What is the best floor screed?

PWhen carrying out repairs and construction, one of the important activities is the manufacture of a screed on the floor. But it is not easy to immediately decide which floor screed is better. The quality of its manufacture directly affects the ease of laying decorative flooring, its reliability and service life. A high-quality screed provides the floor with a flat and smooth surface, resistance to mechanical stress, thermal, sound and waterproofingand also performs many other functions. In this regard, the issue of its manufacture must be taken with full responsibility.

The content of the article

Varieties of floor screeds

Using modern materials and technologies, you can mount the following types of floor screeds:

- Concrete;

- Cement-sand;

- Semi-dry;

- Dry;

- Wet;

- Plaster.

For the installation of concrete coverings, mixtures of various brands with various components in the form of crushed stone, sand, gravel, water, etc. are used. The color of the resulting screed is the same as that of the cement screed - gray. To prevent shrinkage of the floor covering, it is additionally provided for the production of expansion joints. The final processing of the resulting surface is carried out using diamond wheels. The advantage of this floor is the possibility of forming a mosaic pattern on it.

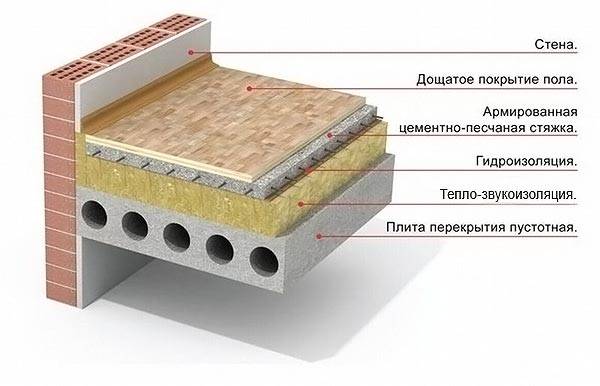

Cement-sand constriction layers are also common. The main materials for its formation are cement, gravel, sand and water. The strength of the resulting coating depends on the quality of the latter. This type can be used as both a rough and a finishing layer.

Progressive is the technology by which semi-dry tightening layers are mounted, which have high strength, quality and durability. They are distinguished by uniform shrinkage, absence of voids and cracks, clean installation, low cost due to ease of production and transportation.

Dry floors include floors that are formed without the use of concrete or cement mixtures. They are characterized by high laying speed and low weight. At the same time, during the work, the room is dusty with dry mortar particles.

Wet screeds are manufactured in the form of liquid mixtures intended for pouring floors. Using such a solution, you can get a smooth and even tightening layer due to its easy spreading over the surface. After the end of the pouring of the mixture, additional processing and leveling of the surface is required using special tools.

Gypsum screed is in demand due to its high environmental friendliness. Gypsum is used as a material for its manufacture. The advantage of this type of coating is the effective provision of optimal humidity and temperature in the room. But the gypsum constricting layer should be exploited taking into account the physicochemical properties of gypsum.

Types of screeds by functional purpose

Also, mixtures are leveling and leveling-thermal insulation. The first ones are made exclusively to give the base the required parameters in terms of height, surface evenness and, if necessary, in terms of slope. The second, in addition to the above functions, also provide thermal insulation of the room.

For residential and public premises, coatings with a low density and an average level of strength (self-leveling floors, dry, gypsum mixtures and the like) can be used. For the installation of floors intended for operation in conditions of high mechanical loads (sales areas, industrial buildings), it is necessary to use coatings of high density and strength (concrete compositions, mixtures with a high content of polymer binders).

Materials and tools for work

For high-quality and quick installation of the screed, a certain set of materials and tools will be required. In addition to the components that make up the tightening layer, you will need to use:

- Roulette;

- Level - rulers;

- Reiki - rules;

- Knife;

- Hydro level;

- Spatula and trowel;

- Roller;

- A construction mixer and a sufficient capacity.

What is the best floor screed in a new building?

When deciding which is the best rough floor screed in new buildings, you need to take into account the opinion of experts that in this case it is preferable to mount the floors using a cement-sand mixture to which expanded clay is added. The cost of all components of the coating is relatively low, therefore it is affordable. If you independently carry out the entire complex of work, the cost of the received coverage will be minimal, which is very important for new settlers. The manufacturing technique of this type of tightening layer is simple and has been used for a long time, therefore it does not cause any problems. During the installation process, it must be borne in mind that the drying of the layer occurs gradually, therefore it is important that the surface does not dry out very quickly. The longer the coating loses moisture, the stronger it will be.

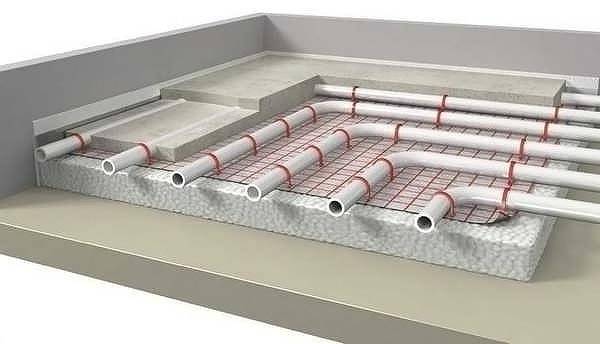

Which screed is better for a warm floor

Underfloor heating device usually involves the formation of a protective concrete layer made of a cement-sand composition. Also for these purposes, dry specialized mixtures (semi-dry screed) are intended. The latter option is more profitable, since less water is required to prepare the composition, and its drying time is shorter and the strength of the resulting layer is higher. To effectively perform its function with warm floors, the screed must be properly mixed and laid in accordance with the characteristics of the heating system.

Thus, it is impossible to say unequivocally which screed is better for a particular floor.Each type of backing layer is intended for floors with specific requirements. Therefore, in the process of selecting a suitable option, one should take into account the type of future floor covering, the level of mechanical stress, humidity and temperature, maintainability and environmental friendliness.

DIY video tutorial on screed construction