Warm floor under the laminate on a wooden floor

EThe efficiency of an underfloor heating system directly depends on the technical characteristics of the base. Warm floor under a laminate on a wooden floor it is mounted differently than on a concrete base. It is known that heating systems are not cheap, and in order to dismantle or repair them, you will have to open the floor, destroying the finishing. In order not to irrevocably damage the heating system and the wooden supporting structures under it, installation should be carried out carefully and in accordance with all the rules.

The content of the article

Video: warm floor in rooms with a wooden floor

Types of warm floors

Regardless of the heat source, there are two main types of warm floors - electric and water. In the first case, an electric heating cable serves as a heat source, in the second, a liquid heat carrier circulating through the system. Water is mainly used as such a heat carrier, since it is the most mobile, which is important for circulation through thin tubes. There are options with antifreeze, but they are used in stand-alone systems where the floor loop is closed and heating is done using a heat exchanger.

Water heated floor

A warm water floor under a laminate on a wooden floor is successfully mounted, although it requires special working conditions. Water heating is a pipe system through which hot water circulates and heats the environment. Heating water in a private house occurs, as a rule, using gas boiler... Pipes for such floors can be very different - metal-plastic, copper, and also made of sewn polyethylene. The first option is the most inexpensive and convenient to install, as well as reliable in operation.

Electric underfloor heating

The floor can be heated by laying a heating cable.This cable is a multi-layer braided wire that heats up when exposed to an electromagnetic field. The heating temperature depends on the composition of the polymer from which the braid is made and is set by the manufacturer. Such warm floor it is convenient to install under a laminate on a wooden floor, they are safe and have a long service life. Its disadvantage is its high energy consumption and the appearance of a constant electromagnetic field in a residential building, the degree of its impact on human organisms is not fully understood.

Infrared floor heating

One of the newest ways to heat the floor is to use infrared sources... They are strips of polymer film coated with a thin layer of copper, silver and graphite. Under the influence of an electric current, the heating element emits infrared radiation, heating the surface above it. An important advantage of such a system is its ease of installation. The disadvantages include:

- unreliability of components - thermostat and temperature sensor;

- formation of an electromagnetic field;

- high power consumption.

Related article:

Warm floor under the tiles, which is better? From this publication you will learn about the nuances of using TP under tiles, the subtleties of installation, the pros and cons of different types of floors.

How does a wooden base differ from a concrete one?

There are significant differences between wood and concrete floors, which require a different approach to the installation of heating systems. Where the concrete base is extremely reliable, stationary, aging-free and usually perfectly leveled. Wooden floors have a number of features:

- mobility - wooden logs are subject to thermal expansion, which provokes minor, but rather noticeable displacements;

- the flooring also has the ability to "play", which makes it difficult to work and has a negative effect on the heating system;

- it is impossible to pour a concrete screed onto a wooden floor, which is an important structural element and ensures heat transfer.

Installation steps

Installation should be carried out on a prepared base, which is pre-insulated and insulated from moisture. To do this, the old coating and flooring from the boards are completely removed, only the logs remain, which must have a step of at least 60 cm, otherwise additional beams will have to be installed. The floorboards must be of the same thickness, so they are pre-treated with machine tool or replaced with a standard floorboard.

Thermal insulation

For thermal insulation, it is necessary to mount a so-called raised floor, along which an insulating layer will be arranged. For this, the lag is attached at the bottom plywood sheets, Chipboard or boards that are not suitable for other work. The resulting niches are covered with a layer of polyethylene for waterproofing, then insulation is laid in them. After that, the floor is covered with a prepared board.

Laying heating elements

Guides are needed to lay the heating elements. As such, grooves in boards or special aluminum elements - stamped plates can be used. The former are less preferable, since the process of cutting them out is complicated and laborious, and thermal conductivity of wood extremely low, that is, the floor will be slightly heated.

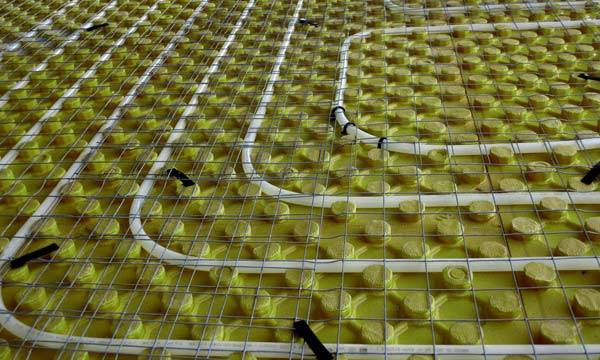

Aluminum plates will not only help guide and secure pipes, but also improve the efficiency of the system as a whole. Even when using such guides, it is worth laying a reflective layer - a thin roll foil material such as a megaflex, it will reflect heat rays upward.

The bends of pipes or electrical cables must be smooth, in either case, breaks and connections are unacceptable, that is, the pieces must necessarily be whole. A welded plaster mesh is laid on top, and on it is a substrate, on which the laminate will subsequently be laid.

Test run

Before finishing, the performance of the system must be checked over several heating-cooling cycles. In electrical systems, it is necessary to set the maximum heating mode from the beginning and see if the technical parameters are maintained, then you need to test other modes.

Water floors are checked at maximum pressure in order to exclude leaks and to see possible deformation of the pipes. Only if the system works flawlessly for 4 - 6 days, you can start finishing.

Principles of laying a floor in a private house

Warm floors in a wooden house have been laid under the laminate, now it is necessary to lay the laminate. This type of coating does not have very good thermal conductivity, however, when installing underfloor heating with a wooden base, it is the most acceptable. The base is a welded mesh on which a substrate layer is laid. Laminate boards have high strength and density, so even without a concrete screed, such a floor will be reliable and durable.

What to look for

When installing underfloor heating in wooden houses in combination with wooden flooring, you need to be prepared for the following points:

- high labor intensity of work;

- significant heat loss due to the characteristics of the material;

- a narrow choice of floor coverings - laminate, parquet or chipboard.

Video: underfloor heating device under a laminate on a wooden floor