DIY frame house: step-by-step instructions for building a structure

Prefabricated and affordable houses are by far the most promising option. In this regard, a significant part of developers are eager to learn how to make a frame house on a site with their own hands. Step-by-step instructions for them can be considered the only sure way that can bring them closer to achieving the goal.

The content of the article

- 1 Site preparation work and marking process

- 2 The most suitable types of foundations

- 3 DIY frame house: step-by-step instructions for the process of bringing a structure under the roof

- 4 Calculation of wooden floor beams online calculator

- 5 Step-by-step instructions for warming a frame house with your own hands

- 6 DIY frame house: video with step-by-step instructions in addition

Site preparation work and marking process

You should start with the preparation of the site in order to facilitate further work and achieve the highest quality markings. The building site should be 1-2 m wider than the structure itself. The list of preparatory work includes: removal of bushes, grass, trees and other interfering objects.

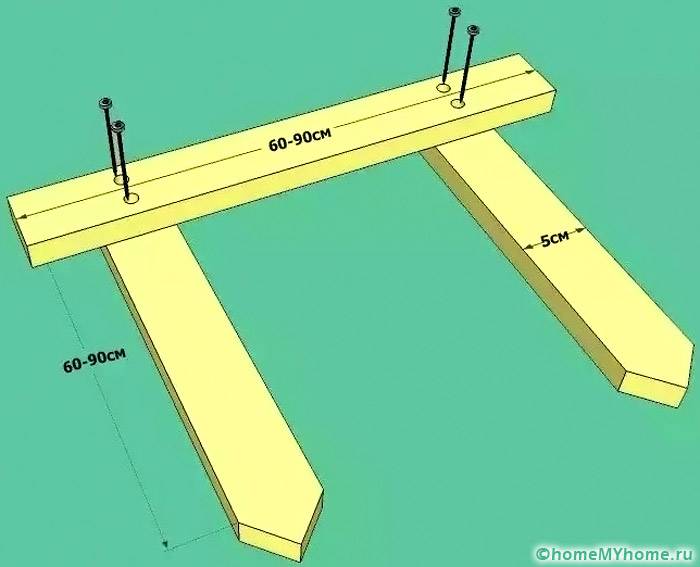

The foundation marking begins with the designation of the corners of the structure. For this, stakes are driven into the ground, which are 50x50 mm bars with a pointed edge at the bottom. The top of the posts should be at the zero mark. A right angle is usually tested by the equality of two diagonals.

The most suitable types of foundations

Before you start building a frame-panel house with your own hands, you need to decide on the type of base. Due to the lightness of such structures, there is no need for a massive foundation, but in any case it must be reliable.

Erection of a columnar foundation with your own hands for a small frame house

The most economical is the base in the form of freestanding pillars with shallow depth. For its construction, a small amount of material is required. Supports can be made either from prefabricated blocks or using concrete. They should all be at the same level.

The use of ready-made blocks greatly simplifies the construction process, so this option is the most popular. During construction, the corner supports are first installed using the building level. For this, pits are pulled out, into which sand is poured for leveling. Then intermediate racks are dug in.

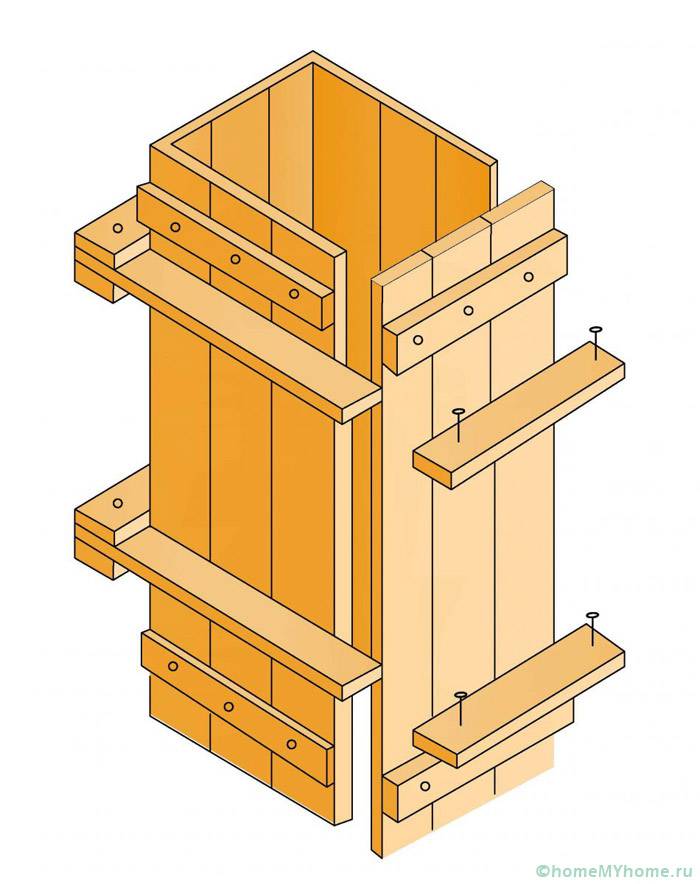

Supports are made of concrete if necessary. With this option, holes are pulled out at the locations of the racks, formwork is made around each bearing point and the building composition is poured.

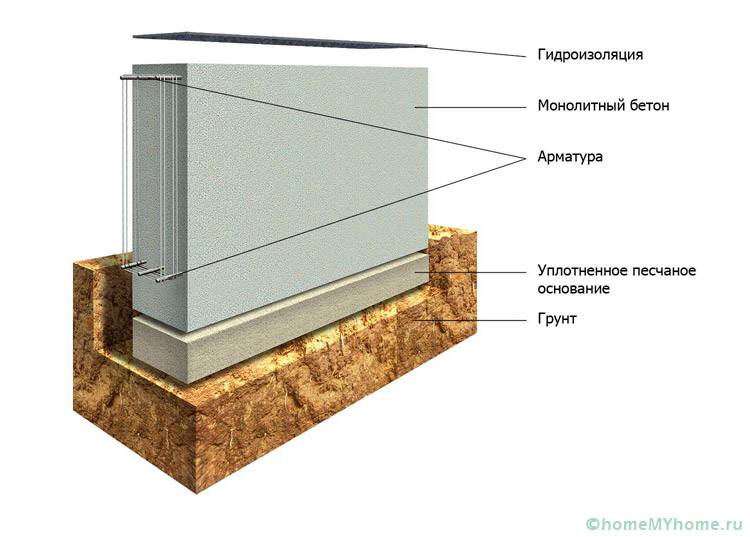

The process of erecting a strip base with shallow deepening

A fairly rational solution is strip foundation device... You can refuse strong deepening, since the frame structures do not heavily load the soil. Usually, for such structures, a network of trenches is pulled out under load-bearing walls with a depth of 20 to 60 cm.

The construction process can be divided into the following stages:

- Carrying out earthworks related to excavation around the perimeter of the building, as well as under load-bearing partitions.

- Installation of a sand cushion at the bottom of dug trenches.

- Formwork construction to create the basement of the foundation.

- Manufacturing and installation of a metal frame from reinforcement to increase the strength properties of the base.

- Pouring the concrete composition inside the formwork.

Attention! It is recommended to resume construction work only 28 days after the foundation is poured, since concrete is gaining maximum strength during this time period.

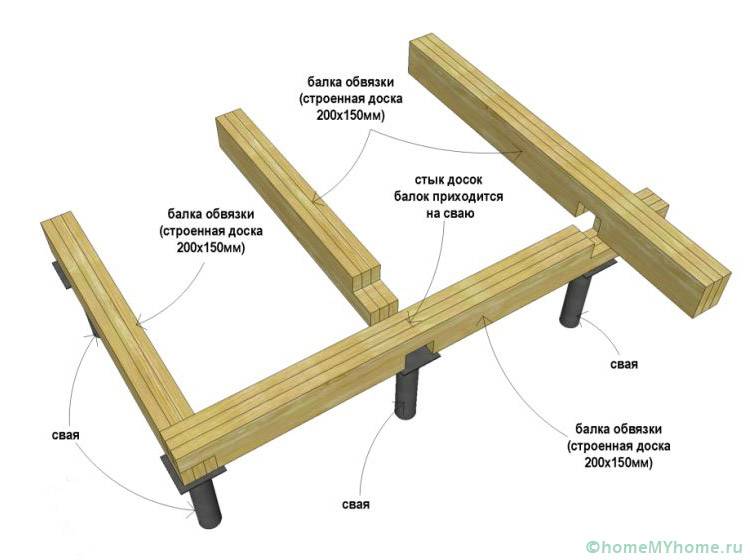

Foundation device using metal piles

In this situation, metal rods with a special plate act as supports. Most often, they are simply screwed into the ground to a certain level. Their underground part is usually deepened by at least 150 cm. The use of piles is especially important in relatively weak soil.

DIY frame house: step-by-step instructions for the process of bringing a structure under the roof

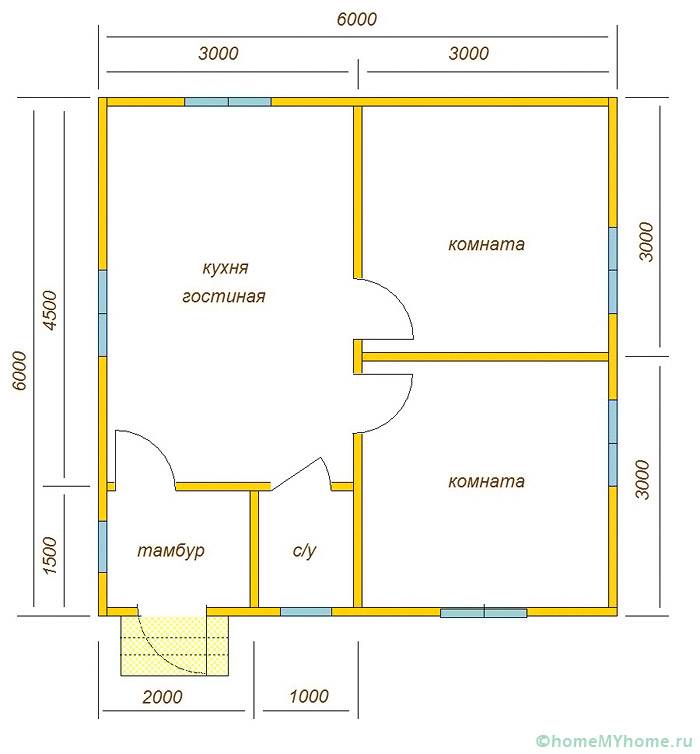

Buildings for a comfortable stay should not be too small, so it is best to build a frame house with your own hands according to step-by-step instructions 6x6 m or more. Smaller structures can be used as garden houses and summer cottages.

Related article:

Projects of frame houses with photos and prices. From this review, you will learn about the technologies for erecting frame houses, prices for some models and many myths about frame houses.

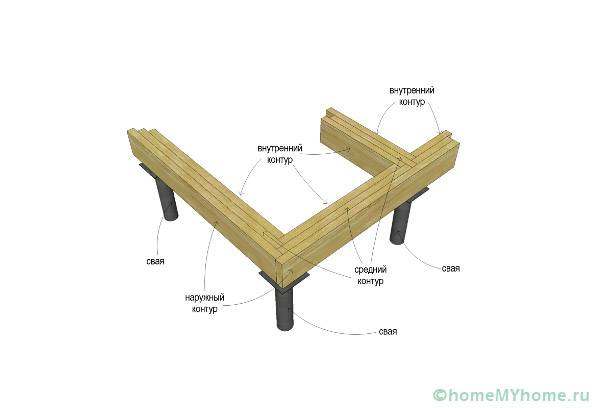

Laying waterproofing and strapping beams

On the upper side of the base, waterproofing is spread in the form of glassine or roofing material. It should be located over the entire area of the supporting parts. Bars for strapping are laid on it. In most cases, their cross section is 150x150 or 150x120 mm.

When connecting corners and internal elements, special cuts are made. Additionally, the beams can be secured with metal brackets, self-tapping screws or regular nails of suitable length.

Structural structure and outer sheathing

Although the technology of the frame construction of houses with their own hands is not so complicated, it requires certain knowledge. Particular attention is paid to the creation of the frame itself. It includes:

- support posts;

- braces;

- strapping bars (lower and upper);

- horizontal lintels of window and door openings.

Helpful information! Bars of different sections can be used as basic elements. Their choice depends on the mass of the upper part of the structure and the thickness of the walls. Lumber 150x50 or 100x50 mm are mainly used.

From the street side, the frame can be sheathed with various materials. A fairly common option is finishing with wooden clapboard. It is mandatory to put under it vapor barrier, necessary to protect the insulation from moisture.

Laying floor beams

The supporting elements of the floor are laid directly on the frame from the upper side. Often, additional strapping is made for them from lumber of a suitable section. The distance between the beams is determined by the span.

| Span size in meters | Suitable section in millimeters |

|---|---|

| 6 | 180x220 |

| 5 | 150x200 |

| 4 | 100x180 |

| 3 | 80x150 |

| 2 | 60x110 |

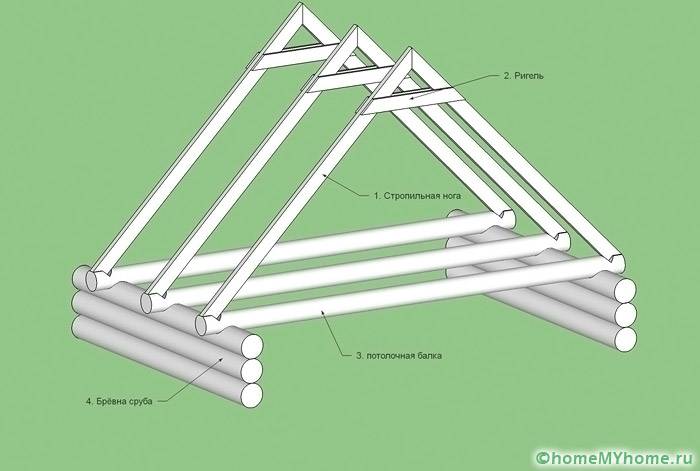

Roof erection and installation of roofing

A gable roof can be considered the easiest to construct. Usually it has two identical slopes, located at the same angle to the horizontal. Its rafters are attached to the floor beams with nails.

Crossbars are used as additional ties. They are installed at the very top and in the place of the ceiling filing. On the outside, a waterproofing membrane is laid, after which control bars are attached to the rafters. And only on them is a sheathing made of edged boards, taking into account the peculiarities of the roofing.

Step-by-step instructions for warming a frame house with your own hands

The main part of construction activities can be considered completed if it was possible to bring a frame house under the roof with our own hands. Step-by-step instructions for thermal insulation take up less volume.It is proposed to use mineral wool as a heater, since it has suitable characteristics.

- First, the distance between two posts, floor joists or rafters is measured, depending on the situation.

- The thermal insulation material is cut to size, but 1-2 cm is added to the result obtained for a snug fit to the beams.

- The prepared pieces are inserted between structural elements without gaps.

The thermal insulation must be closed with a vapor barrier membrane, after which the finishing is carried out.

DIY frame house: video with step-by-step instructions in addition

The above talked about how to make a frame house with your own hands, but visual acquaintance can be useful for a clear understanding of the process.