.8 x 1.2 m. Very often a solid board is mounted. Domestic counterparts are slightly wider: 1 by 1.2 m.

Pallets should be processed before assembling the furniture. To do this, after removing all dirt, the product is dried and sanded.

Advice! In order not to accidentally drive a splinter during the operation of the finished product, all pallet boards should be coated with a paint and varnish composition. This is usually done after assembly.

If you decide to give preference to the massif, it is worth choosing a solid rock.For the manufacture of supports, it is better to use rounded pine. The rest of the surfaces can be formed using boards. The finished product will certainly last long enough.

According to the drawings, do-it-yourself garden furniture made of wood is made taking into account the peculiarities landscape design... Attention should be paid to the configuration of future products. They must harmoniously blend into the surrounding space.

To increase the service life of garden furniture made of wood with your own hands, all elements should be treated with special compounds. An antiseptic will prevent wood from rotting and abrasion in the event of mechanical stress.

Advice! For comfortable operation of a chair or bench, the seat should be fixed with a slight slope towards the back.

Related article:

In our review, we will find out how DIY garden bench with backrest... Drawings and detailed photos will allow you to make the best design.

Video: DIY wooden garden furniture

Options for making children's furniture from wood

The products that are planned to be installed in the children's room are subject to increased safety requirements. They also need to look pretty to grab the baby's attention. As a rule, do-it-yourself children's furniture made of wood is made from solid wood. This allows you to get a quality product with excellent technical characteristics.

There are always many dolls in the girl's room. To accommodate them, you can make a unique house, which will undoubtedly become one of the main interior decorations.

DIY options for making furniture for a gazebo made of wood

By using solid wood to make a table and benches, you can create a beautiful set of furniture for gazebos.

If the square of the structure is relatively small, and you want to dispose of it wisely, you should pay attention to folding products. When assembled, they take up little space. When unfolded, they allow you to comfortably stay.

Bench configuration and color may vary.

Options for making do-it-yourself furniture for a summer cottage made of wood

It is not difficult to make a country house cozy. It is not necessary to purchase new material for this. Wooden boxes can be used. By purchasing accessories, you can make a stylish coffee table.

To have a place to sit, it is worth making upholstered furniture. The frame of the sofa should be sawn out of solid wood to withstand the load.

Making country furniture from wood with your own hands from a photo, you should pay attention to the possibility of choosing upholstery and finishes. In this case, the finished chair can become a serious competitor to expensive products from elite manufacturers.

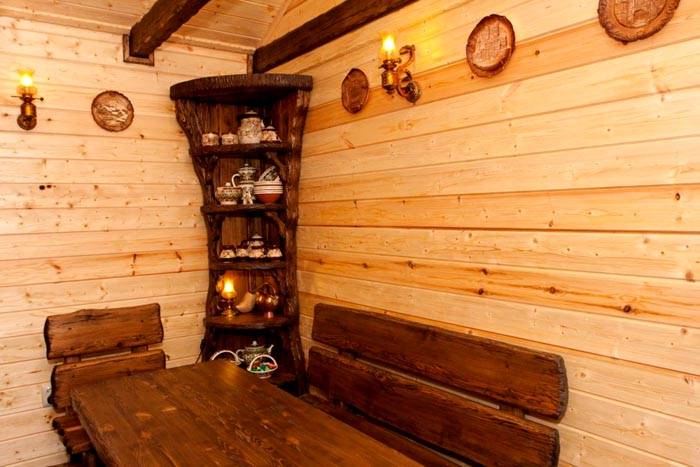

Options for making do-it-yourself furniture in a wooden bath

Given the special operating conditions, it is better to use hard wood for the manufacture of such products. You should immediately abandon coniferous varieties, as resin may appear on the surface of the finished product during operation.

For storing things in the dressing room, you can make a bench with drawers. The standard height will be enough to accommodate most bath accessories.

After the bath, many gather in rest room... Having made a bench, a table and hinged shelf, you can relax comfortably after bath procedures.

Advice! Apply a special protective compound to slow down the decay process in conditions of high humidity and significant temperature fluctuations.

Options for making kitchen furniture

A kitchen set must have a number of properties. On the one hand, it should be beautiful, on the other, functional. For those who do not like ornament and sophistication, you should definitely make kitchen furniture out of wood with your own hands without any finishing. Such a set will look appropriate in a private or country house.

If this option seems too simple, you can transform the headset by decorating a wooden kitchen facade with carvings with your own hands. What pattern will be formed is not important in this case. In any case, the finished product will turn out beautiful and non-standard.

If room area is limited, it is worth considering the option of making a desktop with a special niche for the table at which the family will have dinner.

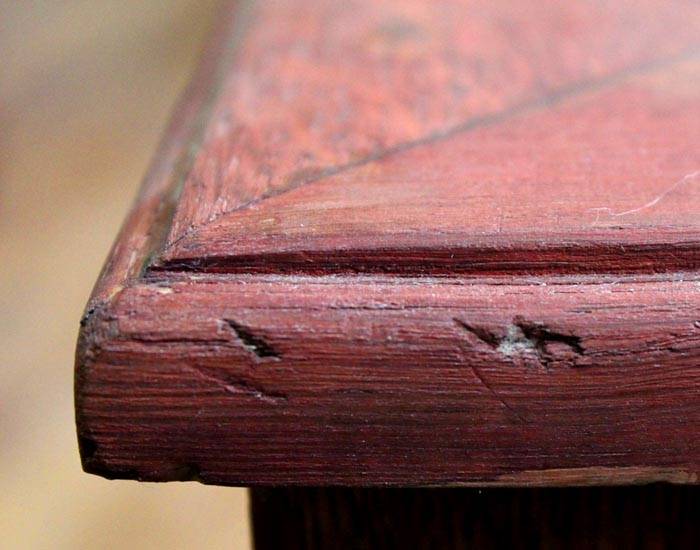

DIY wood furniture restoration: the procedure is curled from defects

No matter how carefully the owners treat their furniture during operation, minor mechanical damage will surely appear on its surface, impairing the appearance of the product. If the strength characteristics of the product are not lost, everyone will think about how to update wood furniture with their own hands. The procedure will depend on the nature and depth of the defects that appear.

We remove scuffs and shallow scratches

Small defects can be removed using special touch-up markers and pencils. These items are sold in specialized stores and come in a variety of colors. For the restoration of a certain surface, it is worth choosing a product that is close in tone.

Manufacturers offer:

- Retouching markers, consisting of opaque quick-drying enamel in different shades. Such compositions are not afraid of the effects of detergents and allows you to do without applying a protective layer of varnish. If the desired shade is not commercially available, the desired color can be obtained by applying several layers of marker;

- Alcohol based retouching pencils. Leaves the wood texture visible. Does not harm the base. The base of the pencil is an alcohol stain. To increase the durability of the formed coating, the restored surface should be covered with a layer of protective varnish;

- Retouching texture pencils. Created specifically for drawing wood texture. Thin rods allow you to repeat the contours of any defect, including those located in a hard-to-reach place. After application, rub with wax or cover with a layer of varnish.

Get rid of deep scratches and chips

Deep scratches tend to be long. If you use a special wax, the damage will be almost invisible. Manufacturers offer various formulations that differ in color and hardness. When using a transparent composition, a subsequent application of a layer of enamel or tinting varnish is required.

Advice! Before applying wax to the surface to be reconstructed, the composition should be thoroughly warmed up, and then rubbed in, making smooth movements.

To hide more chips and dents you will need wood putty... You should choose a composition close to the base color. The putty is applied in several layers, after waiting for the previous composition to dry completely. After removing the defect, use fine sandpaper to level the bases. After that, an additional layer of varnish is applied.

Removing stains

Gasoline will certainly help to get rid of traces of obscure origin on a polished base. This requires:

- Moisten a rag with gasoline;

- Wipe the stain;

- Repeat if after drying, contamination is present;

- Wipe the base with a rag;

- Restore the damaged polish with denatured alcohol or linseed oil.

Attention! Vodka or rubbing alcohol can be used to remove stains from hot objects.

The sequence of actions is described above.