Manual wood router: where to use and how to choose

For wood processing, various machines and devices are used, with the help of which the necessary shape and configuration is given to the wooden blanks. For large volumes, industrial equipment (machine tools, sawmills, etc.) is used for these purposes, and for small volumes, for a home or workshop, work is performed using hand tools. One type of such equipment used for processing wood surfaces is a hand-held wood router, which will be discussed in this article in the online magazine homemaster.techinfolux.com/en/.

Hand-held wood milling cutters are an indispensable assistant for the home craftsman in the manufacture of furniture and the execution of curly carving

The content of the article

- 1 Scope of application

- 2 Varieties of hand-held milling machines

- 3 Main technical characteristics

- 4 Design features of the main units

- 5 Additional equipment for manual milling machines

- 6 The most common types of milling cutters for a manual router for wood

- 7 Review of popular models of hand-held milling machines

- 8 How to choose a manual wood router - recommendations of our editorial staff

- 9 How to make accessories for a wood router with your own hands - nuances

- 10 How much does a manual wood router cost - price overview

- 11 Video: basic rules for working with a wood router for beginners

Scope of application

Hand-held wood mills are a tool in which the cutting element is a milling cutter installed in a collet-type chuck, which, in turn, is placed in a mechanical gearbox driven by an electric motor.

Hand mills are used for:

- drilling holes of any diameter and shape, depending on the size of the cutters used;

- alignment of wooden surfaces, as well as the contours of parts and wooden blanks;

- cutting various grooves, splines and spikes;

- profiling of various types of edges;

- execution of decorative carving.

Carving is one of the main functions of hand held wood routers, and special types of hand tools (drills, planers, etc.) are usually used for drilling and leveling.

Varieties of hand-held milling machines

Hand mills are classified according to:

- The type of use - domestic and professional use.

- Purpose - universal and narrow-profile type of use.

- Constructions.

The way a tool is used is determined by its technical characteristics and functionality. Professional models can be narrow-profile, when using them it is possible to perform certain types of operations, and universal ones are devices for household and professional use, with which you can perform various types of woodworking operations.

By design and types of operations performed, manual milling machines are classified as follows:

- submersible (vertical or sucker rod) - universal devices, the most common type of instrument of this type;

- edging (edging) - narrow-profile models, used for grooving, grooving, chamfering in woodworking industries;

- lamellar - designed for grooving;

- filler (dowel) - used in furniture production for drilling paired holes for dowels.

Manual wood milling cutters which is better - it is decided by each user individually, in accordance with the purpose of the tool and the nature of its use.

Main technical characteristics

Any type of tool and equipment, technical devices and fixtures are characterized by certain technical characteristics that determine their capabilities.

For hand-held wood cutters, these characteristics are:

- electrical power, measured in watts;

- spindle speed, measured in revolutions per minute.

In addition, the following indicators are important technical parameters:

- availability of protection and automation systems;

- material used in the manufacture of the "sole" of the instrument;

- immersion depth (working stroke) of the cutter, measured in mm;

- dimensions of the attachment attachment (diameter), measured in mm or inches;

- the presence of auxiliary elements - stops and guides.

Electric power determines the type of use of the tool: professional models are equipped with more powerful electric motors and, conversely, household models are equipped with less powerful ones. It should also be borne in mind that the more powerful the engine, the heavier the tool.

For this indicator, milling cutters are classified as:

- lungs - power is up to 0.7 kW;

- average - the power of such devices is 0.7–1.5 kW;

- heavy - more than 1.5 kW.

For universal models, the spindle speed is 20,000–30,000 rpm, while for edge-type models this figure is 35,000 rpm.

Important! When working with hand routers, remember that the higher the spindle speed, the cleaner the surface to be machined and the easier it is to process hard wood.

The following can be installed as automation and protection systems on various models of hand-held milling cutters:

- systems for stabilizing the spindle rotation speed under load;

- smooth start of the electric motor;

- overload protection;

- protection against unintentional start.

The type of sole and the working stroke of the cutter, as well as the attachment point for the equipment and auxiliary elements, refer to the design features of a particular model.

Design features of the main units

The sole of the instrument is an important structural element that determines the purpose of the instrument and the nature of its use. Models of household and budget type have soles made of stamped metal, more expensive, professional ones are equipped with platforms made of aluminum alloys.

All additional devices and guides are attached to the sole, as well as vertical bars.The working surface of the platform, its lower part must have a special pad made of plastic or dense wood. The working stroke of the cutter is determined by the design of the rod mechanism, and it is this indicator that determines the functionality and productivity of this type of tool.

The head of the device moves along the guide rods, and the amount of immersion is adjusted using the handles. It can be fixed using a special lever located on one of the handles or with a special screw. Some models are made with a removable head part, which allows them to be used as a stationary mounted straight grinder or drill.

The range of cutters available for use with a specific router model depends on the attachment attachment point. the diameter of the cutter must match the diameter of the collet. If the diameter of the bore of the attachment unit is larger than the diameter of the cutter shank, then you can use special adapter sleeves, which can be purchased separately from the cutters if they are not included in the delivery set. The presence of stops and guides allows you to process workpieces with a high degree of accuracy and facilitates the implementation of complex and time-consuming operations.

Additional equipment for manual milling machines

The delivery set of hand-held milling cutters, as a rule, includes various guides and other auxiliary devices, but if they are not enough, then there is always the opportunity to purchase them separately or make them yourself.

Stops and a guide rail, a copying sleeve and an angle stop, as well as a compass ruler act as additional accessories for hand milling cutters. Parallel and horizontal stops allow you to process workpieces at an equal distance from the edge (edge) of these elements, and the guide rail serves for the rectilinear movement of the router. The copying sleeve is a round plate with a collar that fits into the opening of the support platform and provides a stop around the running cutter. An angular stop is used when making a copy from a finished product, and a compass ruler helps to process workpieces along a certain radius.

The most common types of milling cutters for a manual router for wood

The industry produces various types of cutters used with hand-held wood routers, they are classified as follows:

- by shank diameter - 6.8 and 12 mm;

- by design - prefabricated, with replaceable cutting edges and monolithic;

- by type of blades - high-speed (HM) and carbide (HSS);

- by appointment - groove and edge, combined and for the manufacture of lining, frame and figrean.

When choosing a wood cutter for a hand router, in order not to make a mistake when buying, you need to familiarize yourself with the catalog of similar products, which can always be found on the Internet or from companies engaged in sales woodworking equipment... Many manufacturers offer for sale sets of wood cutters for hand-held milling cutters, differing in configuration and purpose.

Among the users, the most popular sets of cutters for wood for a manual router of domestic and foreign manufacturers: tool company "Enkor" (Russia), "CMT Utensili SpA" (Italy) and Dimar Group L.t.d (Israel).

Related article:

Woodworking machines for the home workshop.Specialized equipment with an electric drive greatly simplifies the processing of wood blanks. But its acquisition is associated with significant investments. To successfully solve this problem, you should carefully study the materials in this article.

Review of popular models of hand-held milling machines

There are many models of hand-held milling machines of both domestic and foreign manufacturers on the domestic market for hand-held electric tools. The most popular in the different categories are the models shown in the following table in two categories - universal and hand-held edge milling machines for wood.

The most popular among domestic models is the Interskol FM-32 / 1900E manual milling cutter.

How to choose a manual wood router - recommendations of our editorial staff

Before you go to buy a complex and unfamiliar technical device, such as a manual milling machine, it is better to study the reviews of experienced users in advance, as well as search the Internet for recommendations from experts in the field of woodworking. Our reaction also has competent and qualified consultants who advise you to pay attention to the following points when choosing a model of a hand router:

- initially, you should decide what type of router is needed for use;

- for home use, "light" or "medium" models, which are distinguished by sufficient power and low weight, are quite enough;

- the presence of a plastic or other attachment to be put on the platform is mandatory, because it will prevent damage to the treated surface during operation;

- the rod mechanism must ensure smooth running without the application of significant efforts;

- the presence of adjustment of the rotational speed is an optional option, but it is much more convenient to work with it using mills of various types;

- smooth start-up and stabilization of work under load are useful if the tool is in sufficient demand;

- the manufacturer's brand guarantees its reliability, therefore, when choosing a tool, it is best to pay attention to the models of well-known companies.

How to make accessories for a wood router with your own hands - nuances

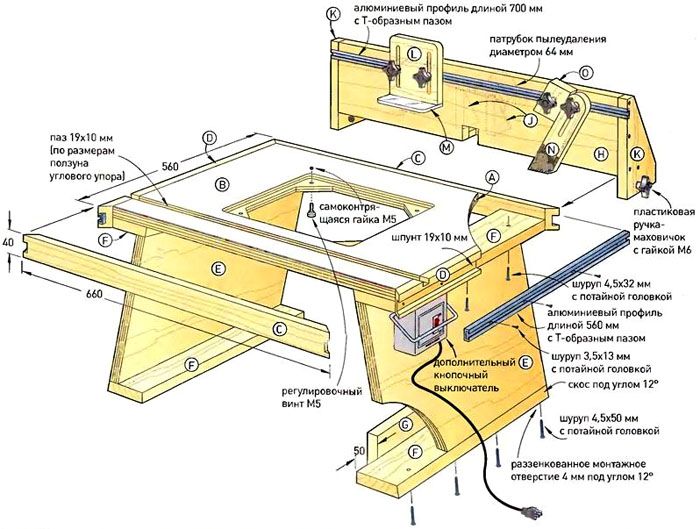

If you can buy additional equipment necessary for performing certain works, then it is better to make a milling table for a manual milling machine yourself. In this case, in order to avoid mistakes in manufacturing, it is necessary to pay attention to some nuances that should be taken into account when performing work:

- Before starting the work, it is necessary to draw up a drawing (sketch) of the object under construction.

- Regardless of the materials used, the assembled table must be strong and stable on the floor surface.

- Due to the fact that the router is attached from the bottom of the table top, it is necessary to provide for the possibility of access to the device for cleaning and performing other preventive work.

- The presence of a metal ruler located at the ends of the table will simplify the setting of dimensions during use.

- For convenience and the ability to quickly turn off the router in case of non-standard situations, you can install an additional control button directly on the table surface (emergency button of the "mushroom" type).

How much does a manual wood router cost - price overview

The price of a hand-held wood router depends on its technical characteristics, purpose and brand of the manufacturer, and you can buy such a tool in shops and retail chains specializing in the sale of woodworking equipment and hand-held electric tools.

When purchasing a tool in large retail chains, you can always count on a sales assistant to help you choose the right model.

Milling cutters are sold in building supplies stores and trade organizations specializing in cutting tools for various purposes. The following table shows the cost for the model of hand mills listed as the most popular in this article, as well as for a number of sets of milling cutters from the most popular manufacturers. The cost is indicated as of the II quarter of 2018.

A wide range of models and their availability allow you to choose a manual router in accordance with the purpose and technical characteristics in a given price range, and the opportunity to get advice is the key to a successful purchase.

The video below will tell you how to work with a manual router.