How to choose and use a soldering iron for microcircuits

Electronic microcircuits are installed not only in televisions and music centers. They are used for door locks and refrigerators, various drives and lighting devices. They perform the functions of microprocessors, memory, power supplies, and other devices. Current trends indicate a gradual expansion of their scope. Therefore, a soldering iron for microcircuits is useful for equipping a modern personal workshop. With its help, you can quickly make repairs or upgrades, without resorting to the services of expensive specialists and other unnecessary costs.

In the large assortment of offers from specialized stores, it is not difficult to find tools for successfully solving specific problems

The content of the article

- 1 Determination of criteria for choosing a high-quality soldering iron for microcircuits

- 1.1 Do I need to buy a hair dryer for soldering microcircuits: general requirements for tools

- 1.2 How to solder a microcircuit from a board with a soldering iron: application and features of technological operations

- 1.3 Which soldering iron is better to choose: an overview of different models and clarification of individual requirements

- 2 What the modern market offers

- 3 Additional tips and conclusions

- 4 Video: Goot CS Series Soldering Irons for Precision Electronics

Determination of criteria for choosing a high-quality soldering iron for microcircuits

In order not to be mistaken with the purchase of tools, it is necessary to clarify the scope and parameters of future work. Consideration should be given to the characteristics of the electronic components, the conditions in the home workshop and personal preference. A market overview with the study of new products offered by modern manufacturing enterprises will be useful. Some devices for performing certain operations can be made with your own hands. Such an integrated approach will help you choose the optimal equipment configuration.

Do I need to buy a hair dryer for soldering microcircuits: general requirements for tools

The first criterion that experts recommend to consider is power. An electric soldering iron for soldering chips consumes from 3 to 15 watts. The group from 15 to 50 W includes universal tools. They are useful for dismantling and installing diodes, transistors, resistors, and other individual electronic components. If you intend to work with thick conductors (more than 1.5 mm in diameter), you should purchase a heating device with a power of 75-100 W.

Similar soldering irons with a power of up to 250 W are used for tinning dishes, connecting copper pipes

After determining with a suitable power, you need to deal with the working nozzle. Without experience, it is easier to work with a straight blade.

Different tools may be needed to accurately perform individual operations. They can be purchased (created by yourself) later, as you master the working operations.

Specialized nozzle for soldering microcircuits. Such devices are created taking into account the size and other parameters of certain electronic components.

Natural wood has low thermal conductivity, so some craftsmen prefer this option. However, in modern models, plastic is supplemented with rubber pads, which provide a secure grip. The thickening at the front improves safety. Convenient placement of regulators facilitates operation. In any case, personal physiological characteristics must be taken into account.

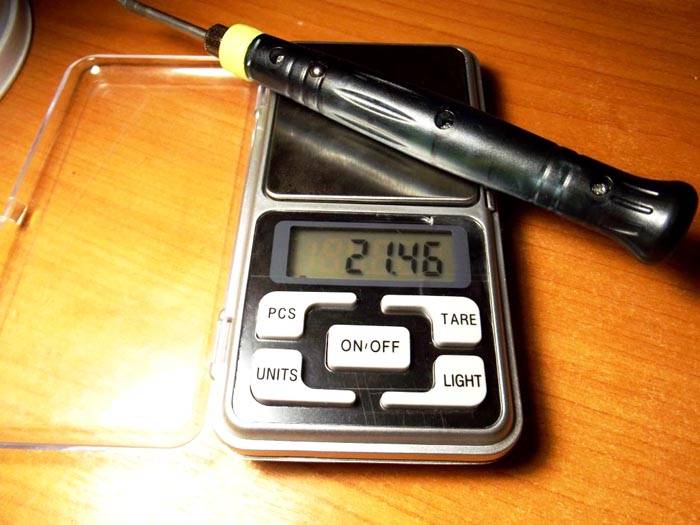

With a lightweight soldering iron, large volumes of work can be performed without unnecessary physical effort

Such a tool is not used for working with microcircuits. Its main advantage, autonomy, is not a significant factor in this case. Such products generate excessive heat that can damage electronic components. As a rule, they are used for electrical work.

This can be useful in practice. But it should be noted that such products are heavier than conventional models. You should also check if the soldering iron is available with a wide platform for simultaneous soldering of several microcircuit legs.

Such a tool creates volumetric heat, which is used to solder various electronic devices. Care should be taken not to damage them by excessive temperature.

How to solder a microcircuit from a board with a soldering iron: application and features of technological operations

When working with certain electronic components, take into account the installation rules, which are given in the manufacturer's instructions. They contain information about temperature conditions. To prevent overheating, reduce the exposure time, choose suitable types of solder.

Table 1. Types of solder

| Digital designation of the composition of the POS | Melting point, ° C |

|---|---|

| 60 | 190 |

| 50, 90 | 222 |

| 40 | 235 |

| 30 | 256 |

| 18 | 277 |

Soldering Station. In this specialized set of equipment, the control unit maintains the temperature automatically set by the user.

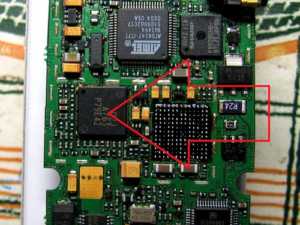

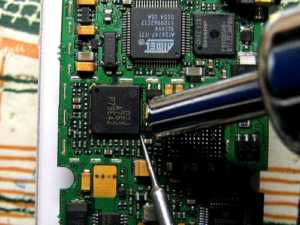

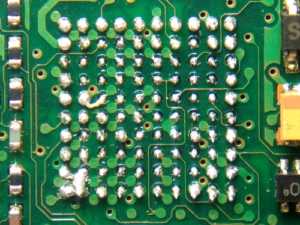

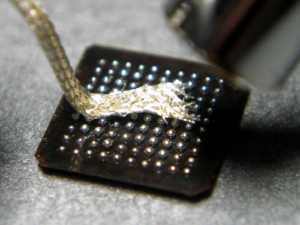

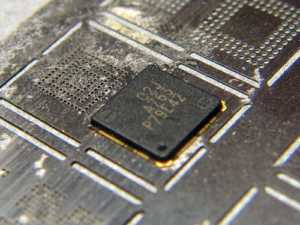

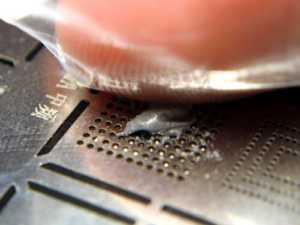

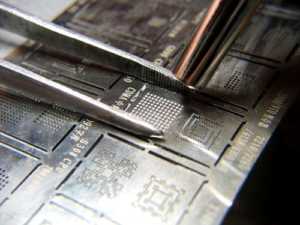

What is needed for soldering microcircuits will be easier to find out after studying the technological process. The following describes the sequence of actions when working with components of the BGA category. In these housings, the terminals are installed at the bottom of the housing. This engineering solution makes it possible to reduce the size of products, but complicates their installation and dismantling on the board.

Table 2. How to solder the microcircuit from the board with a soldering iron

Which soldering iron is better to choose: an overview of different models and clarification of individual requirements

The set of equipment discussed in the previous section of the article has advanced functionality. It allows you to perform professional soldering. But it should be borne in mind that such kits are expensive.

However, even a beginner should not purchase the simplest models if they intend to work with microcircuits. First, temperature control must be ensured. The electrical isolation from the standard 220 V power supply is also useful. It will increase the level of safety and at the same time prevent damage to the electronic components on the board. Similar functions are performed by grounding.

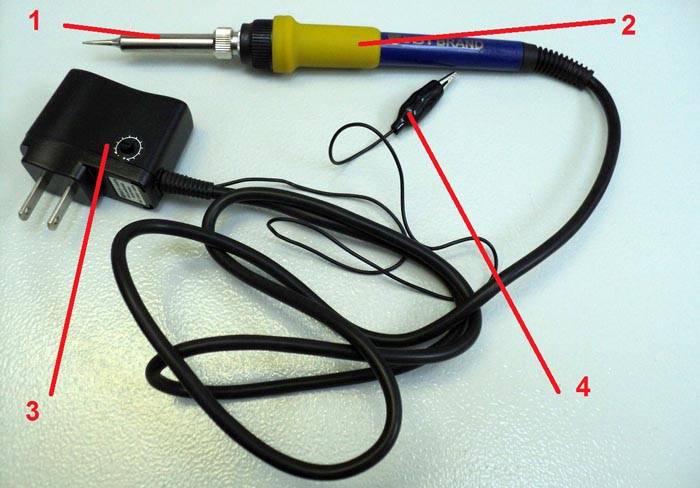

Below is an example of a suitable set. It attracts with a democratic price and good technical characteristics.

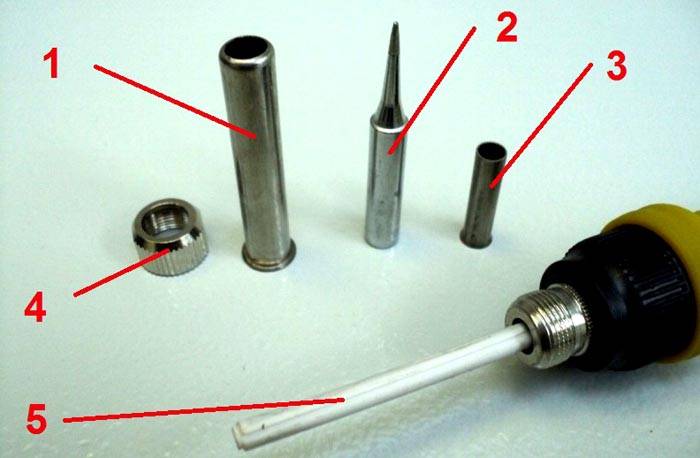

The kit contains all the necessary components:

- Soldering iron (2) with soft pad on the handle. This element improves the insulating properties, facilitates a secure grip.

- Removable tip (1) with thread lock.

- Power supply unit (3) with built-in heating controller.

- Grounding device (4).

With this example, you can examine in detail the positive and negative nuances. The knowledge gained will be useful for an objective assessment of the current offers on the domestic market.

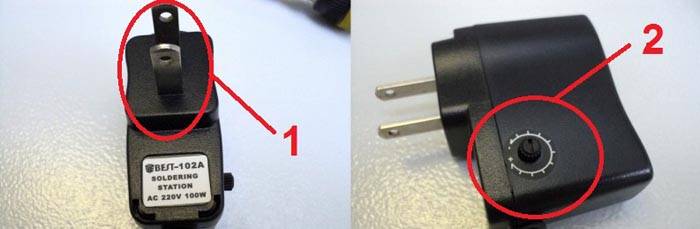

For such a plug (1), you need to purchase an adapter for a European standard outlet. Lack of marking (2) makes it difficult to set the desired temperature

This model has a ceramic element (5). It provides uniform heating and good efficiency. But its strength is less in comparison with the nichrome analogue. However, there is reliable protection (1, 3) from mechanical damage. The knurled nut (4) is convenient for attaching and changing the tip (2). This mount is designed for long-term use.

These add-ons simplify individual work steps.

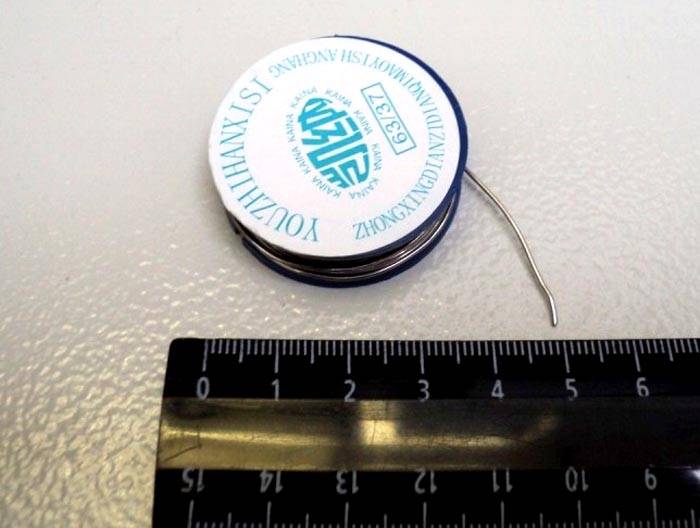

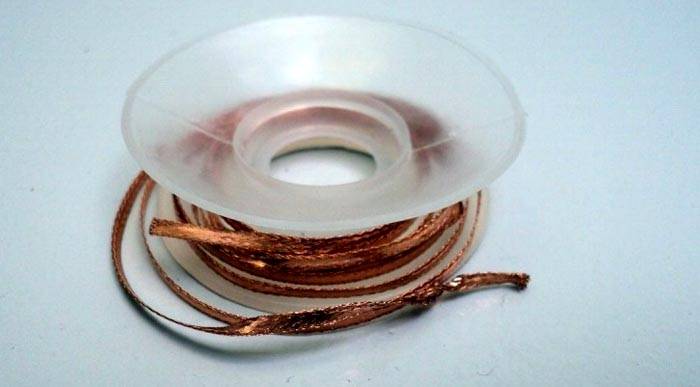

To remove excess solder from the board and the legs of the parts, you can purchase a braid on a reel

What the modern market offers

When choosing soldering irons for home, the data from the following table will come in handy. The assessment should be made based on the above information. It should be noted that some universal models can be used for soldering different parts.

Table 3. Soldering iron models

Additional tips and conclusions

It is not difficult to buy an electric soldering iron for microcircuits using this article. But we must not forget about the correct equipment of the workplace:

- The table top must be resistant to high temperatures.

- Good lighting will help you perform the most complex operations accurately.

- Good ventilation is useful for removing vapors.

- It is convenient to store small electronic components and consumables in boxes of suitable sizes.

- Large instruments are placed in lockers.

Miniature parts are easier to work with with a microscope and a magnified image on a computer screen

Video: nGoot CS series ironing irons for precision electronics