Saw, drank! Features of work on a stationary circulation saw, expert advice, rules for self-assembly

Among woodworking equipment, the most famous design among ordinary users is a circular saw, designed for sawing various types of sawn timber in accordance with specified dimensions. Stationary circular saw - the principle of operation and types, advantages and disadvantages of use, main technical characteristics, as well as how to choose and make with your own hands - this is the topic of this article in the online magazine homemaster.techinfolux.com/en/

The content of the article

- 1 Who needs a stationary circular electric saw

- 2 Advantages and disadvantages

- 3 Design features

- 4 Principle of operation

- 5 Types of stationary circular saws

- 6 General specifications

- 7 Accessories and useful add-ons

- 8 Popular models of stationary circular saws

- 9 How to choose a stationary circular saw for your home - our editorial advice

- 10 Making a stationary machine with your own hands from a hand-held circular saw

- 11 Features of manufacturing with a motor from a washing machine

- 12 Video: how you can make a circular with your own hands using an engine from a washing machine

Who needs a stationary circular electric saw

The main purpose of a stationary saw is to saw large pieces of lumber of various types.

Note! A distinctive feature of a stationary circular saw is a significant electrical power and a large cutting depth.

Due to their distinctive features, stationary circulars are used in various industries:

- construction of buildings and structures of various types;

- production of furniture and building structure elements (windows, doors, etc.);

- production of molded products;

- woodworking production of various directions.

A stationary circular saw is indispensable for all users working with wood and materials made with its use on a professional basis.

Advantages and disadvantages

A stationary circular saw belongs to a professional tool and, accordingly, the pros and cons of its use are associated precisely with a similar nature of operation. The advantages of this type of equipment are the following indicators:

- a wide range of processed materials and workpieces (lumber of various thicknesses, plywood, Fiberboard, Chipboard etc.);

- high accuracy of operations performed;

- the presence of a sufficient number of protective options to protect the user from injury during operation (protective cover, emergency stop button, connecting a vacuum cleaner, etc.);

- a variety of models allows you to choose the one you need, both by the type of execution (on the bed, tabletop) and by technical characteristics (electric power, voltage class, cutting depth, additional options).

The Belmash CBS-2400 model is placed on the floor, but due to the presence of wheels in its design, it can move on its surface

Of the disadvantages of a stationary circular saw, the following indicators should be noted:

- significant overall dimensions and weight, especially in relation to models "on the bed";

- significant noise level during use;

- high price.

Design features

The basis of the design of any electrical equipment is an electric motor, by means of which all other mechanisms of the device are set in motion. In the design of the circular saw, the electric motor is located on the machine frame. Its rotary motion is transmitted to the saw blade directly or through a transmission mechanism, depending on the design of the model. The features of such equipment include such elements as:

- the bed - the basis of the structure, is made of metal (steel, cast iron), and this is what determines the significant weight of the models equipped with it;

- table top - a working surface, has a groove for a saw and is also made of metal;

- the gearbox or pulley (depending on the model) is placed under the surface of the tabletop;

- on the working surface are elements to protect the worker from injury, as well as various devices that facilitate the performance of work and expand the functionality of the machine.

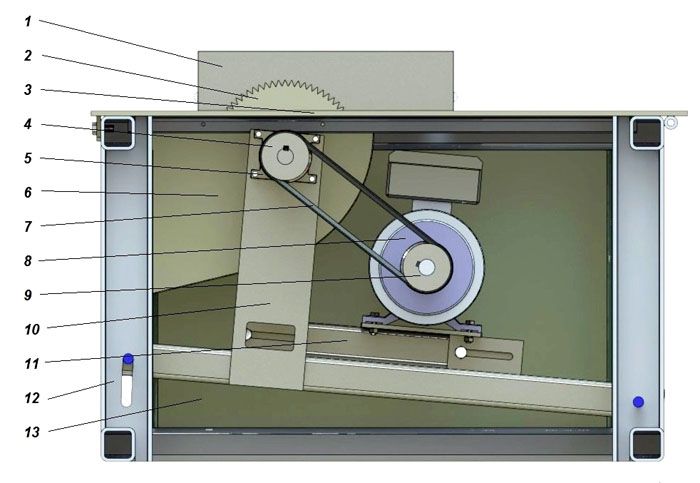

Diagram of the device of one of the variants of the layout of the stationary circular saw: 1 - stop plate, by means of which the width of the cut-off part is adjusted; 2 - saw blade; 3 - work surface (table top); 4 - saw blade drive shaft pulley; 5 - saw blade drive shaft with bearing assembly; 6 - a casing that ensures the removal of sawdust generated during the use of the machine; 7 - belt used to transmit the rotational motion of the motor shaft to the saw blade drive shaft; 8 - electric motor; 9 - a pulley mounted on the shaft of an electric motor; 10 - movable bed; 11 - unit for attaching the electric motor to the machine body; 12 - machine base - stationary bed; 13 - a structural element serving to close the internal space of the machine (protective panel).

Principle of operation

The operation of a circular saw is based on the use of electrical energy, through which, when voltage is applied to the terminals of an electric motor, it begins to rotate. The rotary motion of the motor shaft is transmitted to the circular saw blade, which, when it comes into contact with the workpiece, cuts it. Different models may differ in design, which determines the method of transmitting rotary motion, and the type of execution, which determines the way of placing the circular.

Types of stationary circular saws

By its design, such equipment can be quite different: with a cast base and prefabricated type, tabletop and combined execution.

Cast Base Models

Circular saws of this design are used, as a rule, in industrial production and are the most stable, which is explained by the method of attachment to the floor surface (concrete base or special foundation). A distinctive feature of models of this type is significant weight, which allows processing massive workpieces, and low vibration during use.

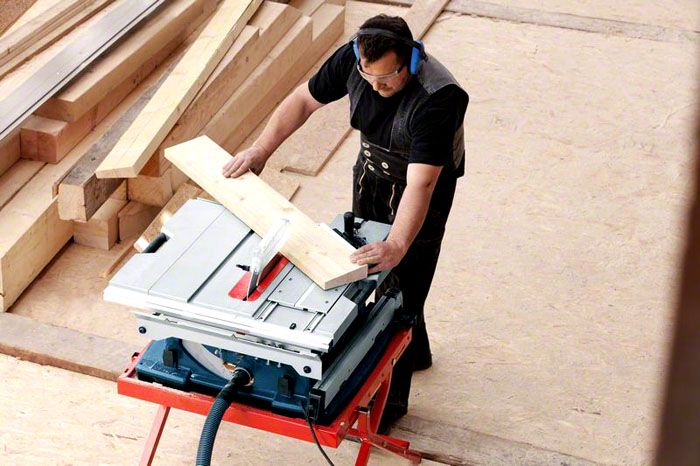

Table circular saw

Tabletop models are distinguished by their smaller overall dimensions and weight, which allows them to be placed on the surface of the table, either specially made for this, or included with the machine. This type of equipment can be used both in small production conditions and for individual use. As a rule, desktop models are connected to a household electrical network with a voltage of 220 volts. They are equipped with the necessary devices (stops, rulers, fastening elements) that expand their functionality.

Combined models

The machines, when using which you can perform several types of operations related to the processing of wood and other panel materials, are combined. Stationary circular saws, in addition to the saw blade, through which the workpieces are processed and which is the main element of such equipment, can be equipped with a milling cutter and a sharpening disc, a chuck for drilling workpieces, as well as other types of equipment that expand their functionality.

Note! The presence of several types of equipment in a single design, as a rule, leads to a decrease in the functionality of each of them, in comparison with the option of separate use.

General specifications

According to the technical characteristics, the equipment is evaluated for its use both in terms of workpieces to be processed, and the possibility of installation in a particular location. For a circular saw, these characteristics are:

- electrical power - is set by the power of the electric motor, all other technical characteristics depend on it, as well as the method of connection to the electrical network (voltage class and cross-section of supply wires / cables);

- cutting depth - determines the size of workpieces that can be cut on a particular machine, depends on the power of the electric motor and the diameter of the saw blade that can be used on a particular model;

- saw blade rotation speed - determines the cut quality of the workpiece being cut;

- additional options: smooth start-up of an electric motor and a sawdust removal system, protection and automation systems (from overheating, jamming, etc.), as well as measuring rulers and angles of various types.

Important! When choosing a model, you need to know that the more powerful the electric motor, the longer you can use the machine without stopping. Also, durable wood or other material is available for processing on such equipment.

Accessories and useful add-ons

The main piece of equipment for a circular saw is a saw blade, which can vary in outer and inner diameters, thickness, as well as angle and tooth shape. The outer diameter determines the depth of cut of the workpiece being cut, and the inner diameter determines the fit size, which must correspond to the diameter of the saw blade drive shaft. According to the angle of inclination of the teeth, saw blades are classified: with a neutral, positive and negative angle of inclination.

Note! The nature of the effect of the saw blade on the surface of the material being processed depends on the angle of inclination of the teeth.

As useful additions, special handles can be placed on various models to facilitate the use of the equipment, as well as clamps and other fastening elements that expand the functionality of the machine.

Popular models of stationary circular saws

On the domestic market of woodworking equipment, there are models of stationary circular saws produced in different countries of the world. Among them, according to the reviews of real users, the most popular are brands such as: Bosch and Metabo (Germany), Makita and Hitachi (Japan), Interskol (Russia) and JET (Switzerland). Consider the characteristics of the most popular models.

| Picture | Model | Specifications |

|---|---|---|

| "Metabo TS 254" | Power - 2 kW; Saw blade diameter - 254 mm; Weight - 33.4 kg; Additional options - soft start. |

Feedback on the model "Metabo TS 254":

| Picture | Model | Specifications |

|---|---|---|

| "Bosch PTS 10" | Power - 1.4 kW; Saw blade diameter - 254 mm; Weight - 26 kg; Additional options - soft start. |

Feedback on the "Bosch PTS 10" model:

| Picture | Model | Specifications |

|---|---|---|

| "Makita 2704" | Power - 1.65 kW; Saw blade diameter - 255 mm; Weight - 30 kg; Additional options - soft start. |

Feedback on the Makita 2704 model:

| Picture | Model | Specifications |

|---|---|---|

| Hitachi C10RD | Power - 1.6 kW; Saw blade diameter - 250 mm; Weight - 24.6 kg. |

Feedback on the "Hitachi C10RD" model:

| Picture | Model | Specifications |

|---|---|---|

| "Interskol DPN-250 / 1500P" | Power - 1.5 kW; Saw blade diameter - 254 mm; Weight - 37 kg. |

| Picture | Model | Specifications |

|---|---|---|

| "JET JBTS-10" | Power - 1.7 kW; Saw blade diameter - 254 mm; Weight - 35 kg. |

Feedback on the model "JET JBTS-10":

How to choose a stationary circular saw for your home - our editorial advice

Choosing a circular saw for your home is not so easy as it might seem at first glance, and there are several reasons for this:

- a large number of models that are similar in technical characteristics and in a wide range of price indicators;

- novice users have no experience with similar equipment.

In this case, sales consultants at the point of sale and specialists with experience in woodworking machines come to the rescue.

The convenience of working on it and its mobility depends on the size of the circular saw.

Our editorial office has its own consultants in this area of technology, and here is what you should pay attention to first of all:

- Technical characteristics determine the cost of the model, therefore, you should initially determine the purpose of the equipment and its potential load.

- When choosing a model with a powerful electric motor, make sure that the machine can be connected to an existing electrical network.

- When choosing a low-power model, one should initially understand that it will be impossible to perform large-scale work on such equipment.

- The larger the working surface, the more convenient the machine is in work, and, accordingly, with greater accuracy you can process workpieces.

- Mobile models are more suitable for one-time work, and bed-mounted models are more suitable for industrial use.

- The presence of additional options and a combination with other types of equipment increases the cost of the model, therefore, when choosing it, you should evaluate the feasibility of such additions.

- The reliability of the equipment depends on the manufacturer's brand, and the efficiency depends on the electrical power of the engine used.

Making a stationary machine with your own hands from a hand-held circular saw

There are situations when a hand-held circular saw is available, and a stationary structure is required to perform work, which is caused by the need for processing long workpieces or a large volume of operations of the same type. In this case, you can independently make a table on which to place an existing hand-held electric tool, and then use it as a permanently installed equipment. All work can be divided into several stages: preparation, manufacturing and installation, performance check.

Preparatory stage

At this stage of the production of work, a material is prepared from which the working surface (table) of the machine being manufactured will be made, as well as its basis, a sketch is developed. A hand-held circular saw is being prepared, as well as other elements: wires and cables, a button or an automatic machine for turning the circular saw into operation.

Manufacturing and installation

After the tool and materials are prepared, and a drawing (sketch) of the assembled structure has been drawn up, you can start making it.

Note! The circular table can be made of a metal profile or wooden bars, and the working surface can be made of lumber or metal that does not corrode.

The manufacturing sequence from wood blanks and plywood is shown in the following table.

This structure can be installed separately or placed on any horizontal surface. Its geometric dimensions depend on the dimensions of the hand tool, as well as the needs of the user.

Functional check

When the structure is assembled, it must be checked in operation, for which it is connected to an electrical network corresponding to the voltage class of the circular saw used. When the performance has been verified, the manufactured product can be supplemented with the necessary accessories (stops, clamps, etc.) and devices that facilitate use during operation.

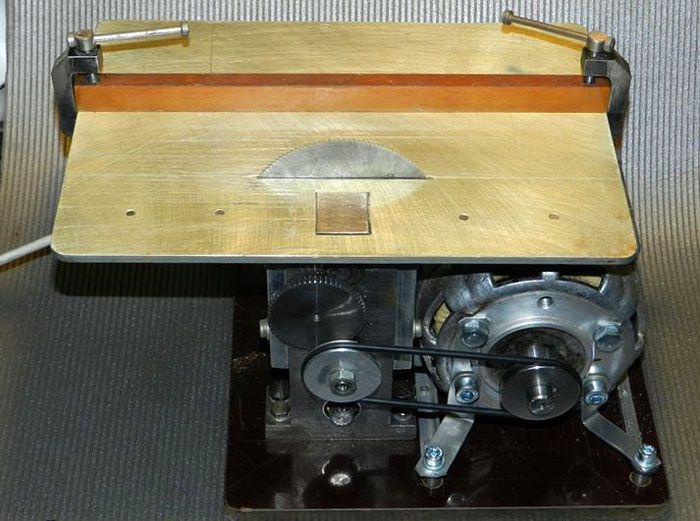

Features of manufacturing with a motor from a washing machine

Quite often it happens that an old washing machine is stored in a garage or other utility room, but it can be "given" a new life by using an electric motor to make various equipment needed in a household. One of these options is the manufacture of a circular saw.

When using an electric motor from a washing machine to make a stationary circular saw, a number of features must be taken into account:

- motors used in washing machines generally have little electrical power. Therefore, you should not expect that with their use it will be possible to process large workpieces;

- to ensure the required number of revolutions of the saw blade, it is necessary to use a transmission mechanism that provides an increase in this indicator in relation to the factory characteristics of the electric motor (gearbox, the use of pulleys of different diameters, etc.);

- the saw blade must be placed on a special shaft, the rotation speed of which can be adjusted by means of the transmission mechanism.

Note! The design of a circular saw table using a motor from a washing machine can be completely different and depends on the user's needs and the materials available.