Do-it-yourself oven for working out: drawings, video and description of the manufacturing process

For heating technical rooms such as garages, workshops and utility blocks, a do-it-yourself stove can be made. Drawings, videos and additional information about the creation process will allow you to better understand the basic principles of building such a structure.

The content of the article

Positive and negative qualities

Before starting work, it is recommended that you familiarize yourself with the pros and cons of furnaces operating on the presented type of liquid fuel. Having evaluated the positive and negative points, you can decide whether it is worthwhile to engage in self-production of the heating structure.

List of main advantages

First of all, it is proposed to consider a list of the main advantages:

- acceptable fuel consumption;

- fast ignition;

- relatively simple device;

- the ability to create a water circuit;

- quite compact size,

- ease of use.

Helpful information! If necessary, a furnace operating on waste oil can be integrated into a hot water heating system by placing pipelines for the coolant in certain places.

Several minor flaws

Do not forget about the disadvantages that such ovens still have. The first is the rapid cooling of the structure. Normal heating is provided only during fuel combustion. However, for utility rooms, this disadvantage is not significant.

Another disadvantage is the need for frequent cleaning. chimney and the oil chamber itself. However, in fact, it all depends on the operating time of the structure.In garages and workshops, stoves are not constantly heated.

About the main types of structures

Not all types of ovens can be made at home by hand. Drawings, videos and technical data for certain types of structures will be a useless application due to their complex design. You can independently make only conventional pyrolysis burners, which are assembled on the basis of ready-made containers or using metal sheets.

As for models with a drip feed of liquid fuel, it is hardly worth trying to make them yourself. Such designs are economical in fuel consumption, but are difficult to manufacture. In addition, they are sensitive to the quality of the fuel used.

Do-it-yourself stove for working out: drawings, videos and other useful information

Although many specialty stores have a working oven, not all consumers are eager to buy it. Many of them are trying to find a more economical solution, which is to build the structure on their own. It is assembled from inexpensive items.

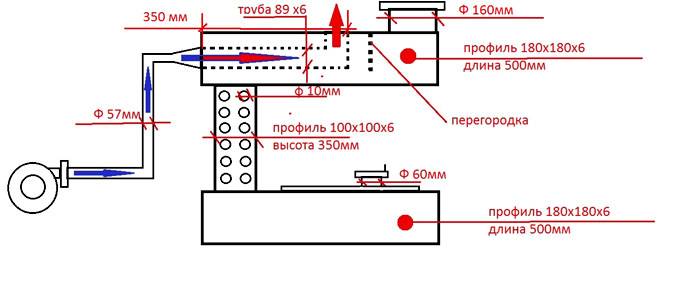

Making a waste oil furnace with your own hands: drawings of structures from a gas cylinder

An unnecessary gas cylinder can be taken as a basis for a future design. Its walls are quite thick, so they will burn out for a very long time. In addition, such a container has a suitable shape. Additional materials will require metal pipes, corners and sheets.

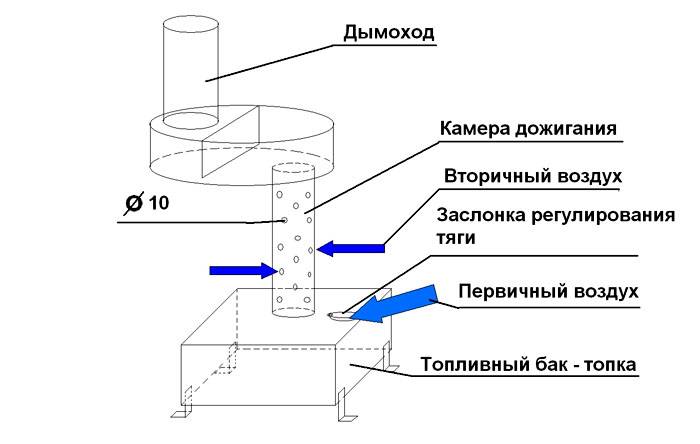

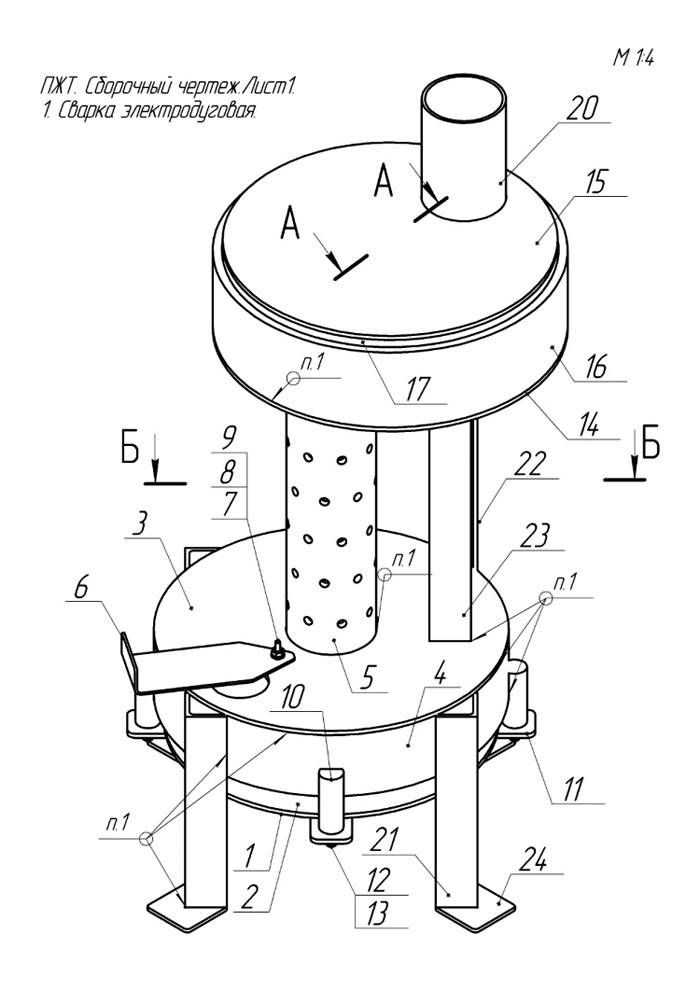

The interior must be divided into two combustion chambers. One will be at the bottom and the other at the top. On the lower side, legs from metal corners are attached by welding. A partition is attached to the cover of the upper chamber in the same way. It should be located closer to the chimney.

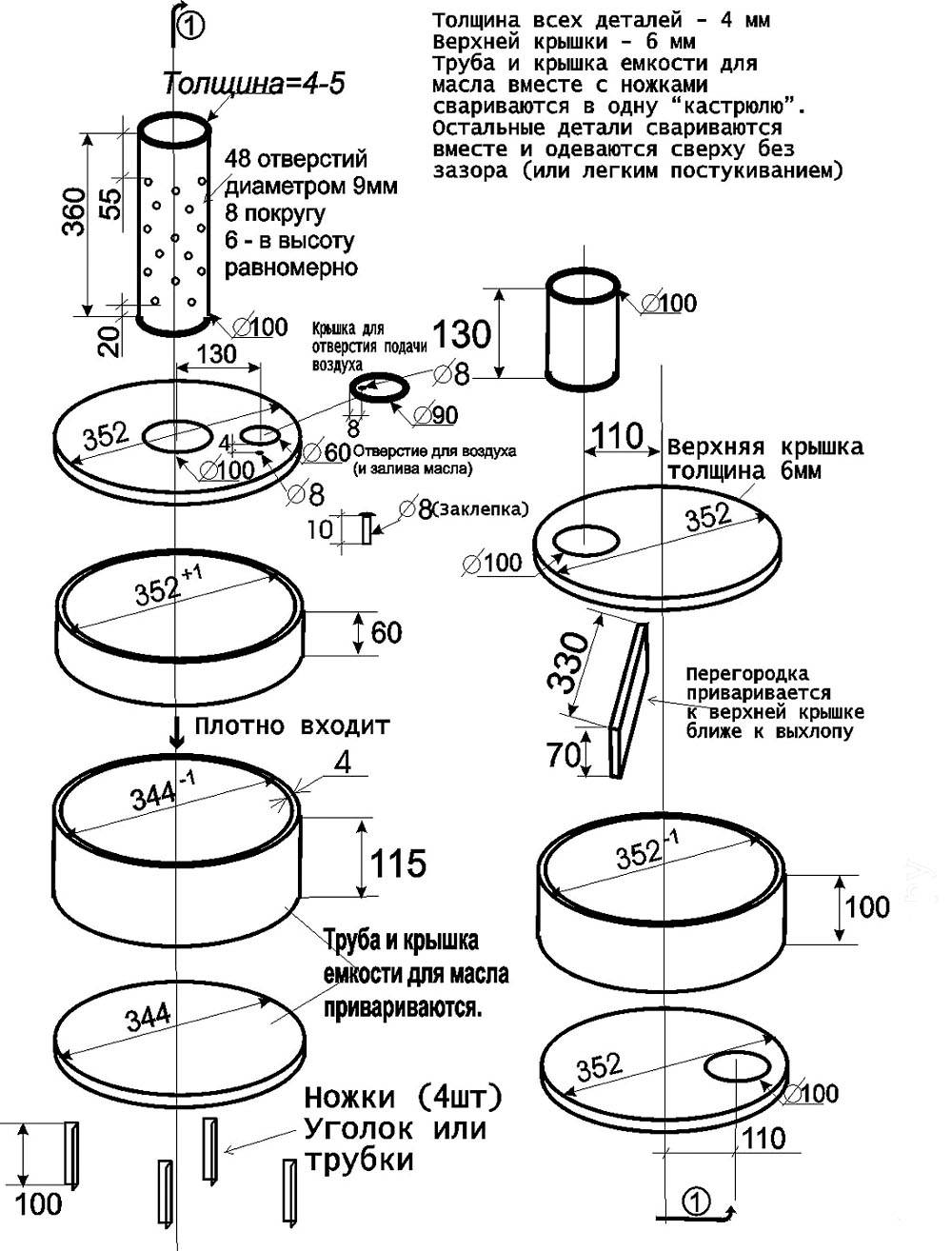

Two circles are cut from the steel sheet. The first one will act as a removable cover for the bottom camera. The second circle will create the bottom of the top compartment. In the blanks, holes are made in the center corresponding to the diameter of the chimney.

48 holes are drilled in the connecting pipe, eight of them are made in a circle, and six in height. Their diameter should be 9 mm. This is necessary for the afterburner, in which the burning vapors will be saturated with oxygen. At the final stage, a chimney is connected to the structure.

In the finished drawings of the waste oil stove, you can find the specific dimensions of certain parts. If they are not indicated, then you must make measurements yourself.

Creation of a waste oil furnace with a water circuit from metal sheets

Above, we talked about the construction of a finished container in the form of a gas cylinder. However, many want to know how to make a working furnace from ordinary metal sheets directly with a water circuit. The thickness of the steel should be 4 mm for the walls and 6 mm for the lids and bottom.

Blanks are cut out from individual sheets according to the drawings. They are cut out with a grinder, after which they are welded together around the perimeter. After manufacturing, seams are checked for tightness without fail. A 6x6 mm hole is made in the cover of the lower compartment for filling fuel.

Holes are drilled in the connecting pipe, as in the case of a gas cylinder structure. A chimney is attached to the top cover.

Basic rules of operation and maintenance

To protect yourself when using a homemade stove, as well as extend the life of the structure, you must adhere to some rules:

- it is prohibited to fill the lower compartment with liquid fuel by more than 66 percent;

- for ignition, you must first ignite the paper sheet, and then lower it into the lower tank;

- the required operating mode is set by adjusting a special damper;

- during operation, it is not allowed to use other types of liquid fuel, the design is intended exclusively for testing;

- you cannot leave the fired up stove unattended for a long period of time;

- fastening the structure to the walls of the building and using high stands should be avoided;

- it is forbidden to place the stove directly under shelves or other objects that may fall;

- flammable substances should not be kept in the immediate vicinity of the heating device;

- the room in which the stove will be used must have good ventilation;

- water should not get into the oil, otherwise it will foam and slowly spill out;

- the contacting surfaces of the room must be made of non-combustible materials;

- cleaning the internal parts of the structure is allowed in any convenient way;

- there is no need to add fuel after firing up, the filled portion of the mining should completely burn out.

Note! In the absence of extra money, a do-it-yourself stove is made for working off. Drawings, videos and other information are required to fully familiarize yourself with the construction process.

Summarizing

After studying the materials presented, you can see the process of making a homemade stove in the video. Testing for this design is the main and only type of liquid fuel. With proper assembly, heating structures can serve for a relatively long time. However, much depends on the quality of the materials used in each case.

Video: do-it-yourself oven for working off!