Soffits for roofing: installation technology

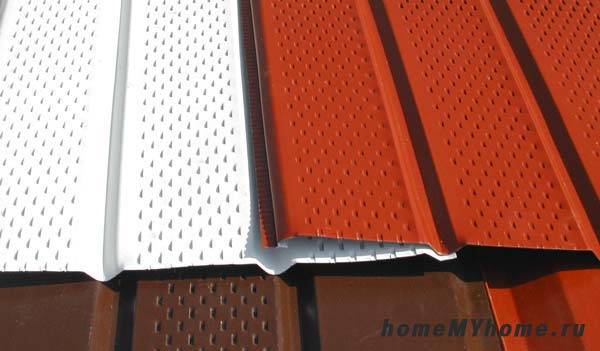

ABOUTThe lining of the cornices completes the roofing work - the most expensive work in the entire technological process. Sheathing serves as an obstacle for birds and small rodents, protects cavities from snow and water ingress, and provides the necessary ventilation of the roof structure. Soffits for roofing are architectural elements, which are horizontal panels that are just attached to the lower part of the roof overhang and cover the "insides" of the cornice.

The content of the article

Materials for filing overhangs

Soffits perform two main functions - protective and ventilation, so the materials for their manufacture must be moisture resistant and durable. In order to ensure sufficient ventilation, soffits are supplied with special holes, which are manufactured in the factory. It is not forbidden to use as a filing and materials that were not originally intended for these purposes - boards, plywood, galvanized sheet. In this case, the labor intensity of the process will increase significantly, and the appearance will suffer, therefore, industrial soffits are preferable.

By the type of materials, spotlights are as follows:

- vinyl - special panels made of frost-resistant polymer, which have perforations over the entire area or in the center, painted in various colors, do not fade in the sun;

- metal soffits for filing roofs with PVC coating - structurally very similar to vinyl soffits, have high strength, are safe from the point of view of firefighters, but they can fade in the sun;

- galvanized sheet is a cheap and durable material, but it does not have perforations and special structures for fastening;

- wooden lining is an expensive material that is exposed to moisture, it requires careful pre-painting, and installation must be carried out while maintaining ventilation gaps.

Factory made soffits are equipped with special fasteners.During installation, they are connected "in a lock", and to attach them to the guides, 4 - 6 self-tapping screws are required per piece. Materials such as sheet metal or lining are attached using ordinary roofing screws, so the filing does not look very neat.

Video review of Vox roof spotlights

Soffit installation technology

After completing all the roofing work and installing drainage systems, the soffits for filing are installed roofs... Depending on the configuration of the overhang, only the bottom edge or the bottom and side ends are sewn. If spotlights are installed in the spotlights, then the wiring is also carried out at this stage. Binding can be done both horizontally and at an angle. In the first case, ventilation will be more efficient.

When hemming the side overhangs, leave ventilation holes or use perforated material. When processing overhangs from the side of the pediment, you can use solid soffits without holes and attach them directly to the protruding beams of the sheathing, without carrying out any preparatory work.

Preparatory work

The mounting technology depends on the material used. For all types of spotlights, it is necessary to pre-assemble the fixing guide rails. They come in the form of a wooden bar or in the form aluminum profiles... Metal soffit less than 60 cm wide can be fixed in just two points. Soffits made of all types of plastic, wood or sheet metal must have additional fastening in the middle. Wooden guides must be pre-treated with special compounds that protect against fungus and prevent combustion. The aluminum profile does not need preliminary preparation, however, you should pay attention to its thickness, it should be at least 0.6 mm.

Fastening elements

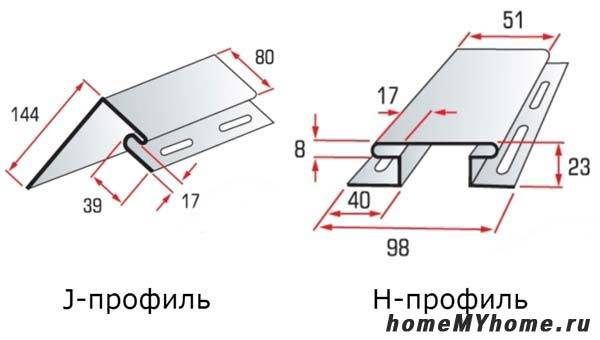

Factory made soffits are equipped with special profiles that greatly facilitate the installation process. The profile can perform the function of anchoring (J-profile) or connecting and hiding seams (H-profile). The latter is used to deduce angles. The fastening profile is hung on the guide rails using self-tapping screws, and the soffit is inserted into it like a rail. If its length is less than 60 cm, such an attachment will be sufficient. In order to close corners and gaps and give the overhang an attractive appearance, it is necessary to close the corners and cuts with a decorative corner.

General installation guidelines

The filing of the eaves of the roof with soffits is carried out after the completion of the roofing work. Roofing cake is technologically the most complex element of a building, it consists of many layers. From above and below it is protected from water ingress and mechanical damage, and remains open around the perimeter. The overhang has the following functions:

- drainage of sediments and protection of the upper supporting structures from water;

- base for the installation of drainage systems;

- ventilation of the roof structure and attic space;

- the overhang can be used as a base for installing street lighting, therefore it must have an aesthetic appearance.

In an open, unprotected overhang, rafters are exposed to weathering, which suffer from moisture, rot and deform when dry. When wet, the insulation loses its properties, and the thermal insulation of the ceiling deteriorates significantly.

There are two opinions on how the overhang should be - ventilated or not. The technology requires that the roofing cake and attic have natural ventilation ducts. As such, special air vents can act, which are operated in different modes, depending on the season, atmospheric precipitation.The ventilated overhang is protected from moisture penetration, therefore it can be operated all year round.

Which spotlights to choose?

All soffits perform the same function, therefore the choice of material is influenced only by the simplicity and ease of installation, as well as the configuration of the overhang. The amount of materials used is not large, so the type of spotlights does not greatly affect the cost of work.