Ideas proven in practice, or How to make a grinder with your own hands according to dimensional drawings

A household tool is a necessary thing. A home craftsman cannot do without a drill, grinder, screwdriver and many other devices necessary for repair and construction. But not everyone has the opportunity to endlessly buy mechanisms if they are needed only for some temporary or urgent work. There is a lot of information on the network about homemade products that can be made from scrap material. Today, the homemaster.techinfolux.com/en/ editorial board has prepared for you all the most useful information on how to make a grinder with your own hands. Drawings with dimensions, options for using different engines and practical advice from professionals in our material.

The content of the article

- 1 What is a grinder and what is it for

- 2 Schematic diagram of the grinder design and the principle of its operation

- 3 An example of a well thought-out mechanism is a grinder from Chapay

- 4 Video and photo recommendations for making a do-it-yourself grinder at home

- 4.1 What to make a drive for a grinder

- 4.2 Is it worth making a homemade grinder with a washing machine engine

- 4.3 Step-by-step recommendations on how to make a grinder from a drill

- 4.4 Do-it-yourself grinder from a grinder: drawings and ready-made nozzles

- 4.5 How to make a grinder from a grinder with your own hands: video instructions

- 4.6 How to make a grinder with your own hands: drawings with dimensions from different authors

- 4.7 How to glue a tape for a grinder with your own hands and special requirements for it

- 4.8 How and what to make do-it-yourself rollers for a grinder

- 4.9 How to make a pulley for a grinder with your own hands: video recommendations

- 4.10 Rotary table for grinder

- 5 Prices for household and professional grinders

What is a grinder and what is it for

The word "Grinder" is of English origin and literally reads like a grinder. In technical terms, this term is used to refer to a grinding device. So one could just call this unit a grinder, but then there would be a confusion with manual grinders that have a slightly different device. Grinder is a stationary unit with an electric drive.

The rest of its design is very similar to a hand sander and is based on a rotating pulley with a strip of abrasive paper

What is a grinder used for? First of all, it is a mechanism for sharpening household cutting tools.With a certain skill, you can perfectly sharpen kitchen knives or scissors, wood cutters. In addition, with the help of a stationary machine, craftsmen grind wooden parts, stone and metal parts. A grinder will help align the edge of glass, fiberboard or MDF.

Professional machines are not cheap - from 30,000 rubles, so the question of how to make a homemade grinder with your own hands is hotly discussed in many forums.

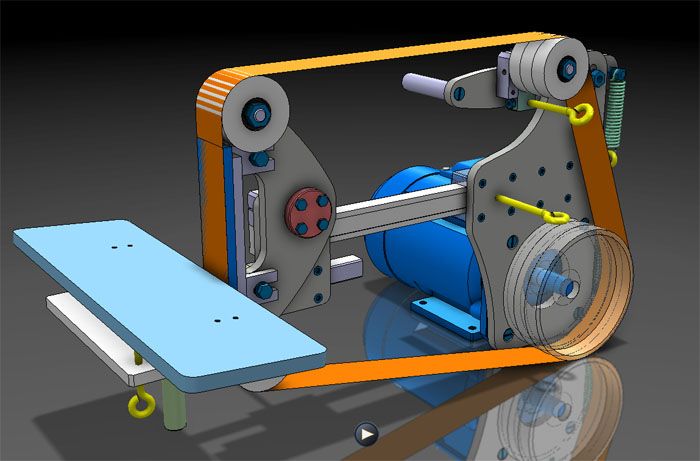

Schematic diagram of the grinder design and the principle of its operation

As we have already said, the design of the grinder resembles a simple device of a manual grinder. The movement of the sanding belt is carried out using rollers, and they are rotated by an electric motor. To make the belt stretch without sagging, there is a tensioning mechanism that moves one of the rollers. The difference from a manual unit is only in the presence of a device that fixes the workpiece. It is a table with a swivel mechanism and secure locks. The table can be rotated to handle parts from different sides.

To ensure safety measures while working with the rotating mechanism, the grinder is equipped with an acrylic screen.

The whole mechanism is connected to the universal machine using reliable fasteners. Factory made models are no doubt quite powerful and give the impression of being easy to operate. But home craftsmen complain about the unreliability of standard fasteners and the excessive length of the tape, which requires a high-power motor. So, not only because of the high cost, but also for purely practical reasons, many decide to make a belt grinder with their own hands. This work is not as difficult as it seems at first glance, and you can also use used spare parts from other mechanisms.

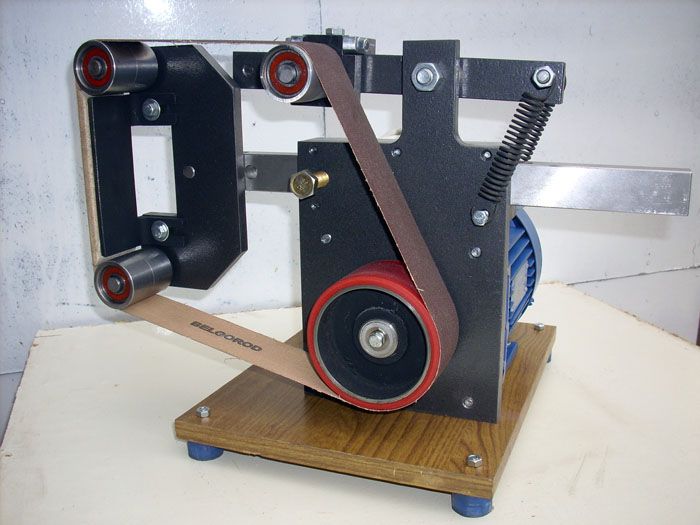

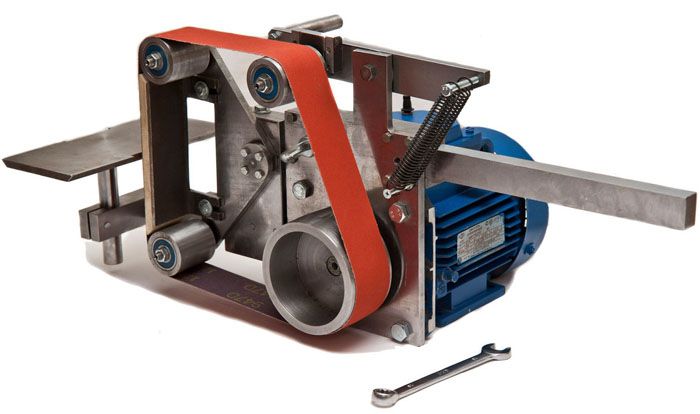

An example of a well thought-out mechanism is a grinder from Chapay

The brand "from Chapay" is a universal tool due to a competent and practically thought-out device and design

Chapaevsky machines are capable of processing wood, metal, plastic, stone. They are ordered by people who need constant use of this tool and its special tuning. Such grinders are an example of homemade devices with high performance. Here's a quick overview of one such model:

view grinder Chapay

Video and photo recommendations for making a do-it-yourself grinder at home

The device has gone through more than one upgrade, and now there are many "clones". For a person who is even in the slightest degree versed in mechanics, it is possible to repeat such an assembly with a share of patience and perseverance. Let's take a closer look at the details of the process.

What to make a drive for a grinder

The drive is the most important part of any machine. Select the right motor for the machine. The grinder requires an engine of one and a half to three thousand revolutions per minute with a capacity of 0.75 kW.

You can also use high-power motors, in kilowatts or more, but there is a danger that the emery tape will break

The performance of the device depends on the engine power. It is very convenient if there is a possibility of manual adjustment of the drive for solving various problems. When starting to make a simple grinder with your own hands, rummage through the trash in the garage or shed: there are probably suitable motors from units that have served their time.

Is it worth making a homemade grinder with a washing machine engine

Let's start with the controversial issue of making a do-it-yourself grinder based on an engine from a washing machine. It is controversial for one simple reason: during operation, a lot of dust and shavings, paint particles and other waste are generated on the device. They clog into the holes of the engine from the washing machine, and the structure quickly fails. But, nevertheless, for some craftsmen, such units work and successfully. An example of such a device in this video:

Step-by-step recommendations on how to make a grinder from a drill

A drill is a must-have tool in every home. Often something breaks in it, a case or an anchor, or maybe a new, more powerful and convenient model just comes out, so that the old one is gathering dust somewhere in a box in the garage.

How to do this in practice - let's analyze the process in detail in the photo and video instructions:

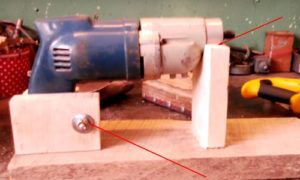

Do-it-yourself grinder from a grinder: drawings and ready-made nozzles

An angle grinder, or in a common way a grinder, is an almost ready-made basis for LSHM. On its basis, a machine is assembled according to the same algorithm as the above device from a drill. The scheme is as follows:

The result is a DIY mini grinder that will sharpen knives and scissors. There is an option not to start with homemade products, but to purchase a factory nozzle. It is attached to the grinder with a bracket. Finding such a device is not easy, but in this age of internet commerce, nothing is impossible. Such a gadget is convenient in that it is possible to use a working grinder without fundamentally violating the design of a working device.

Such a grinder is suitable for smoothing seams after welding. For other work, you will have to think about a stationary mount

How to make a grinder from a grinder with your own hands: video instructions

Another easy-to-use version of a home-made LSHM is from a conventional grinder. Almost all you need to do is fix the device to a workbench and set up an on and off system. More on this in the video.

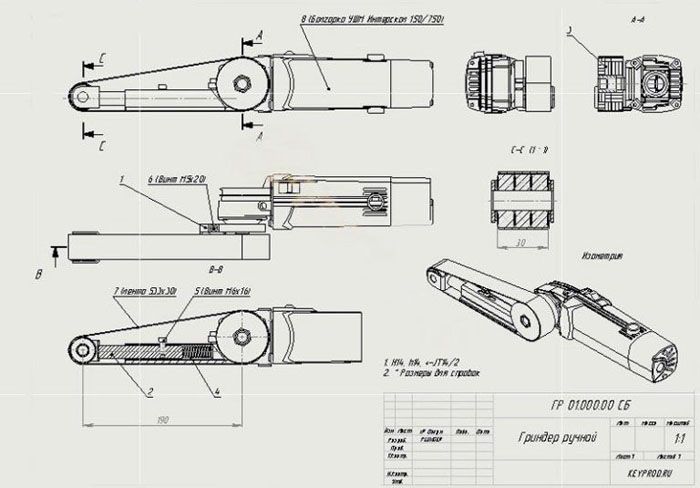

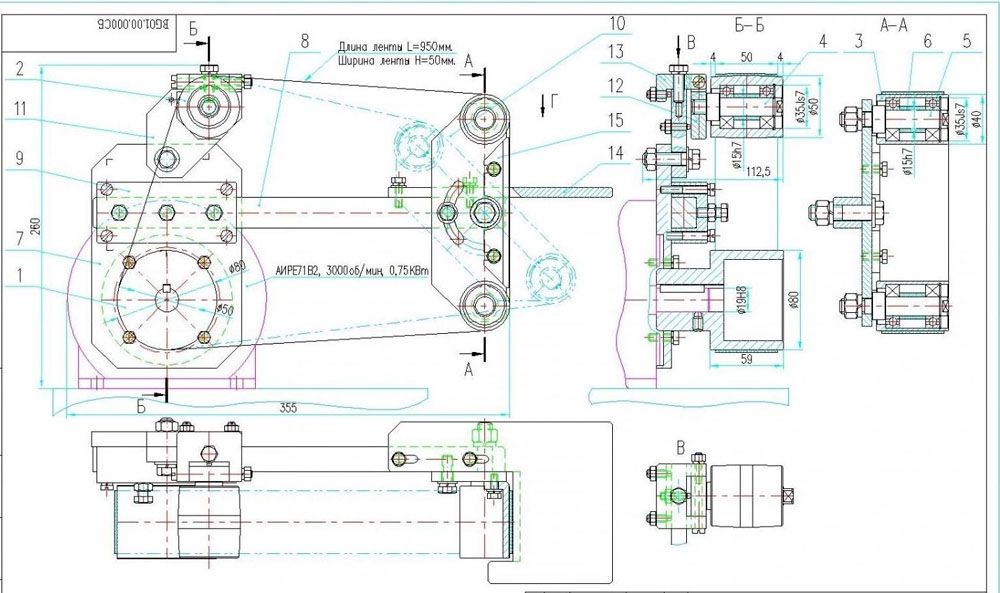

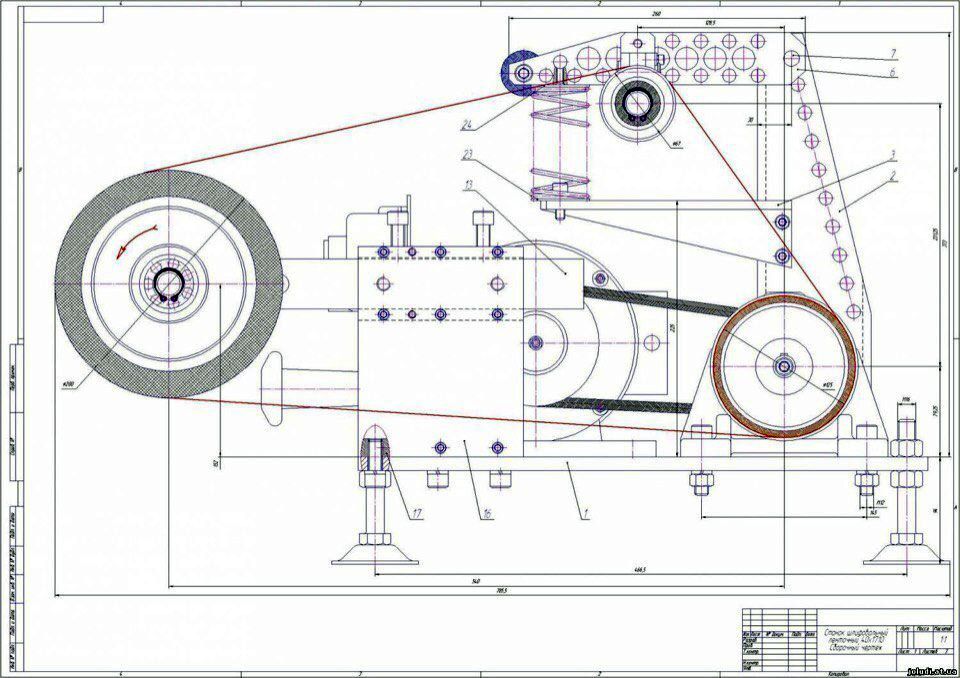

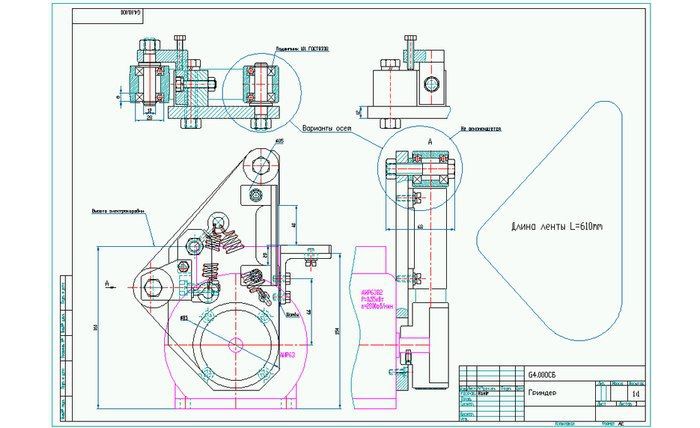

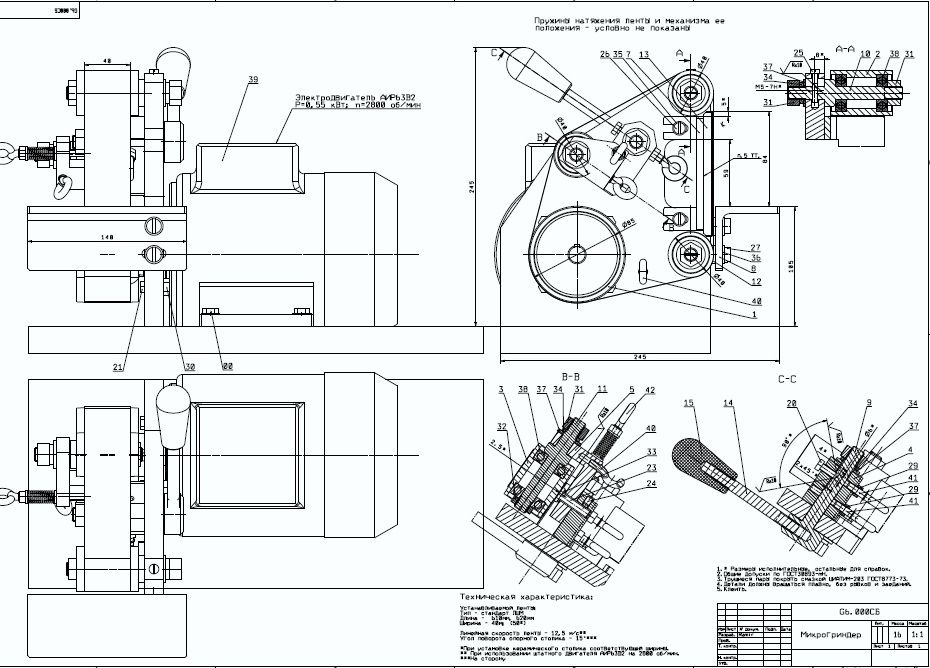

How to make a grinder with your own hands: drawings with dimensions from different authors

Each master brings something of his own to the design, so before you start making a sharpener from a grinder with your own hands, study the possible options. Here are some drawings for example:

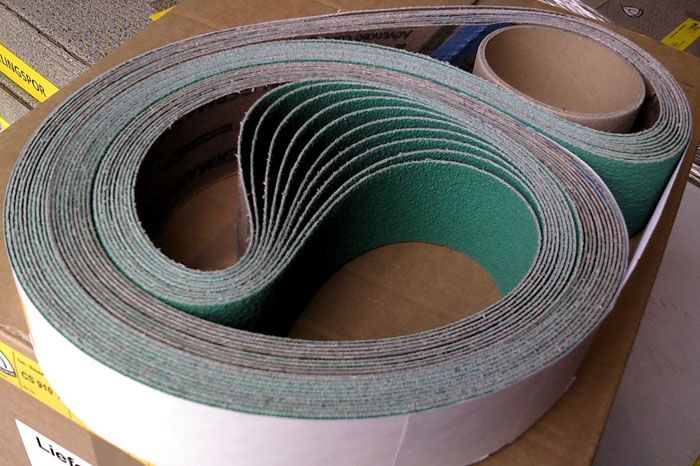

How to glue a tape for a grinder with your own hands and special requirements for it

When developing a homemade grinder with your own hands, it is better to provide for the use of standard size emery tape. The standard sizes are lengths in 1830, 1600, 1230, 915 and 610 mm and widths 100 and 50 mm. Then you don't have to puzzle over how to make a tape for a grinder with your own hands. Tape, homemade or factory made, must meet the following requirements:

- elastic fabric base;

- high ability to withstand angular velocities;

- abrasion resistance;

- the possibility of lengthening without breaking the integrity of 10-15%;

- minimum heating during long-term operation.

Advice! Do not use tapes longer than 1230 mm for your homemade tool, for them you will have to increase the dimensions of the structure, and this puts forward additional requirements for its placement.

When making the tape yourself, try not to make more than one seam. All seams are stretched during the sanding process, and the tape weakens

How to glue the tape at home:

- Cut a strip of the desired length and width from the emery sheet. Cut the edges of the tape diagonally.

- Connect the edges and pre-glue them on the abrasive side with masking tape.

- Fix the cut with a few drops of super glue.

- Apply glue to the cut point and a piece of silk tape, press the surfaces together.

- Wrap the bonding area with paper and press it overnight.

How and what to make do-it-yourself rollers for a grinder

The first rule is that the rollers should not be too heavy, otherwise the engine will not be able to immediately crank the heavy parts, and an inevitable jerk will follow, which can damage the belt. For this reason, it is not recommended to grind heavy steel rollers. In the best case, the steel roller should be hollow, and for this the turner will charge you almost twice as much. A good way out is to use duralumin: it is both light and hard enough to accomplish the task at hand. To prevent the tape from jumping off the roller, you need to make an end groove on it.

Important! The surface of the rollers must be rough within the range of 1.25-2.5 Ra. If the indicators are higher, the tape will wear out quickly. On smooth rollers, the sandpaper will turn.

Bearing assemblies must be kept closed to prevent debris from entering. Cotter pins are used to fasten the rollers on homemade LShM

How to make a pulley for a grinder with your own hands: video recommendations

A pulley for a banding machine can be made from a motorcycle wheel, regular plywood, wood, or other material at hand. Here's an easy-to-make example of a similar part:

Rotary table for grinder

Without a table, the grinder will not be able to process complex parts. The swivel mechanism with the possibility of fixing the part offers many advantages and allows precise processing. This device is made of duralumin. A bracket is attached to it so that the table can rotate horizontally. The thickness of the duralumin sheet is at least 1.5 cm. A thin sheet may not withstand the load.

Prices for household and professional grinders

If you do not have the ability and inspiration to work on a homemade product, you can buy a belt grinder online or at a tool store in your city. We have analyzed the most popular models of household and professional grinders and invite you to familiarize yourself with their prices:

If you purchased a professional or household grinder, share your impressions of working with the device in the comments. We will be grateful if you share your own experience in making a homemade device.