Warm floor under linoleum on a wooden floor - installation secrets

Ba budget option for repairing or facing floors with a minimum rise of the lower level is warm floor under linoleum on a wooden floor of water or electric type. This design provides additional heating, minimizes load on supporting structures, saves working space in interiors, and can be easily manufactured by yourself.

The content of the article

Video: installation of a warm floor under linoleum and laminate

Brief information about the types of underfloor heating

Electric and water heating systems for floor coverings have been created for various operating conditions. However, using a limited number of technologies to make a warm floor for linoleum on a wooden floor. For this you can apply:

- water floor - only floor systems in which pipes laid in the cavities of extruded polystyrene foam;

- electrical circuit - amorphous metallized tapes, bimetallic or carbon films.

All other additional heating systems cannot be laid on a wooden floor or revetted with linoleum. This requires screeds that seriously load the ceiling, raising the level of the cladding by 5 - 7 cm. This is unacceptable in operated interiors, since it will require dismantling the door leaves, which will stop closing. The steps formed between the rooms reduce the quality of living.

The nuances of a wooden base

It is much more difficult to lay a warm floor under linoleum on a wooden floor than in floor joists along beams, inside floor screeds on the ground or monolithic floors. The features of the linoleum / warm floor / floorboard system are:

- it is impossible to make a screed on a wooden floor, the material does not have sufficient strength, dry mixes, concrete cracks;

- by underfloor heating pipes you cannot walk, they must be sunk into the base;

- linoleum does not have structural rigidity, unlike laminate, floorboards, parquet, tiles, so the contours of the underfloor heating must be embedded / recessed in the base with a perfectly flat surface.

Therefore, only the three above-mentioned underfloor heating systems are suitable for these particular operating conditions. Even minor irregularities are emphasized by thin-walled roll material; above the pits, the linoleum is guaranteed to break from stress.

Preparation

All of these systems of underfloor heating (TP) refer to modular, film, roll modifications. Therefore, it is impossible to align the base with them. In addition, they do not have rigidity, they are mounted on pre-leveled surfaces. Therefore, preparation consists of operations:

- revision - the areas on which the boards sag, have flatness defects are marked;

- replacement of lags - in individual areas or entirely along the entire length after complete opening of the floor;

- processing - all available wooden elements of the exploited floor are covered with Fire-Bioprotection or an antiseptic + fire retardant, since linoleum has a higher resource in comparison with sawn timber;

- production of ventilation ducts - cuts in logs, gratings on the floor surface with a total size of 1/400 of the floor area;

- leveling - puttying of gaps between the boards, sealing of recessed caps of screws, nails;

- grinding - manual or orbital, belt, vibration machines.

Helpful information! If the floor plane cannot be improved using the indicated methods, instead of flooring OSB plywood it is recommended to revise the project. Dismantling a wooden floor with pouring a warm floor into a screed in this case will be cheaper, the level of the finished floor will remain unchanged.

Recommendations

At the stage of repair design, you should decide on the type of energy carrier. For example, in apartments it is prohibited to include TP circuits in central heating (fine + alteration). The purchase / installation of a boiler will be required, which will cost more than electric mats, films. In cottages, townhouses, the water TP is connected through the manifold without any problems.

When using modular polystyrene blocks of water TP, you can do without sanding the board covering. Insulation can be leveled with adhesive by applying it at 5 points (center + corners).

If TP are pre-aligned multilayer plywoodIn order for the linoleum to get a perfectly flat plane, it is very difficult to fasten this sheet material - there remains the possibility of piercing the pipe with a self-tapping screw. In addition, wood-containing materials will provide a thermal power loss of the TP of at least 30%. Therefore, it is better to align the modules with tile adhesive.

Underfloor heating installation technology

After the preparation of the base, the warm floor under the linoleum is laid on the wooden floor using various technologies. For electrical systems, it is necessary to comply with fire safety, protect users from electric shock.

When choosing water modifications, it is necessary base waterproofing film, membrane materials. In any case, it is preferable to manufacture a floating structure, separated from the walls, partitions with a damper tape around the perimeter. This gap is later disguised skirting board after facing with linoleum.

Water TP

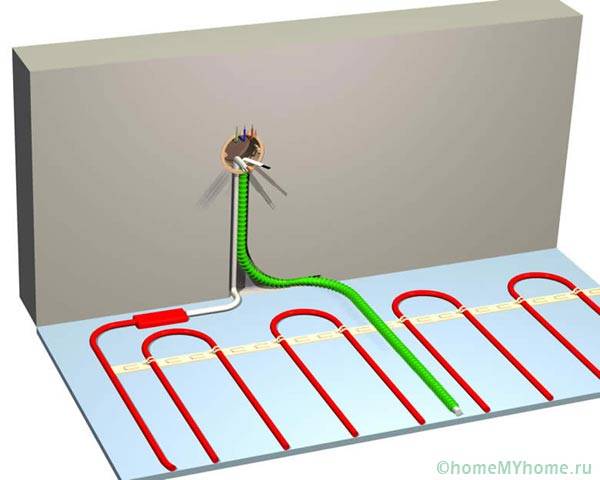

The best complete set of modular water transformer is produced by Thermotech. Concrete-free polystyrene modules have grooves that allow you to lay pipes in several ways:

- snail - for heating the central part of the room;

- double snake - maximum heating of the lower level;

- snake - uniform additional heating in the off-season.

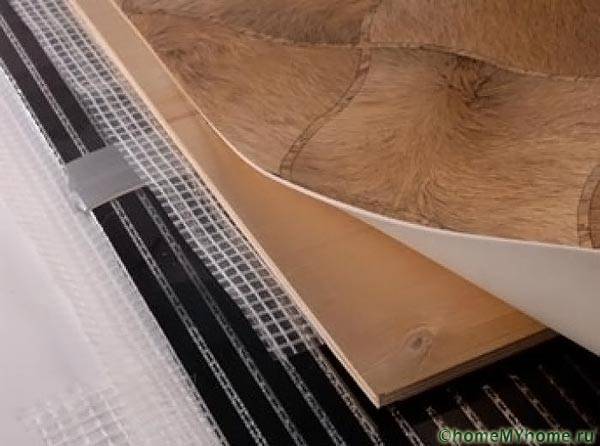

Swivel and straight channels are used as needed, unused cavities are leveled with polyurethane foam. Omega indentation aluminum plates are designed to distribute heat evenly. They fit into the slots of the modules, the pipe is mounted in them.

Before rolling out the linoleum, it is enough to additionally secure the pipes in radius roundings with double-sided tape, level the surface with a 2 - 5 cm layer of tile glue. For an economical consumption of energy carrier, polystyrene underfloor heating modules for linoleum on a wooden floor are processed from above with aluminum foil.

Helpful information! It is strongly not recommended to lay the contours of the water TP between wooden slats under the linoleum. In this case, it is impossible to lay the insulation directly under the pipes, the gaps between the slats / pipes increase, the lumber dries up over time, the linoleum loses its artistic value in the interior.

Electric TP

In apartments with centralized hot water supply, heating, electrical circuits of the TP are often used. In this case, waterproofing is not needed, but a foil backing made of polyurethane or polyethylene foam is required.

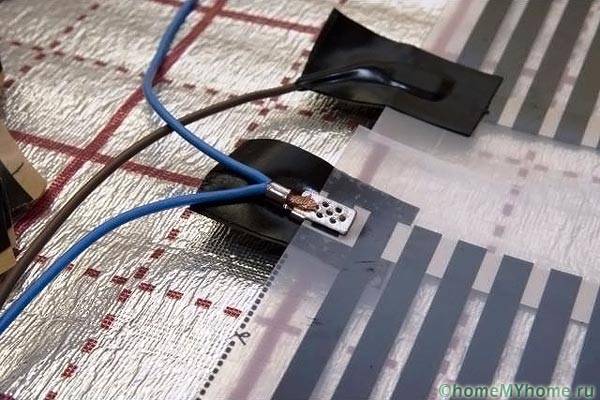

It is preferable to roll IR TP, which is supplied complete with crimp terminals, switching wires, pieces of bitumen material, in which the joints are masked. The control unit will have to be purchased separately, it is not included in the package. Installation technology consists of operations:

- substrate - covers the perimeter of the room, the rolls are joined with a special aluminum tape;

- damper - a special Uporon or Kermi tape is glued to the walls;

- thermostat - mounted on a wall, usually at a height of 0.5 m;

- the film is rolled out perpendicular to the wall on which the control unit is located, if necessary, it is extended in length, cut with an ordinary knife, the cutting places are sealed with a special material;

- electrician - current-carrying buses are crimped with terminals, connected by a wire that is fed into the control unit.

After that, warm floors in a wooden house under linoleum will significantly reduce the operating budget and increase the comfort of living.

Conclusion

Thus, laying linoleum is possible for several modifications of a warm floor on top of a plank covering along logs or a rough floor layer along beams. The choice of electrical circuits is justified in apartments, water transformer substations in cottages, where the boiler is installed by default.

Video: water heated floor on a wooden base