Laying laminate on a concrete floor with a backing

PThe ol should be warm, because when our feet freeze, the whole body cannot get warm. If you are the proud owner of a concrete floor, and in the role flooring chosen laminatethen the following material is for you. Laying the laminate on a concrete floor with a substrate must be carried out in accordance with all the rules. And there are quite a few of them. Otherwise, you will not get a beautiful floor, but something hunchback-unimaginable that will have to be changed in the near future. And it will not be cheap.

The content of the article

Calculations

Before laying a laminate on a concrete floor, you need to decide on its amount, choose a substrate and buy the tools necessary for the job. This step is very important as the right tools and backing can extend the life of the coating by helping to get the installation done right.

In order to calculate the amount, you need to follow these steps:

- Calculation of the floor area of the room. This is done by simple mathematical calculations: the width is multiplied by the length.

- To the resulting figure, you need to add 7% if you will lay the covering perpendicular to the windows, and 15% if diagonally.

- The resulting figure is divided into square meters, which are indicated on the packaging of the laminate: the result obtained is the number of packaging packages that need to be purchased.

Calculator for calculating the amount of laminate

As for the substrate, then everything is not as obvious as it seems, because many operational characteristics of the future floor will depend on its quality (thickness). Correct substrate:

- has a thickness of 3 to 5 mm;

- made of polyethylene or cork;

- has antibacterial impregnation;

- should not allow moisture to pass through.

Tools that you need in the work:

- pencil;

- ruler or corner;

- roulette;

- mallet, rubber hammer;

- sealant;

- jigsaw;

- wooden blades;

- steel bracket.

Surface preparation

We check the quality of the base, that is, the concrete floor. It should not have horizontal drops, bumps and other defects. Even if you remove the old coating and it is intact, this does not guarantee the ideality of the concrete base.

The presence of pits and bumps will lead to the formation of cavities under the laminate, and this will reduce its life. Weak areas like these will lead to unpleasant noises when moving across the floor. A difference of 2 mm for every 2 m of floor length is considered normal.

The already mentioned cavities under the laminate are sure to bring troubles, such as:

- The appearance of squeaks.

- Failure of locks.

- They can cause unwanted occupants, such as insects, to colonize the area under the laminate.

When preparing a concrete base, it is necessary to achieve its smoothness, as it will ensure a tight fit of the coating, solidity and a flat surface horizontallyand.

Related article:

Can laminate flooring be laid on top of laminate flooring? How to properly install on an old floor, wood floor or linoleum? Read more in a dedicated publication.

Surface preparation methods

Before carrying out laying laminate on a concrete floor with a backing, level it. If the concrete area has a monolithic structure, and there are no significant defects, then local repair work will be sufficient. Cracks are cleaned to a monolithic layer, and this must be done along the entire length. Those pits that appear must be carefully primed with a special compound. Then it is poured with a cement compound until it reaches a level with a common layer. For this, dry repair mixes are perfect, in which you only need to add water.

If there are large differences or defects, then a new screed will have to be poured. We will not describe this process in detail, as it will take too long. It is worth noting: such a fill can select useful space in height, so when carrying out this operation, take into account laminate thickness and substrate.

If the differences are not very large, then the best option would be to use self-leveling mixtures. They quickly freeze, and all you need to do is dissolve them in the required amount of water and pour them onto the floor, then walk with a special needle roller to remove air bubbles.

Another preparation option is laying on a concrete floor. OSB sheets moisture resistant or Fiberboard... Yes, this is an excellent option for laminate flooring, but it takes up a lot of height - about 15-20 cm. By the way, the sheets also need to be mounted on a flat floor. We remember what the cavities under the coating will lead to.

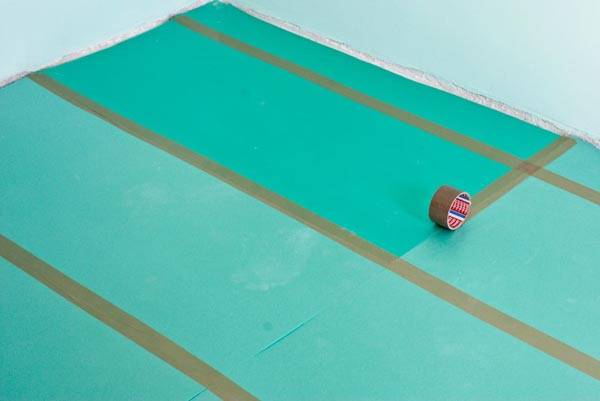

Laying the substrate

There should be two substrates on the concrete floor when laying the laminate, each with its own functional purpose.

# 1. The vapor barrier can be a simple plastic wrap. It must be laid so that there are no gaps for moisture penetration. To do this, firstly, it is necessary to overlap, and secondly, to glue the joints with special tape. You should not save on thickness; for high-quality vapor barrier, it should be at least 200 microns.

# 2. Soundproof and softening backing. This is one multifunctional material. It must be laid on top of the film. The main tasks of the substrate:

- Cushioning impacts on concrete floor when walking on the floor.

- Soundproofing.

You only need to lay it end-to-end, fasten the honey strips with the same tape.

As for the choice of the substrate itself, there are two options on the market - natural cork and polymer. Both the one and the second perfectly copes with the tasks.But cork is a natural material and a polymer is chemical.

Installation of laminate

Having chosen the styling method, you can start it. Regardless of the option chosen, this should be done from the corner of the room. The laminate has two connection options:

- Lock - this means that the panels are inserted into each other in a horizontal plane. Panels from the second row are inserted into the panel of the second row, after which they are knocked out with a mallet or rubber hammer in order to minimize the gaps between them.

- Click is a lock connection. One panel is inserted into another at a 45-degree angle and lowered to the floor until you hear a characteristic click. When you reach such connections to the wall, and there it is impossible to crank something like that, a bracket comes to the rescue: we fix one side in the expansion joint. Tap the other end to reduce the seam.

conclusions

Laying laminate flooring on a backed concrete floor is convenient and practical. The underlay will extend the life of the coating and guarantee its cushioning, as well as the absence of sound. It is important to carry out all the laying operations correctly, which will provide only pleasant impressions both from work and from using the coating.

Video: Laying laminate on a concrete floor with a backing