Wooden beams are the best solution for a home intended for permanent residence

Recently, they prefer to build residential buildings using natural materials. Wooden beams are the best solution for a home when it comes to environmental friendliness. In this regard, a large number of individual construction objects are constructed from it.

The content of the article

- 1 Positive and negative points

- 2 The main types of material

- 3 Some projects of houses from a bar: prices and photos

- 4 Additional thermal insulation of buildings

- 5 Basic methods of connecting elements

- 6 Summing up: timber is the best solution for the home

- 7 Video: vertical bar. New technology of wooden housing construction

Positive and negative points

Immediately before deciding on the choice of material for building a house, you should definitely familiarize yourself with its main advantages and disadvantages. After the ratio of positive and negative factors, certain conclusions can be drawn.

List of benefits

The list of positive qualities is quite extensive:

- low thermal conductivity level allows you to build warm structures with a relatively small wall thickness;

- due to the natural origin of the material, a pleasant microclimate is formed inside the finished buildings during operation;

- the elements are easy to process, so there are no additional difficulties during construction;

- the technology of laying the timber itself is quite simple, thanks to which developers can carry out work on their own.

Some cons

Although timber is the best solution for a home, it also has disadvantages. The main one is the shrinkage of the building. Because of it, the final finishing is allowed only some time after construction. Usually the waiting period is at least 6 months.

Wood is a combustible and biologically sensitive material and therefore requires additional processing.Coating with protective compounds increases the life of the building.

The main types of material

The most affordable option is considered to be a conventional edged beam, which has even identical edges on four sides. Its surface, as a rule, is not sanded, therefore, after work, additional finishing of buildings is required. However, it is recommended to lay a layer of thermal insulation under the facade cladding.

A completely acceptable option from the point of view of economy is a profiled beam, which is a product with precise geometry and special locks in the form of grooves and ridges. Since its sides are completely sanded, there is no need to spend money on facade decoration.

Prices for the purchase of profiled timber:

| Section size, cm | Overall dimensions of the workpiece, cm | The volume of raw materials in one workpiece, m³ | Number of blanks, pcs / m³ | Cost, rub / m³ |

|---|---|---|---|---|

| 10x15 | 9.2x14.2 | 0,09 | 11,1 | 7300 |

| 15x15 | 14.2x14.2 | 0,135 | 7,4 | 7300 |

| 15x20 | 14.2x19.2 | 0,18 | 5,5 | 7300 |

| 10x20 | 9.2x19.2 | 0,12 | 8,4 | 7300 |

| 20x20 | 19.2x19.2 | 0,24 | 4,16 | 7300 |

| Cutting bowls on material | ||||

| 10x15 | 9.2x14.2 | 0,09 | 11,1 | 9300 |

| 15x15 | 14.2x14.2 | 0,135 | 7,4 | 9300 |

| 15x20 | 14.2x19.2 | 0,18 | 5,5 | 9300 |

| 10x20 | 9.2x19.2 | 0,12 | 8,4 | 9300 |

| 20x20 | 19.2x19.2 | 0,24 | 4,16 | 9300 |

A more technologically advanced material can be called glued laminated timber, because it implies longitudinal gluing of individual pieces of wood (lamellas) using automatic machines. After the applied composition has hardened, the workpiece is profiled and planed. This production technology reduces shrinkage to a minimum.

Useful advice! People who value the ecological purity and aesthetic appeal of wood are advised to purchase profiled products for construction, since they do not contain additional substances and do not require finishing.

| Dimensional parameters of the workpiece, cm | The volume of raw materials in one piece, m³ | Number of blanks, pcs / m³ | Cost, rub / m³ |

|---|---|---|---|

| 10x10 | 0,06 | 16,6 | 6000 |

| 10x15 | 0,09 | 11,1 | 6000 |

| 10x20 | 0,12 | 8,5 | 6000 |

| 15x15 | 0,135 | 7,4 | 6100 |

| 15x20 | 0,18 | 5,5 | 6100 |

| 20x20 | 0,24 | 4,16 | 6100 |

Some projects of houses from a bar: prices and photos

Further, it is proposed to consider some data from the standard design documentation for buildings of the most popular sizes. Basically, using this material, medium-sized objects are being erected. It is recommended to build large structures of bricks.

Related article:

Projects of houses from a bar for permanent residence. Interesting layouts and advantages of glued and profiled timber in a separate publication of our portal.

Interesting projects of one-story houses from a bar with prices

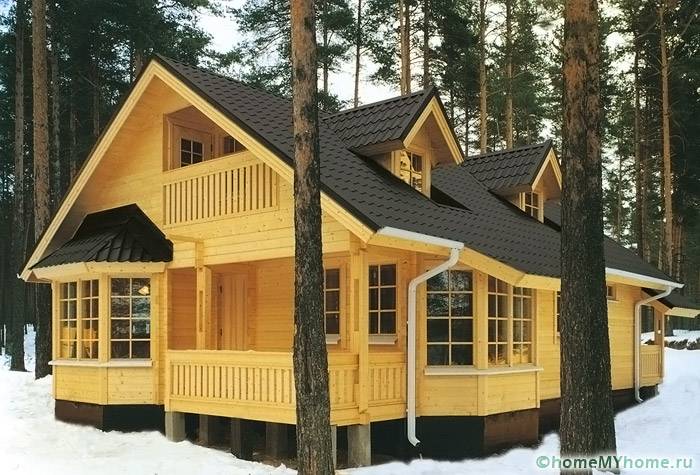

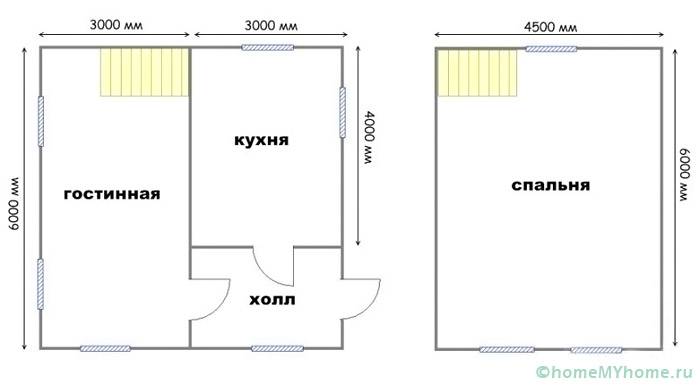

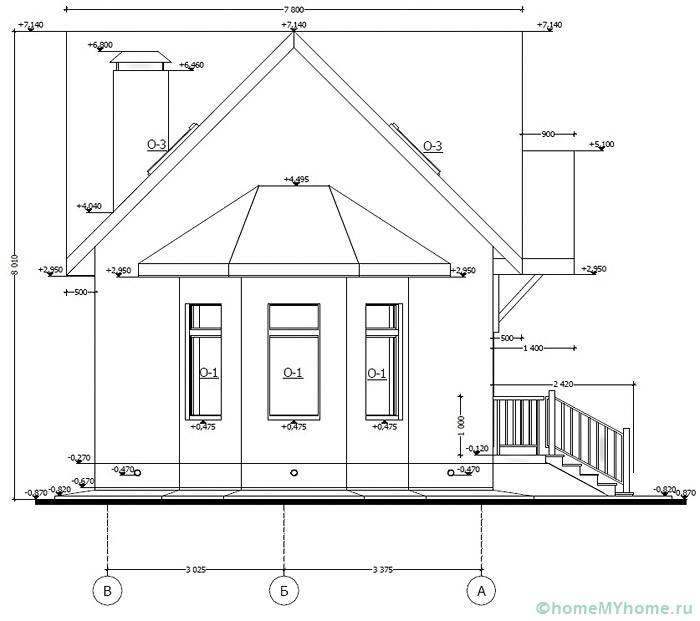

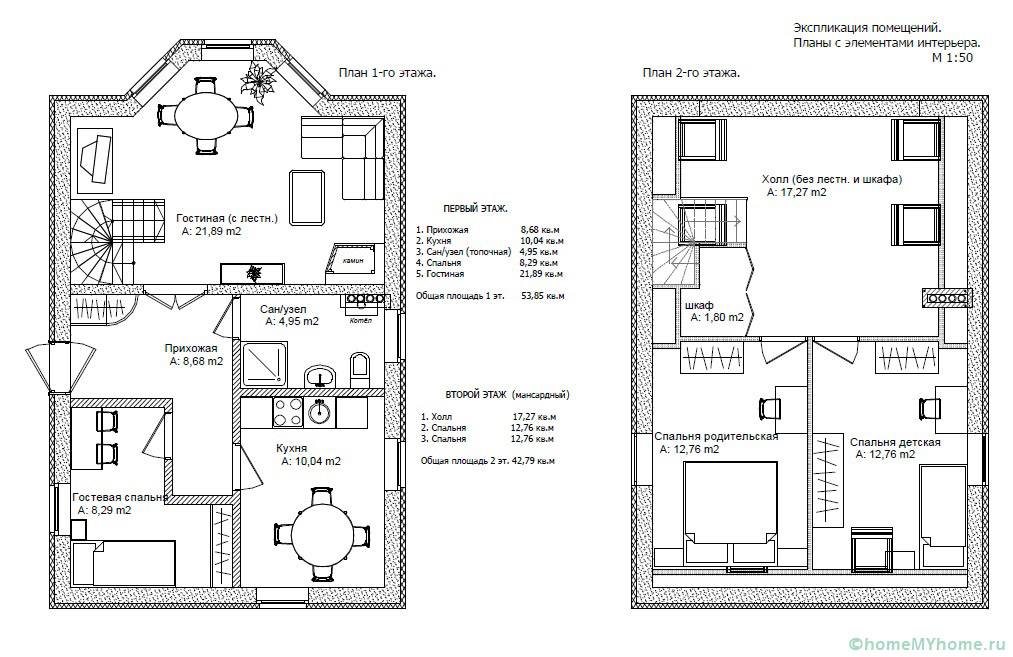

One of the most common options is considered to be a 6x8 m residential building.With such dimensions, all the main premises can be quite successfully located. Attic device upstairs allows you to significantly expand the living space. For permanent residence, the dimensions are quite suitable.

The most promising in this case are houses made of laminated veneer lumber. Projects and their prices are very diverse. If you wish, you can choose a building not with a gable, but with mansard roofto expand the space upstairs. However, the cost of an object increases with the complexity of the roof structure.

The second most popular option is a 6x6 m house. When erecting it, it is possible to save on materials, but there is still enough space for a comfortable stay. These can be houses made of profiled timber. Their prices and designs can also vary significantly.

With such dimensions, it is unlikely that it will be possible to experiment with the layout. There are not so many options left as in the case of large structures. However, it is still possible to achieve a convenient location of the premises.

Examples of layouts of log houses

Approximate prices for finished buildings from profiled timber are presented in the table:

| Dimensions in meters | Living area in square meters | Average cost in rubles |

|---|---|---|

| 6x6 | 50,4 | 500-550 thousand |

| 7x7 | 68,6 | 750-800 thous. |

| 6x9 | 75,6 | 800-850 thous. |

| 7x9 | 88,2 | 850-900 thous. |

| 9x8 | 100,4 | 950-1000 thous. |

We propose to consider the prices for turnkey houses made of glued laminated timber, the cost of which is slightly higher than in the case of profiled counterparts.

| Name | Operating temperature range | Tank weight, kg | Average cost, rub |

|---|---|---|---|

| TechnoNICOL No. 24 | -5 ° С ... + 80 ° С | 20 | 1240 |

| TechnoNICOL No. 27 | -5 ° С ... + 80 ° С | 22 | 1300 |

| TechnoNICOL No. 21 | -35 ° С ... + 110 ° С | 20 | 1950 |

| MGH-G Grid | -40 ° С ... + 100 ° С | 18 | 960 |

| MGH-G Grid | -40 ° С ... + 100 ° С | 45 | 2500 |

| AquaMast | -10 ° С ... + 40 ° С | 18 | 1160 |

| AquaMast | -10 ° С ... + 40 ° С | 10 | 830 |

| AquaMast | -10 ° С ... + 40 ° С | 3 | 230 |

Various photos and free drawings of the project of a house from a bar with a bay window

With the use of timber, it became possible to erect objects with a complex configuration and impressive dimensions. Seeing photos and free house project drawings from a bar with a bay window, many developers have a desire to reproduce them directly on their site.

Such structures look very solid on the site. In addition, several square meters of usable space appears inside. When decorating the interior space, excellent prospects open up.

Additional thermal insulation of buildings

In case of incorrect calculations of the wall thickness, the timber structures should be insulated from the outside by placing a suitable type of thermal insulation under the facing coating. When carrying out work, the following types of materials are used:

- mineral wool (basalt or fiberglass based);

- extruded polystyrene foam;

- polyester insulation;

- ecowool;

- foamed polyethylene (perforated).

Important! Despite the abundance of thermal insulation materials on the modern market, experts recommend choosing those products that are vapor permeable. These include, for example, mineral wool.

Basic methods of connecting elements

The joining of the timber is carried out with or without the remainder. In the first case, a certain part of the element protrudes beyond the wall, while in the second it does not. In recent years, the second option has become more popular.

Methods for combining components with the remainder:

- a one-sided lock involves the creation of a perpendicular groove on the upper side;

- a double-sided lock implies the formation of cuts immediately from the bottom and from the top;

- a four-sided lock is more complicated to manufacture, since the grooves are arranged directly from all sides.

Options for joining a bar without a remainder:

- end-to-end with bandaging;

- on root spines;

- with a dovetail lock;

- into the floor of a tree;

- on dowels.

Summing up: timber is the best solution for the home

The study of the information presented makes it clear that it is difficult to imagine individual construction without a wooden beam - the best solution for houses intended for permanent residence. Other materials cannot match wood in terms of thermal insulation qualities and cost.

Video: vertical bar. New technology of wooden housing construction