How to create high-quality concrete mixtures: a table of the proportion of concrete per 1m3

Concrete is used in any construction of industrial and individual importance. The quality characteristics of the material depend on the correct use of the components and their correct mixing. The presented table of the proportion of concrete per 1m3 will help to select the ratio of all components of the mixture for certain structures.

The content of the article

- 1 Specifications and properties of concrete

- 1.1 Concrete grades and areas of their application

- 1.2 The main components of the concrete solution

- 1.3 Material consumption: table of the proportion of concrete per 1 m3

- 1.4 Video: the ratio of the components of concrete M300

- 1.5 Features of the preparation of a solution for the foundation

- 1.6 Calculators for calculating the weight and volume of concrete ingredients for pouring the foundation

- 2 M200 concrete (strength class B15)

- 3 M300 concrete (strength class B22.5)

- 4 Solution preparation steps

- 5 Helpful hints

- 6 Video: making concrete mix

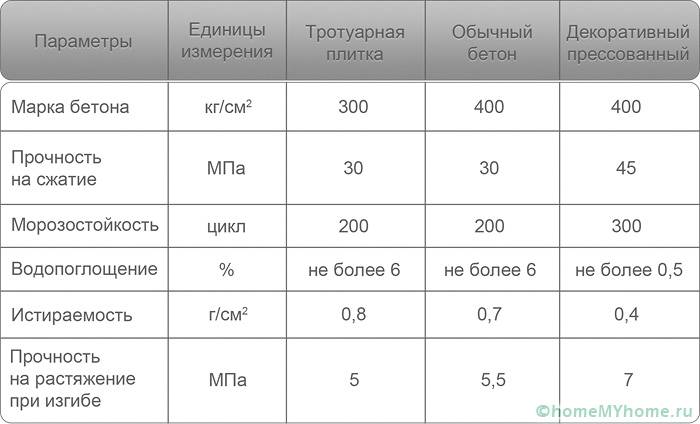

Specifications and properties of concrete

Concrete is formed by mixing two components: water and cement. This produces a hard cement stone.

For a stronger composition, the addition of special fillers is required. Gravel, sand and crushed stone allows you to create a material, as it were, reinforced with reinforcement. This affects the improvement in strength. At the same time, the property of deformation weakens. Without additional components, microcracks are formed in the cement composition.

Depending on the strength of concrete, it is divided into certain classes. The numerical value of the brand and the variety by class determines for which type of construction this material is suitable.

The concrete grade is determined at the stage of project preparation.

Concrete grades and areas of their application

Different brands of mixtures are used for certain types of buildings. Concrete consumption per 1 m3 of concrete depends on various factors. When choosing sand, it is necessary to take into account the composition of its impurities and particle size. For crushed stone, the density indicator and the content of foreign inclusions are important.

The concrete grade is important for the type of work for which the mortar will be prepared. Various types are used for pouring foundations, erecting walls and for concrete screed.

For high-quality hardening, installation work must be carried out at positive temperatures. The solution hardens within 12 hours after pouring. After two weeks, the material gains most of its strength, and after a month the structure is completely ready for use.

Helpful information! Work is not performed at negative temperatures, since the water in the mixture will freeze and the strength of the material will be lost.

The main components of the concrete solution

Using the table of the proportion of concrete per 1m3, it is necessary to pay attention to the compound components of the solution. Their quality characteristics matter:

- Cement should not have a long shelf life. The optimal rate is less than four months. Raw material bags must be free from hardened elements.

- Water should only be used fresh.

- There should be no clay impurities in the sand. This mixture will have a yellowish color. It is better to use gray or white sand for the solution.

Related article:

How much does a cube of sand weigh? What types are there? How much does one cube weigh? How much does a KAMAZ body fit? Read more in a separate publication on our portal.

- Crushed stone should not contain additional inclusions. The best option is the use of crushed stone with a granite content.

For concrete mortar, limestone or gravel can be used. Granite is characterized by low water absorption and frost resistance. To improve some of the characteristics of concrete, special additives are added to the mixture:

- Plasticizers increase the plasticity of the material. Hydraulic seals protect the structure from excess moisture.

- Dusting agents increase the strength of raw materials and reduce the risk of abrasion.

- Antifreeze additives allow the mixture to be used at low temperatures.

- Set retarders help control the set time of the formulation.

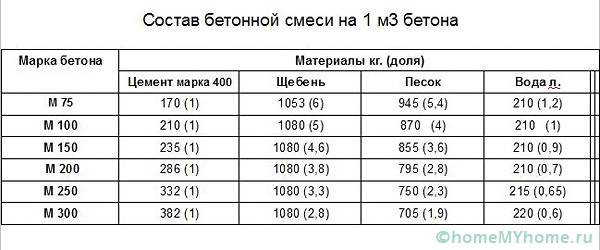

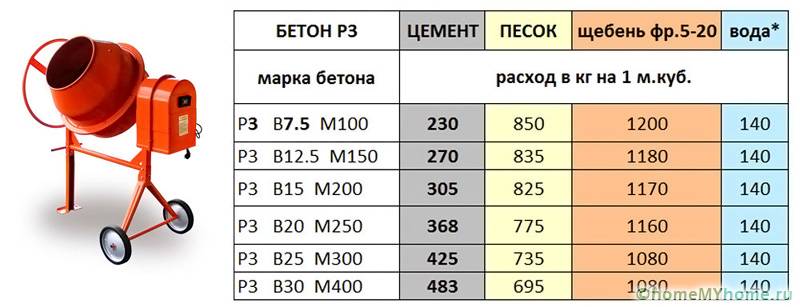

Material consumption: table of the proportion of concrete per 1 m3

The quality of the concrete used is influenced by the brand of cement and the purpose of the structure. The table of the proportion of concrete per 1m3 allows you to determine the required material consumption.

For the production of concrete of different grades, a different number of constituent components will be required. For example, you can calculate the composition of concrete m200 per 1 m3. For 10 buckets of cement, 35 buckets of sand will be needed, and 26 buckets of crushed stone. You will need 5 buckets of water. Knowing the density of each substance, you can calculate its weight in a bucket.

Video: the ratio of the components of concrete M300

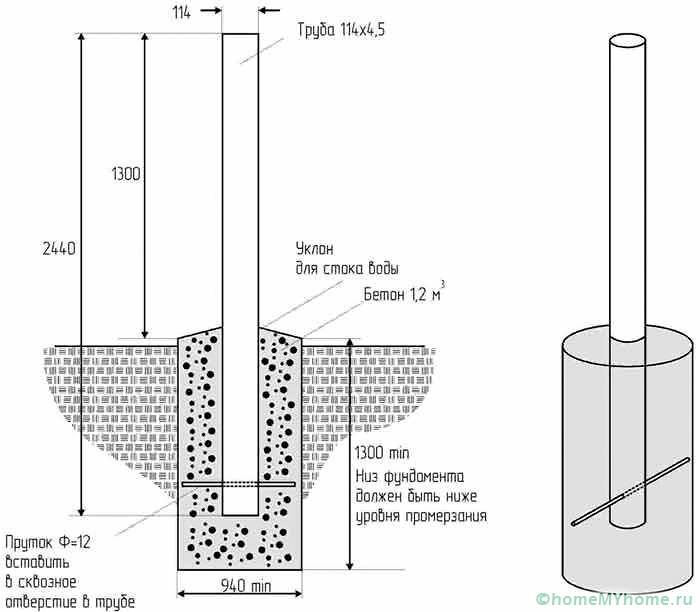

Features of the preparation of a solution for the foundation

When building small objects, it is worth counting the material in buckets. A similar method is useful if the solution is used in small portions.

When determining the composition of concrete for a foundation, the proportions can be taken from the table below. In this case, the concrete is selected for the foundation in buckets. The figures will differ depending on the brands used.

Important! The main strength of the foundation is given by filling in the form of crushed stone or gravel. You cannot use various types of river or sea pebbles, as they have a polished surface, which makes it difficult to adhere well to the solution.

Calculators for calculating the weight and volume of concrete ingredients for pouring the foundation

M200 concrete (strength class B15)

M300 concrete (strength class B22.5)

Solution preparation steps

After the consumption of materials for 1 m3 of concrete has been determined, you can start the main work. In individual construction, the concrete mix is produced from components that are measured in buckets.

When measuring the right amount, it is worth taking care of the dryness of the shovel and the bucket for the dry mixture. To get more accurate proportions, sand or rubble in the bucket needs to be pressed down a little and made denser around the edge of the container. It is recommended to mix the measured components in a bulk container. At the same time, small depressions are made in the mixture, where the measured cement is also poured. It will help to determine the amount of all components, as well as the weight of concrete in 1m3 - a table. All components are thoroughly mixed until a homogeneous mass is obtained. Then, in the resulting mixture, it is necessary to make a hole in the form of a cone and pour water there. The mixture is poured from the edges to the middle. In this case, the water is gradually absorbed. After dissolving the first portion of the liquid, additional water is poured in. This is done until the solution becomes the required consistency.

Mixing the solution in a concrete mixer consists of the following stages:

- The calculated amount of water is poured. About 10% is left to add later.

- Cement is added.

- Sand is falling. Kneading is carried out for several minutes.

- Additives are added: reinforcing mixtures or plasticizers.

- A filler from crushed stone or gravel is filled in.

If it is necessary to add water, a small amount of cement and water are mixed separately, and then added to the main mixture. Mixing in a concrete mixer lasts no longer than 20 minutes so that the mixture does not set inside the equipment.

Helpful information! Experts do not recommend making a too liquid solution. In this case, voids can form in the material, which will greatly affect the strength indicator.

Helpful hints

Some advice from experts will improve the efficiency of working with the material:

- In case of poor-quality filling, voids will appear inside the composition, which only special equipment will help to remove.

- For small structures, brand 100 products are suitable.

- While creating strip foundation it is recommended to use the composition of the brand 200.

- It is impossible to erect a tape base during periods of cold weather. If the liquid freezes inside the concrete, the volume will increase and the structure will collapse.

- When pouring the foundation in summer, it should be sprayed with water for several days after installation. As a result, the structure will not crack and will adhere evenly over the entire surface.

For uniform drying of the concrete structure, it should be covered with foil. This will prevent the outer layer from drying out quickly and the compound will harden more evenly. Drying time depends on the thickness of the concrete layer.

Using the table of proportions of concrete application, you can create a high-quality and homogeneous mortar. This will guarantee the durability and strength of concrete structures. Compliance with technical standards in the manufacture of a building mixture is important.

Video: making concrete mix