A gun for polyurethane foam: the nuances of selection and an overview of popular models

To one degree or another, a modern person in his life is faced with the use of various sealants. This may be due to plumbing work or car maintenance, sealing of the interface of various structures or pieces of furniture. One of the types of sealants sold in aerosol containers and used for construction and installation work is polyurethane foam. A gun for polyurethane foam - types and scope, device and technical characteristics, as well as how to choose and use it correctly - we will tell you about all this in this review by the homemaster.techinfolux.com/en/ edition.

The content of the article

- 1 Scope and principle of operation

- 2 Sectional drawing of a polyurethane foam gun

- 3 Types of polyurethane foam guns

- 4 Main technical characteristics

- 5 How to choose a gun for polyurethane foam

- 6 Professional models of guns for polyurethane foam

- 7 Household foam guns

- 8 How to use a foam gun correctly

- 9 Video: how to clean a foam gun

Scope and principle of operation

The need to use polyurethane foam, respectively, and the use of a pistol serving to spray it, arises when performing various types of repair and construction work, such as:

- sealing joints of various building structures, pieces of furniture or technical devices;

- warming of structural elements of buildings and structures at the stage of their installation (windows, doors, roofing, enclosing structures, etc.);

- installation work related to gluing various materials to each other (fixing foam and other insulation to the building base);

- works related to sound and noise insulation of premises;

- filling voids of different origins and cracks in elements of various structures.

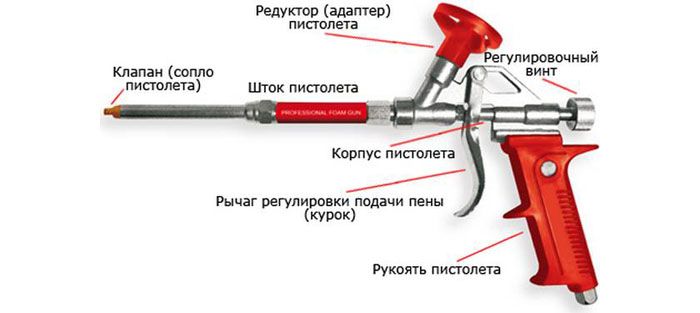

The principle of operation of this type of pistol is based on the fact that a cylinder with polyurethane foam is installed in the adapter of the device, which is in it under pressure in an aerosol state.When the trigger is pressed, the valve mounted on the cylinder opens, and the polyurethane foam begins to move along the barrel of the gun through the fitting installed at its end. The amount and rate of aerosol supply is regulated by a special lock (adjusting screw).

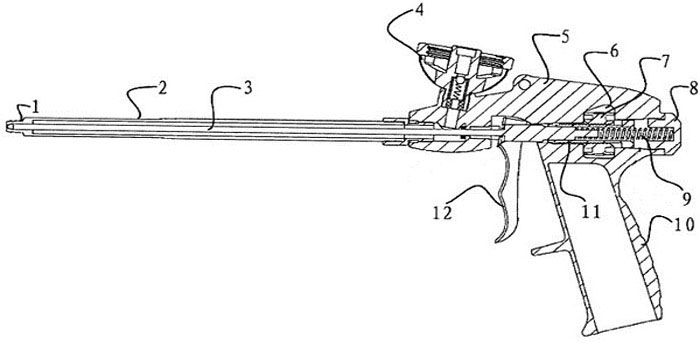

Sectional drawing of a polyurethane foam gun

The main structural elements of the gun for polyurethane foam are the adapter (reducer), through which the cylinder is installed, and the aerosol supply mechanism, placed in a single housing. All structural elements of such a device are indicated in the section shown in the following figure.

This figure shows the following structural elements, namely:

- 1 - nozzle (fitting);

- 2 - trunk;

- 3 - needle rod;

- 4 - adapter;

- 5 - case;

- 6 - through hole;

- 7 - liners;

- 8 - lock nut (adjusting screw);

- 9 - spring;

- 10 - handle;

- 11 - fixing sleeve;

- 12 - trigger.

Note! The barrel and the handle are attached to the gun body by means of a threaded connection. The needle bar and trigger are mechanically interconnected, and the foam flow is regulated by the presence of a pressure spring, a liner and a retainer nut. Rotation of the liner drives the sleeve moving in the axial direction, which, in turn, limits the movement of the needle rod and, as a consequence, the amount of foam supplied to the nozzle.

Types of polyurethane foam guns

Polyurethane foam guns are of household and professional types, which determines the nature of their use. Professional models can be disassembled and cleaned of the main structural elements, after which the gun can be used again. Household models are usually non-separable, which makes them difficult to clean and reuse.

Main technical characteristics

When choosing a gun model for polyurethane foam, of course, you should know what technical characteristics you should pay special attention to, because the convenience of use and the period of operation of such devices depends on this. The main technical characteristics for such a tool are:

- the ability to maintain tightness, depending on the type of valves used;

- material used in the manufacture of the body and the main structural elements.

The ability to ensure tightness determines the quality of the gun, expressed in the accuracy of dispensing and preventing the foam from drying out in the gun. In the manufacture of tools, various types of plastic and metal are used. Models for professional use are made of impact-resistant plastic and metal.

Important! Guns made of metal are easy to maintain, reliable and have a long service life.

How to choose a gun for polyurethane foam

If it is necessary to perform work using polyurethane foam, the question arises of purchasing an assembly gun for spraying it.

In this case, the criteria for choosing such a tool will be such parameters as:

- Purpose and nature of use - for a single use, you should not buy a professional tool, and to perform a large amount of work, a household model will not cope with the task.

- Specifications (valve tightness and materials used).

- The ability to disassemble the structure for cleaning the main elements of the device.

- The availability of spare parts depends on the reliability of the manufacturer and its relevance.

Professional models of guns for polyurethane foam

On the domestic market of professional tools, there are models of spray guns made by foreign and Russian manufacturers.The most popular among them are products of such companies as Kraftool GmBH (Germany) and Matrix (China-Germany), Hilti (Liechtenstein), as well as FINCH INDUSTRIAL TOOLS CANADA INC. (Canada) and "Zubr" (Russia).

"Kraftool Celnometal"

The model is distinguished by ease of maintenance, functionality and reliability, which is confirmed by reviews of real users.

| Housing | Material | Weight, kg |

|---|---|---|

| Collapsible | Metal | 0,82 |

In addition, the model has a Teflon-coated nozzle and sealant flow regulator, which greatly simplifies tool maintenance.

Review of the "Kraftool Celnometal" model:

"Hilti CF DS1"

The distinctive features of the model are low weight and high quality workmanship.

| Housing | Material | Weight, kg |

|---|---|---|

| Not collapsible | Reinforced plastic | 0,4 |

The presence of a thin nose and the ability to use in different planes make this model one of the best in the segment of professional tools.

Feedback on the "Hilti CF DS1" model:

"Matrix 88669"

The model is popular due to its reliability and trouble-free operation.

The body is covered with a Teflon coating, which greatly facilitates the cleaning of the gun, and the presence of two restrictive handles makes the use safe from injury.

| Housing | Material | Weight, kg |

|---|---|---|

| Collapsible | Metal | 0,55 |

"FIT 14270"

A distinctive feature of this model is the high quality of the materials used and the assembly performed. This gun can be used by both professionals and for personal use, and the presence of special attachments expands its functionality.

| Housing | Material | Weight, kg |

|---|---|---|

| Collapsible | Metal and plastic | 0,5 |

"Bison Turbo 4-06877"

The model has an affordable cost and can be used by amateurs and professionals. The holder for cylinders is treated with a special coating, and the polished inner surface of the barrel facilitates the process of servicing the product.

| Housing | Material | Weight, kg |

|---|---|---|

| Not collapsible | Metal and plastic | 0,61 |

Household foam guns

Among the models designed for one-time work, and not professional use, the most popular are models from companies such as "P.I.T." (Russia) and "Biber" (Germany), "STAYER" and "BLAST" (China).

"Biber Master 60111"

The model is distinguished by its affordable cost and, at the same time, high technical performance, which allows the pistol to be used even under intensive operating conditions.

| Housing | Material | Weight, kg |

|---|---|---|

| Collapsible | Plastic and metal | 0,67 |

P.I.T. Р7000003 "

The assembly gun from Chinese manufacturers is the best product for performing one-time work. In the model, all elements are made of plastic, with the exception of the barrel and the valve, which made it possible to reduce the cost of the product and reduce its weight.

| Housing | Material | Weight, kg |

|---|---|---|

| Not collapsible | Plastic | 0,4 |

Review of the model "P.I.T. Р7000003 ":

"Stayer Master EconoMax 06861"

This model is distinguished by unpretentiousness in use, due to its simplicity, as well as the ability to long-term use, because only high-quality materials are used in the manufacture.

| Housing | Material | Weight, kg |

|---|---|---|

| Not collapsible | Plastic and metal | 0,41 |

Feedback on the Stayer Master EconoMax 06861 model:

"Blast Extra Lite 590024"

The model is one of the cheapest of all offered on the domestic market.

In addition, due to the maximum possible use of plastic, the product turned out to be the lightest in comparison with similar analogues.

| Housing | Material | Weight, kg |

|---|---|---|

| Not collapsible | Plastic | 0,15 |

Review of the Blast Extra Lite 590024 model:

How to use a foam gun correctly

A gun for polyurethane foam is a fairly easy-to-use tool, therefore, for its correct use, you need to know a few basic rules:

- the cylinder with polyurethane foam should be on top, if possible in a vertical plane, because otherwise, the gas may escape outside, or its pressure will not be enough to spray the contents of the cylinder;

- before use and with a long cycle of work, the foam canister must be shaken a certain number of times;

- before installing the can, the adjusting screw should be closed all the way, and after installation, open it ½ turn and press the trigger, thereby checking its performance;

- during operation, the feed rate of the sealant is set by the adjusting screw;

- an open cylinder must not be disconnected from the gun until the foam is completely consumed, otherwise it will dry out;

- after using the spray can, the gun should be cleaned.

You can learn how to use the foam gun by watching the following video.

Video: how to clean a foam gun

It is quite simple to clean the gun from polyurethane foam, you just need to know some of the nuances of the work. The following video will tell you how to clean the gun from polyurethane foam.