Professional knife sharpener - how to choose and make your own hands

When working in the kitchen, you can't do without using a knife, and it doesn't matter if the kitchen is in a small apartment or in an elite restaurant. Regardless of the type and quality of knives, sooner or later the question of sharpening them arises. Professional knife sharpener: how and what type to choose, as well as an overview of popular models, and how to make a sharpener with your own hands - the topic of this article by the homemaster.techinfolux.com/en/ editorial office.

The content of the article

- 1 Types of professional knife sharpeners

- 2 System for sharpening knives "Profile"

- 3 The best models of professional knife sharpeners

- 4 How to choose a professional knife sharpener - our editorial team's recommendations

- 5 How to make an adjustable knife sharpener

- 6 Video: Edge Pro Apex Sharpening, Corners and Other Tricks

Types of professional knife sharpeners

All existing models of sharpeners are classified according to the type of abrasive surface used and the principle of operation.

By the type of abrasive by means of which the cutting surface is sharpened, sharpeners are of the following types:

- using natural abrasives;

- with ceramic elements;

- with elements that have diamond plating.

According to the principle of operation, such devices are of mechanical and electrical types.

Professional electric knife sharpener

In the design of products of this type there is an electric motor, through which the abrasive elements are set in motion.

In electric models, diamond-coated discs, specially-coated belts, and, depending on the design of a particular model, other elements can be used as an abrasive

Depending on the design of the product, gaps can be provided on it, designed for sharpening various tools (knives, scissors, locksmith tools) at a certain sharpening angle and different standard sizes.

Some models are equipped with an abrasive rotation speed regulator, as well as elements that allow you to change the sharpening angle depending on the need.

Professional mechanical knife sharpener

When working with a mechanical sharpener, the process of sharpening the processed tool provides the physical strength of a person.

The following products can be used as a professional manual knife:

- musat - a metal rod with a notch applied to the surface or diamond dusting;

- whetstone - novaculite, water Japanese stone and other natural abrasives;

- sharpener models equipped with abrasive elements of various types and designs.

Important! When using musat and grinding stone, the correct angle of the sharpened tool must be maintained.

As a rule, mechanical sharpeners are produced with a fixed sharpening angle, which provides the processing of the cutting surface at a given angle.

System for sharpening knives "Profile"

The Profile System is a professional knife sharpener made in Russia. This device is of a mechanical type, it is intended for sharpening various cutting tools (knives, scissors, axes).

Abrasive stones ranging in size from 100 to 210 mm are used as an abrasive material in the construction of the device, which are installed on a rod and fixed to it with a spring clip.The design of the product allows you to adjust the required sharpening angle with high accuracy.During operation, the system body is fixed to a horizontal surface with a clamp.

The advantages of the Profile knife sharpening system are the following:

- high quality of the resulting sharpening of cutting surfaces;

- the ability to set the sharpening angle with a high degree of accuracy;

- mobility;

- strength and long service life.

The main disadvantage is the high cost of the product.

Related article:

Knife sharpener: types of devices, how to make it yourself, how to properly sharpen a knife at home in different ways and how to avoid common mistakes - read the publication.

The best models of professional knife sharpeners

On the domestic market of equipment and tools designed for sharpening knives, there are models of Russian and foreign companies. Among them, the most popular are products of such brands:

- Edge Pro, Gerber and Lansky (USA);

- Ganzo and Ruixin (China);

- "Wenger" (Switzerland).

Edge Pro Apex 4

Edge Pro Apex 4 Kit is a professional sharpener for knives of various designs and purposes.Distinctive features of the system are ease of use and high quality of sharpening of cutting surfaces.

Package Included:

- "Edge Pro Apex" system - 1 piece;

- water stones of different grain size - 5 pieces;

- polishing tapes of 2 types of grain size - 30 pieces;

- ceramic bar.

According to Yandex.Market, the cost of the "Edge Pro Apex 4 Kit" knife sharpening system is:

"Lansky LKCLX"

The Lansky Deluxe Knife Sharpening System is intended for professional use, but can also be used in a domestic environment.

The delivery set includes the following items:

- a vice capable of changing the angle of fixation of sharpening stones;

- whetstones of different grain size - 5 pieces;

- stone guides made of aluminum;

- case, spare bolts and sharpening oil.

The vice is made of two components, which can be fixed at a given sharpening angle; there are four of them in the system design:

- 30˚ - for knives used for cutting hard materials and products;

- 25˚ - for field and hunting knives;

- 20˚ - for kitchen knives for various purposes;

- 17˚ - for scalpels and other cutting tools requiring special precision and subtlety of the operations performed when using.

The cost of "Lansky Deluxe Knife Sharpening System" according to Yandex.Market is:

Chef`s Choice СН / 310

The model is designed for sharpening kitchen, household and tourist knives with a fixed sharpening angle of 20˚.Grinding discs with diamond dusting, driven by an electric motor with a power of 0.045 kW, are used as an abrasive.

The design of the product provides for two types of processing: intensive sharpening and polishing.

The cost of the product according to Yandex.Market is:

Work Sharp Knife & Tool Sharpener

The model is designed for sharpening knives of various types and designs, for which the product provides an adjustable guide and adjustment of the feed rate of the abrasive belt.

The machine can use belts of various grain sizes: P120 - coarse, X65 (P220) - coarse, X22 (P1000) - medium, X4 (P3000) - fine, and P6000 - extra fine.

Note! The size of the tapes used is 19 × 395 mm.

The step of adjusting the guide to create a specific sharpening angle is 1˚, and the range of change is from 15˚ to 30˚.

Feedback on Work Sharp Knife & Tool Sharpener:

Model cost according to Yandex.Market data is:

Nakatomi NEC-2000

The model is made in China, it is convenient and easy to use.The sharpening angle is fixed at 15˚, and diamond-coated discs are used as an abrasive.The product has two functions: sharpening and finishing of cutting surfaces of steel and ceramic knives.

How to choose a professional knife sharpener - our editorial team's recommendations

When choosing a professional tool for sharpening knives, the selection criteria will be the following indicators:

- Possibility of using in a long cycle and in intensive mode.

- Possibility to replace abrasive elements in case of their failure.

- The type of sharpener (mechanical, electric) depends on the mobility of the device - binding to an energy source and the possibility of using it offline.

- The ability to change the sharpening angle increases the functionality of the device and its relevance.

- The ability to perform separate sharpening and debugging is especially convenient for novice users.

Related article:

How to sharpen a ceramic knife at home with the help of musat, bar and stone, manual and electric sharpener, features of ceramic blades and sharpening options, rules for using ceramic knives.

How to make an adjustable knife sharpener

It may not be possible to purchase a factory-made tool or equipment that meets the requirements for a particular application.You have to either upgrade standard models, or make something with your own hands.

Making a do-it-yourself knife sharpener with degree adjustment is just the case when you can translate your technical knowledge and skills in working with a locksmith tool into a really useful product.

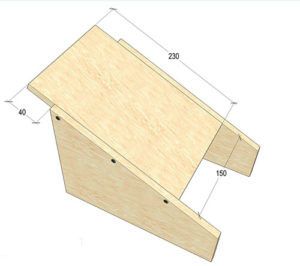

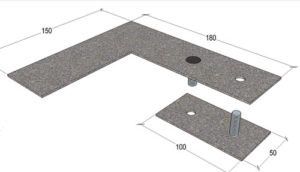

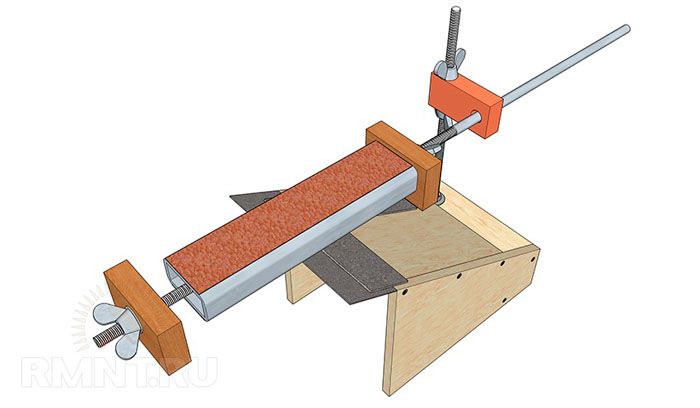

A sketch of a device for sharpening knives with an adjustable sharpening angle, available for DIY making at home

All work on the independent manufacture of such equipment can be divided into two stages: preparatory and performance of work.At the preparatory stage, a drawing or sketch of the product is drawn up, which is supposed to be manufactured, the necessary materials and tools are prepared.

To manufacture the device shown in the above figure, you will need:

- plywood with a thickness of 10 - 12 mm or chipboard;

- sheet steel 1.0 mm thick;

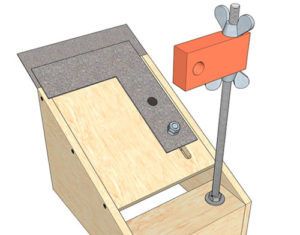

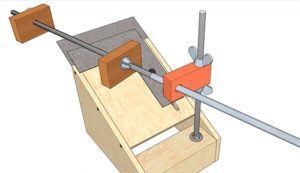

- Ø10 mm hairpin with nuts and washers;

- bolts with nuts Ø8.0 mm;

- wood block 20 × 40 × 80 mm or other hard material;

- wing nuts Ø10 mm;

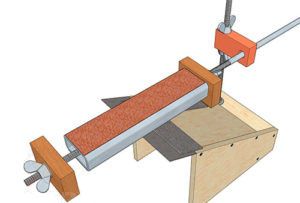

- metal profile made of steel or non-ferrous metal, with a section corresponding to the dimensions of the used sharpening stones;

- screwdriver or drill;

- a hacksaw for wood or an electric jigsaw;

- "Grinder" or hacksaw for metal.

The work is carried out in the following sequence:

This design of the sharpening device is similar to the system implemented in the machines of the American company "Edge Pro Apex".

Video: Edge Pro Apex Sharpening, Corners, and More

Having made your own hands on a knife sharpening system similar to the Edge Pro systems, you need to know how to use it. This is what the following video is about: