Three-way valve for heating with a thermostat: connection diagram, types and principle of operation

In a wide range of valves used in heating networks, there is one element that is rarely used. It is similar in shape to a tee, but the internal filling differs greatly from the latter. And its purpose is completely different. This is a 3-way valve for heating with a thermostat. The scheme of its installation, as well as the principle of operation, will be discussed in today's review.

The content of the article

- 1 Varieties and purpose of each type

- 2 The device and principle of operation of the three-way valve in the heating system

- 3 Three-way valves with actuators

- 4 Wiring diagrams of the three-way valve to the heating network

- 5 Three-way valves for heating with a fixed heating medium temperature

- 6 Rules for installing a three-way valve in a heating system

- 7 Three Way Valve Prices

- 8 Video: three-way valve for heating systems

Varieties and purpose of each type

Basically, three-way valves are divided according to the principle of operation. There are three positions:

- mixing,

- dividing,

- switching.

The first mix two streams of heat carrier with different temperatures into one, the second, on the contrary, divide one stream into two. And still others simply switch the movement of water from one direction (contour) to another. The first two varieties are similar in appearance to each other, therefore a diagram is applied to their case, which shows for what purposes the device should be used.

As for the third position, it is easy to distinguish it from the rest. He additionally has a block with which the switching takes place. A valve of this type is usually installed in a two-circuit heating systemwhen you need to redirect the stream coolant from the heating system to boiler and vice versa.

Related article:

Thermostats with air temperature sensor. A separate material provides a practical guide to the selection and installation of thermostats.

The device and principle of operation of the three-way valve in the heating system

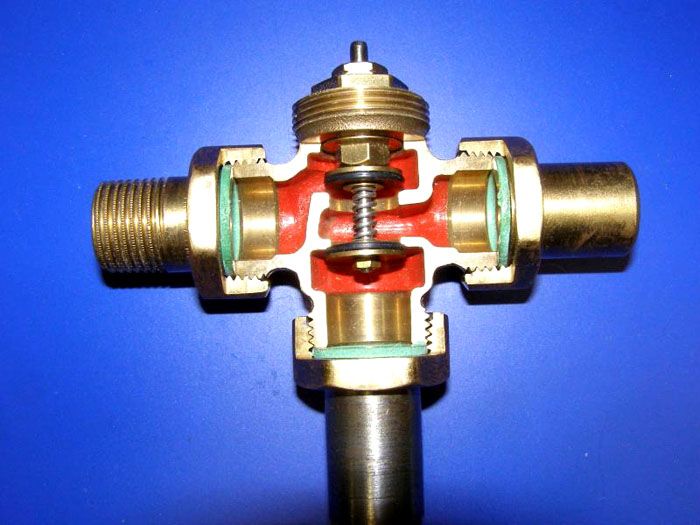

So, first of all, let's deal with the device. To make it easier to understand what is inside the valve, you need to consider the photo below, in which the device is shown in section. It consists of three nozzles (two lateral one lower), between which the mixing chamber is located. On the fourth side (top) is thermal headresponsible for controlling the temperature of the coolant.

Inside the device from thermostat comes with a spring-loaded stem with two flat round valves. Their diameter corresponds to the diameter of the nozzle seats. Instead, a single ball valve can be installed, located inside the mixing chamber between the two seats. With pressure on the stem, the valves partially cut off the supply from the lower branch pipe and open the upper one. All the same only happens the other way around if the stock rises up.

But here you need to figure out what laws the stock works, under the influence of what force it goes down or up. It's all about the thermal head itself. Inside it is a temperature sensor filled with a special liquid. It is heat sensitive. As soon as the temperature of the coolant begins to rise, the liquid expands and rises through the capillary tube into a special bellows (container), which is located in the thermal head. The reservoir itself begins to expand, thus pressing on the stem. The latter goes down and opens the lower branch pipe, from where cold water enters the three-way valve. Hot comes from the left branch pipe (see photo).

Of course, just like that, with any increase in water temperature, pressure cannot occur. For this, a temperature gradation is set on the thermal head, which is manually controlled. It is the set parameter that is the moment of pressing the rod.

So, the stem reacted to a change in the temperature of the coolant in the supply pipe, opened the lower one for cold water, and inside the valve, hot and cold media were mixed to the required temperature. That is, it turns out that the temperature of the coolant at the inlet did not change, but at the outlet it became lower.

In the event that the coolant continues to heat up, the stem can drop to the lowest possible position. That is, it will completely close the hot water supply and completely open the cold water supply. And this will continue until the coolant inside the heating system drops to the required temperature. After which the upper valve will open, it will start up hot water.

This is how a 3-way mixing control valve works. As for the dividing model, the principle of operation is practically the same, just the opposite. The coolant enters one branch pipe; inside the device body it is divided into two streams and exits through two adjacent branch pipes.

This type of shut-off valves is installed in those areas where the coolant flow must be divided into two circuits. One of them will be with a constant thermal regime, the other with a variable one. The first is the fluid flow to which quality requirements are imposed. The second with the requirements for quantity. At the same time, purely constructively, the flow with a constant hydraulic mode is never blocked, because in the design of the device, the stem length is made in such a way that the valve does not close the constant circuit.

But it must be noted that the length of the stem can be adjusted. This makes it possible to adjust the required volume of the coolant on a constant circuit. As for the variable, it can completely overlap. This is how the flow and pressure of the coolant in the heating system are regulated. As you can see, the principle of the three-way valve is quite simple. The main thing is to accurately select the type of device and install it in the required place in the circuit.

How a three-way thermostatic valve works in a "warm floor" system

To make it clear how the circuit with the valve works, you can give an example of the circulation of the coolant in the underfloor heating system. The three-way valve for underfloor heating is a mixing valve. The circulation scheme is as follows:

- hot water through the collector enters the underfloor heating system;

- it must have a certain temperature, which is monitored precisely in the process of passing through the three-way valve;

- as soon as its value exceeds the permissible value, the valve opens one of the circuits, which is connected to the heating return;

- cooled heat carrier enters inside, lowering the temperature,

- after which the mixed water enters the underfloor heating heating circuit;

- as soon as the temperature drops to the required one, the circuit with the return flow is closed by the stem inside the valve.

Three-way valves with actuators

Experts say that adjusting a three-way valve using a thermal head and a sensor is the simplest and most accurate. In addition, it does not consume electricity. That is why this type of three-way valve is popular today. But the process can be controlled in other ways. The simple one is manual. Let's face it, not the most accurate option, because the range of the stem immersion depth is set by the handle located outside the valve body.

Attention! A valve with such an adjustment is recommended to be used only in those heating systems where the temperature drops of the coolant are insignificant.

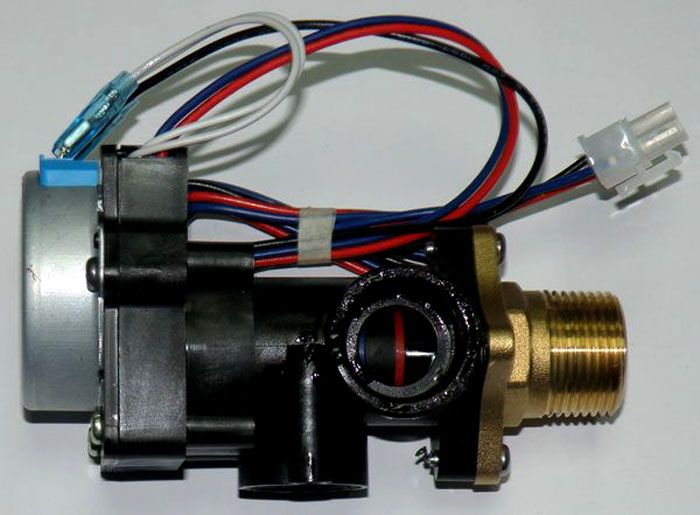

The second option is temperature control using electric drives. They receive commands from the controller.

Motorized three-way valve

Valve-mounted motors are often referred to as servo drives. In fact, these are ordinary electric motors in which the shaft does not rotate, but rotates a certain degree. It should be noted that this category includes any type of engine, for example, thermal. The main thing is to fulfill the condition of rotation, not rotation.

Manufacturers today offer two items regarding the configuration. The first is a complete package that includes a controller and a temperature sensor. It is possible to immediately adjust the device to the required temperature, as well as to the angle of rotation, for example, from 0 to 180 °. Any intermediate values are possible. The second is a separate drive with a sensor inside, to which a controller must be added as a free-standing element.

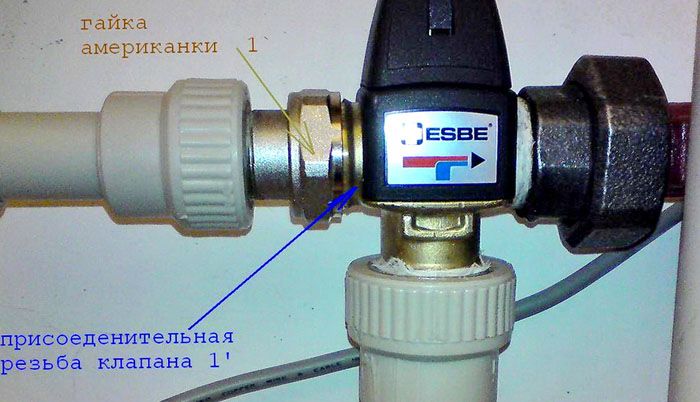

As for the controller, this is a device that solves problems of signal control. In the case of heating, it reacts to temperature changes that are signaled to it by a temperature sensor. He processes the signals and decides what to do - open the valve or close, or rather, turn clockwise or counterclockwise. Manufacturers today offer a huge range of three-way electric cranes. One of the most popular brands is ESBE (Sweden).

ESBE 3-way valve with electric drive

First of all, it must be indicated that this brand of valves has a ball with through slots inside. The latter open or close two channels, the third always remains open. Through it, the coolant enters the heating system. The degree of rotation is 90 ÷ 180 °.

In stores, the valve of this model is sold separately from the servo, therefore, before installation, they are connected together by inserting the axis (shaft) of the actuator into the top of the stem. There is a hole in it for the axle. After that, it is necessary, exactly according to the instructions attached to the device, to carry out the adjustment in terms of the temperature regime.

Today the manufacturer offers a fairly wide range of ESBE three-way valves with and without an actuator:

Other models of 3-way valves

Another well-known brand is the Navien three-way valve from a South Korean company. It should be noted that this device is an integral part of a double-circuit boiler from this manufacturer. And it is installed inside the heating equipment. Its main purpose is to separate the coolant for supply to the heating network and for hot water supply.

Attention! Navien valves cannot be repaired. The main cause of the breakdown is the gear transmission from the motor to the rod. Spare parts are not sold anywhere. In case of failure, the device must be replaced with a new one.

Danish company Danfoss is a renowned manufacturer of three-way valves. It offers four models to suit different systems:

Wiring diagrams of the three-way valve to the heating network

After all the analysis regarding the design of the valve and its principle of operation, an understanding appeared of how it can be used in various heating systems. Most often it is used in three cases.

- In the underfloor heating system, the temperature of the coolant must be within + 45 ° C. It is this mode that is supported by the device. This has already been discussed above, and it has been shown how it should work.

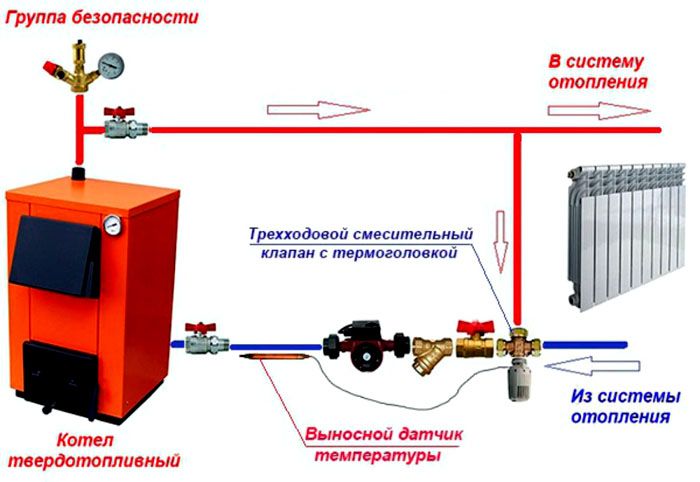

- For guard solid fuel boilers from the formation of condensate inside the furnace. This happens when relatively cold water flows through the return line to the generator heat exchanger. From this, water droplets from condensed steam are formed on the outer surfaces. This should not be allowed because condensation will shorten the life of the equipment.

- If there is a need to maintain different temperature conditions in different parts of the heating system.

The first option will not be considered, because it has already been described. As for the second case, it is necessary to take the photo below as the basis for the analysis.

In the diagram, there is a double circuit: one large one passes through the radiators, the second one short through bypass (this is a vertical red line, the beginning of which is at the top to the radiators, the end rests at the bottom against the valve). Until the boiler has warmed up, the coolant moves along a short circuit. The temperature has risen to the required value, the valve closes the bypass and opens the return flow (lower blue line).

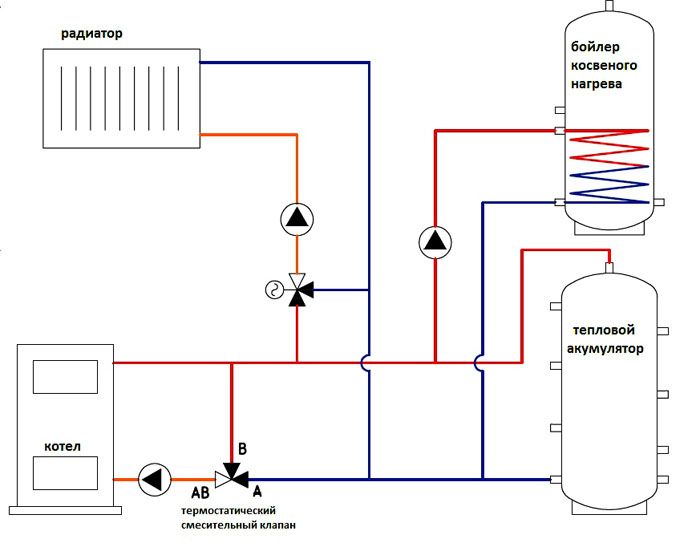

And the third position, which is based on the distribution of the coolant among consumers, in which the required temperature is not always the same. For example, an indirect heating boiler requires water with a higher temperature, for batteries with a lower temperature, and even less for heated floors.

Attention! In such a scheme, there is no need to install a control shut-off valve in front of the boiler.

The basic wiring diagram with the installation of a three-way valve should be approximately the same as shown in the photo below.

Three-way valves for heating with a fixed heating medium temperature

This is the so-called budget option. At a price it is cheaper than 30-35% of devices with drives. How is it different from everyone else. In its design there are no rods, no sensors, no thermal heads. A so-called thermostatic element is installed inside, which is set to a certain temperature of the coolant. For example, it can be either + 45 ° С or + 65 ° С. That is, the indicator can be anything depending on the requirements of the hot water consumer.

The element is selected at the factory and installed there, therefore, the valve must indicate what outlet temperature will be after it. For example, if you need a valve for a warm floor, then we choose with a temperature of + 45 ° C. The positive side of these devices is their low cost. Negative - the inability to adjust the temperature regime of the water.

Attention! If a valve of this type is installed on the bypass of a solid fuel boiler, then it is necessary to study the passport of the generator itself before purchasing. The main indicator for the valve is the water temperature in the return circuit. It is for her that the device is selected.

Rules for installing a three-way valve in a heating system

A three-way valve with or without a servo drive is easy to install with your own hands. This is just a shut-off valve, but it should be noted that it can have different fastening methods. Usually there are two of them: threaded or flanged. In the first position, the thread can be internal or external. In any case, the connection to the pipes is made by means of sealing materials such as fum tape or tow. As for the flange connection, for its tightness it is necessary to make a gasket of heat-resistant rubber or paranite.

There are two nuances regarding correct installation:

- The device is usually installed on the return loop before the circulation pump, because the outlet is always open.

- A valve must be installed in the pipeline system exactly in the direction of the arrow of the coolant movement. The latter is indicated on the body of the device.

Three Way Valve Prices

Prices for three-way valves for heating with a thermostat and an actuator vary greatly. Basically, the whole point is in which heating systems they should be installed. This applies to the pressure inside the network and the temperature of the coolant. Of course, powered devices are more expensive.

The variety of three-way valves can sometimes be confusing when choosing them. Not everyone can immediately determine which device needs to be purchased for a particular heating system.Therefore, please contact us in the comments, and our experts will answer all your questions.