Knife sharpening devices - types and rules of use

Regardless of what kind of guarantee the knife manufacturer gives that during use they will not require sharpening, sooner or later this question arises before the user. It doesn't matter if it concerns kitchen utensils or camping utensils. a sharp knife is the key to success in fishing and hunting, while traveling and when cooking. Accessories for sharpening knives - types and rules of use, as well as how to make it yourself - this is the topic of today's review by the homemaster.techinfolux.com/en/ editorial office.

The simplest device for sharpening a cutting tool is a bar, and a device for its use is a fixer for the angle of the sharpened surface

The content of the article

Types of devices for sharpening knives

Sharpening devices knives can be classified according to the following indicators:

- by the type of abrasive material used - bars and whetstones;

- by the type of drive of abrasive materials - hand-held machines and devices, as well as equipped with an electric drive;

- by type of use - for home or professional use.

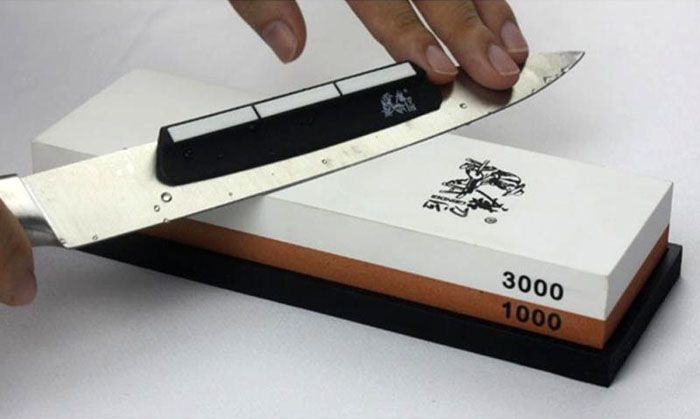

Bars and whetstones

A whetstone (whetstone) is an abrasive tool used to sharpen the cutting edges of household appliances and kitchen utensils, carpentry and metalwork tools.

The industry produces four types of stones for sharpening knives:

- natural - novaculite and Japanese water stone, are distinguished by their high price and complexity of use;

- diamond - the most popular type of product, it is distinguished by a variety of both geometric dimensions and grain size.They are distinguished by wear resistance and efficiency of use, as well as low cost;

- ceramic - a modern type of sharpening tool, distinguished by the combination of the positive qualities of natural and diamond analogues;

- artificial - the well-known types of electrocorundum or carbide, differ in low cost, but in the process of use they crumble and are not suitable for finishing the cutting edges.

The type of bar used, as well as its size and grain size, are selected by the user independently, in accordance with the need for the quality of the processing performed

Hand tools

This category includes manual machines for sharpening knives, as well as musat.

- Musat for sharpening knives.

Almost everyone knows what musat is, but many do not even suspect that this is the name of this product. The reason for this is that musat, as a rule, comes with sets of knives offered for sale through trade organizations.

Musat is a rod made of various materials, equipped with a handle and characterized by a rough drawing of the working surface.

The roughness of the drawing is the size of the notch applied to the rod, and it is this that determines the degree of roughness of the cutting surface of the knife after its processing. Musat is equipped with a rod that has a certain degree of magnetization, which ensures that metal particles formed during use get into food and kitchen utensils. Musats are classified by:

- rod shape - round and oval, flat and tetrahedral;

- materials used - ceramics and metal, diamond and mixed designs.

Each species has certain advantages and disadvantages that determine the possibilities of using the device and its purpose.

With the help of musata, you can easily adjust the knife blade right in the kitchen, practically without interrupting food

- Manual machines.

Household manual knife sharpening machines differ in their design, but in any of them, a bar or a whetstone acts as the main element. The action of the abrasive tool on the cutting surface is carried out using the forces applied by the user. The main task performed by the manual machine is to create and maintain the optimal angle of sharpening of the cutting edges for the entire period of work, which is achieved by rigidly fixing the knife in a given plane. The industry produces various models of such equipment, differing in the size and method of attaching abrasives and processed knives, as well as the materials used and cost.

Manual knife sharpeners can be used not only as household equipment, they are successfully used by professionals as well. The only difference between models for household and professional use is their cost, which depends on the type of abrasive materials that guarantee the quality and speed of sharpening.

Professional and household knife sharpeners equipped with an electric drive

The presence of an electric drive greatly simplifies the process of using devices for sharpening knives, this applies to both models for home use and professional use.

Distinctive features of models for various types of use are:

- the value of electrical power - it is higher for a professional tool, and less for household models;

- period of use - determines the possibility of machine operation without stopping (PV-inclusion);

- overall dimensions and method of fastening (installation) on the working surface of a table or other piece of furniture;

- the type and size of abrasive available for use on a particular model;

- functionality - the ability to sharpen knives of various types (kitchen, from cutting mechanisms and devices, scissors, etc.).

Household electric sharpeners do not take up much space and are very functional, because in their design, as a rule, various fixed sharpening angles are provided for different types of knives and other cutting tools (scissors, screwdrivers, etc.). The ability to quickly and efficiently sharpen the cutting edges of knives is very important for catering establishments, where the speed and quality of cooking depends on sharpening. Professional machines for sharpening knives are functional devices equipped with high-quality abrasive tools that allow you to perform not only rough sharpening, but also fine-tuning the cutting edges of knives for various purposes.

Electric sharpener "Work Sharp Ken Onion Edition" can be used by professionals and in an ordinary apartment

Professional models, in addition, as a rule, have several modes of operation that allow sharpening with different efficiency required for knives made from different metals or ceramics.

How to properly sharpen a knife at home

Everyone knows that a knife must be sharp, and for this it needs to be sharpened, but how to do it correctly is often not known to every user. It should be noted right away that for the correct performance of the work it is necessary:

- Know the sharpening angles for each type of knives and other cutting tools.

- Be able to work on various equipment or using available accessories.

Sharpening angle of knives for various purposes

For knives used for different purposes, the sharpening angles of the cutting edges are different, due to their purpose and nature of use.

This value is for:

- table knives - 55-60˚, because ready-made dishes are soft enough and cut easily, moreover, with a lower sharpening angle, there is a possibility of damage to the dishes during a meal;

- hunting and folding models - 40−45˚, which is explained by their versatility;

- kitchen knives - 30−35˚;

- used for professional cutting of vegetables - 35˚;

- used for professional cutting and deboning of meat - 25-30˚;

- used for professional cutting of fish - 25˚.

Some types of knives are sharpened with other sharpening angles, such as those intended for slicing bread (the angle is 15˚), but this is a narrowly targeted use, in which sharpening must be performed quite often, because with a decrease in this indicator, the resistance of the cutting edges decreases.

How to sharpen a knife at home with a bar

In order to properly sharpen a knife using a bar, you must follow several rules for performing work:

- it is necessary to choose the optimal sharpening angle corresponding to the purpose of the knife;

- the blade should be located in relation to the plane of the bar strictly in the specified parameters of the sharpening angle for the entire period of work;

- sharp and abrupt movements should not be allowed, they must be smooth and sliding;

- when performing work, the bar should be moistened abundantly with water diluted with soap or detergent.

How to sharpen with musat

The process of sharpening a knife using musat is shown in the following figure.

The work is done as follows:

- musat is installed on a flat surface strictly in a vertical plane;

- the upper part of the device is aligned with the sharpened edge of the knife near its handle, after which the knife moves along the musat rod in an arcuate motion directed from top to bottom;

- the movements are repeated several times on both edges of the knife.

I would like to note that experienced users can perform this operation on the weight, without rigid fixation of the rod of the device used.

How to sharpen a knife on an electric sharpener

When using models equipped with an electric drive, the basic requirements for performing work to ensure correct sharpening are the same as when using a stone or a whetstone.

Sharpening of cutting edges on a grinding machine using a device that provides the required sharpening angle

But, besides this, there are additional requirements, which can be formulated as follows:

- it is not the abrasive that should be moistened with water, but the surface of the knife being processed, which is explained by the fact that water does not remain on the rapidly rotating wheel;

- overheating of the blade must not be allowed, which can lead to its damage, which occurs when the machined edges are strongly pressed against the abrasive surface;

- for rigid fixation of the sharpening angle, additional devices can be used that are installed rigidly to the body of the grinding machine or are in the hands of the user;

- when working on industrial grinding machines, it is necessary to use personal protective equipment, such as gloves and goggles.

In the case of using small devices intended for home use, the main requirement for sharpening is the operation time, all the rest (fixing the sharpening angle, protection, etc.) the machine performs itself, according to its design.

Typical mistakes when doing work with your own hands

When sharpening knives on their own, many users make typical mistakes, which can be summarized as follows:

- Creating the wrong sharpening angle prevents the knife from being used for its intended purpose or limits its functionality.

- Excessive pressure when working on electric models or the wrong direction and nature of the movements when using a bar or grindstone contribute to damage to the surface of the knife, destruction of its edge.

- Sharpening the cutting surface without first cleaning it from dirt and foreign matter leads to blurring of the abrasive and its damage.

- Using only one musat when sharpening cutting edges. This device is intended only for finishing or straightening the knife blades; it is not intended for main sharpening.

- Failure to complete the sharpening operation again leads to a rapid blunting of the cutting edges.

- Use of an abrasive (stone or whetstone) of only one grain size.

Making a machine for sharpening knives with your own hands

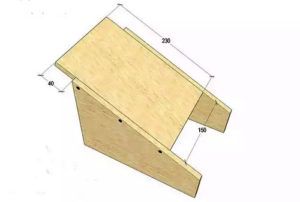

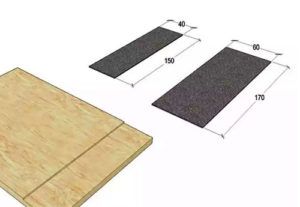

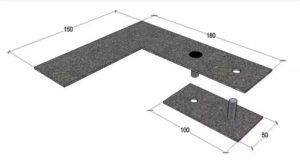

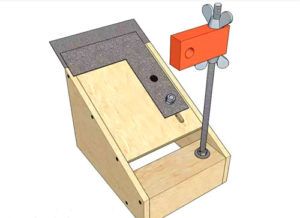

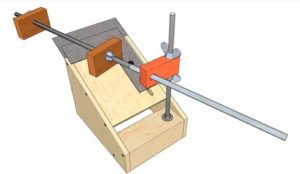

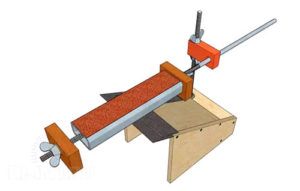

Although it is now possible to easily buy the necessary tools and equipment for sharpening knives and other cutting tools, nevertheless, handicraft citizens continue to make knife-cutters with their own hands in their free time. When making a knife sharpener with your own hands, you need to decide on its type (manual or electric) and the type of abrasive materials used (bar, circle, sanding belt), as well as the materials available that will go to make the body of the assembled device, its frame. Consider a manual sharpener using an abrasive bar and plywood as the frame of the structure. The appearance of the assembled device is shown in the following figure.

To manufacture such a machine, you will need the following materials and tools:

- sheet plywood 10–12 mm thick or chipboard, it is possible from old cabinet furniture;

- metal hairpin with a diameter of 10–12 mm;

- sheet steel 1 mm thick;

- fastening screws or nuts with washers, corresponding to the diameter of the stud used;

- bar 25-30 mm thick - for the manufacture of abrasive bar stops;

- profile metal pipe with a section corresponding to the dimensions of the bar;

- abrasive bar;

- hacksaw for metal and wood or their electrical counterparts (jigsaw, grinder);

- electric drill or screwdriver.

Manufacturing works are carried out as follows.

On the market of goods intended for sharpening knives and other cutting tools, there is a wide selection of models that differ in design and purpose, type of use and equipment, which allows you to choose a device in accordance with the selection criteria and financial capabilities of the user. When choosing a specific device or model of grinding equipment, sales consultants in trade organizations will provide assistance, and how to use it correctly can be found on the Internet.

You can learn how to sharpen knives with a bar correctly by watching the video below.