Bimetallic heating radiators: which is better to choose?

When choosing radiators for heating systems, you should first pay attention to their technical parameters, efficiency and cost. Among all the types of heating batteries existing today, bimetallic ones are considered optimal in terms of cost and quality. Their popularity is due to their unpretentious operation and increased reliability. They are presented in various designs and may differ significantly in technical characteristics. Bimetallic heating radiators, which are better and what should you pay attention to when choosing?

The content of the article

- 1 Design and types of devices

- 2 Criteria for assessing the quality of the heating battery

- 3 How to calculate the number of battery sections correctly?

- 4 Rating of bimetallic heating radiators: prices and popular manufacturers

- 5 Bimetallic heating radiators: which are better?

- 6 Conclusion

- 7 Video: how to choose heating devices?

Design and types of devices

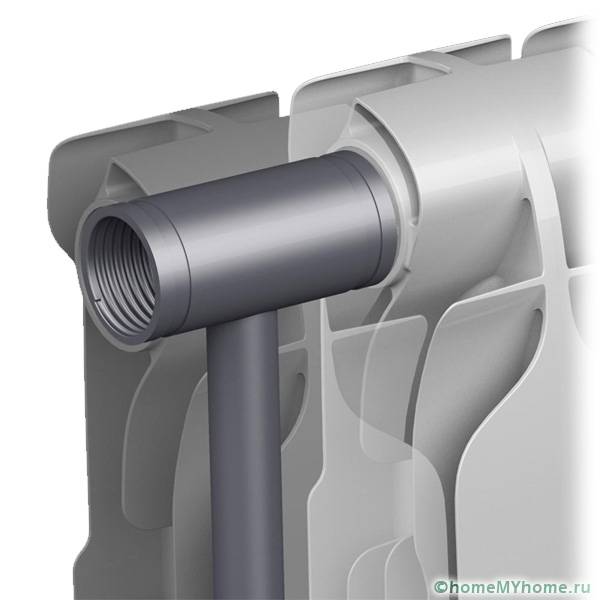

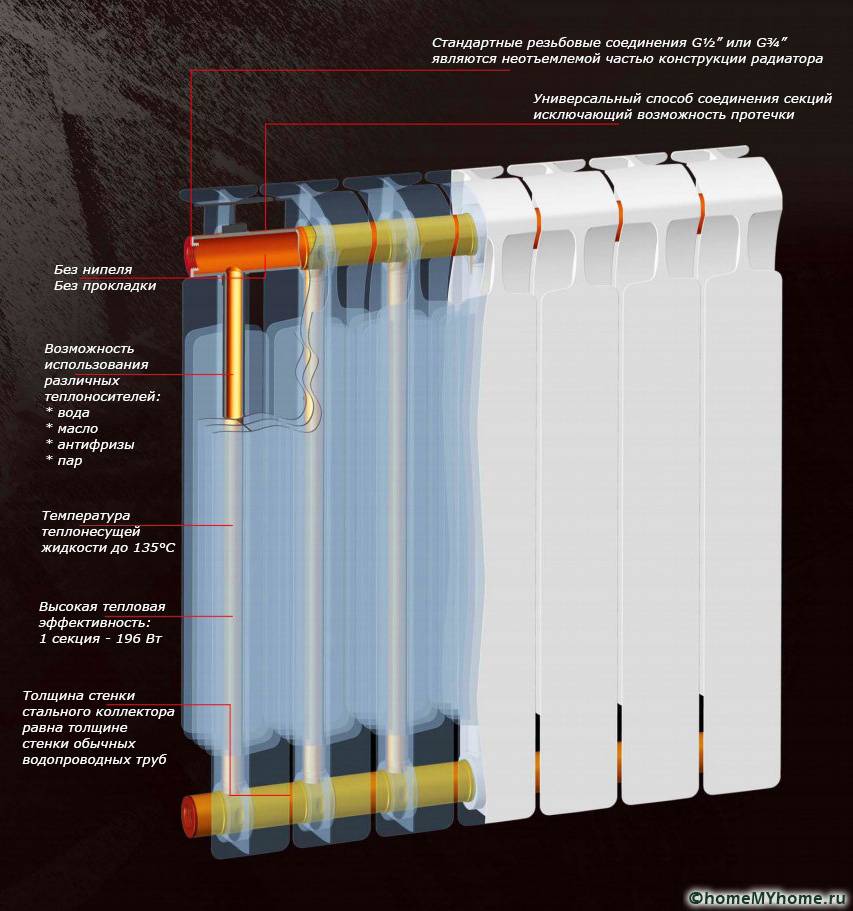

The design of bimetallic devices was selected in such a way that they provide both high-quality heat dissipation and are resistant to the negative effects of the coolant. For the circulation of the liquid medium, channels are created, made of stainless steel or copper, with a high surface quality. Due to this, corrosion foci do not form on their surface, and various impurities in the form of scale or deposits do not accumulate. The arrangement of pipes for circulation can be vertical or horizontal, which makes it possible to organize heating systems with forced or gravity circulation.

The outer part of the batteries is made of aluminum or copper. Since these metals have high thermal conductivity, the heat from the coolant will quickly heat up the massive structure and it will effectively transfer heat to the room. It is a casing with a large area for heat dissipation. The diffuser is usually made in the form of an array of thin plates parallel to each other. The more ribs, the more efficiently the battery dissipates heat. The inner channels are interconnected by a cast, stamped or welded method.

Types of radiators by design type

Bimetallic heating radiators, which one is better to choose? The answer to this question lies in the features of their designs, advantages and disadvantages.

A modern heating battery can be divided into sections or represent a monolithic structure. Sectional ones allow you to configure the heating system with high accuracy without unnecessary overpayments. The sectional connection can be made on threaded connections. As branch pipes and nipples, materials with low thermal conductivitythat prevent excessive heating and leakage of the connection. As seals, special rubber-based gaskets are used that can withstand heat up to + 200 ° C.

Monolithic radiators have high reliability, ease of installation and long service life. The absence of threaded connections also allows it to withstand significant increases in coolant pressure without deforming the body. Therefore, it is recommended to use them in centralized heating systems of multi-storey buildings, where there is no guarantee that a stable pressure will be provided. The disadvantages of such designs are as follows:

- If one of the sections is damaged, you will have to perform a complete replacement of the radiator.

- The number of sections is strictly fixed, which will not allow you to save money if there are non-standard heating requirements.

- When the internal channels are clogged, cleaning is very difficult, and with heavy scale it becomes impossible.

Semi-metallic batteries

If you choose bimetallic heating radiators, which are better and which are not, then you should also pay attention to semi-metal structures. Their main difference is that instead of solid internal channels made of stainless steel, combinations of stainless steel and aluminum are used. Placement of aluminum sections exclusively in horizontal segments of the structure. This is due to the fact that the heat during heating will spread directly to the dissipating plates and the efficiency will be at the level of classical bimetallic radiators. This reduces their overall cost.

In application, semi-metallic batteries are quite capricious, since, in fact, they implement a joint of two metals, which has different coefficients of thermal expansion and strength characteristics. That is, with a sharp supply of the nominal working pressure of the coolant, microcracks or even damage to the inner part may occur. Therefore, they are not recommended for use in uncontrolled heating systemswhere pressure can rise sharply.

If we compare bimetallic heating radiators with semi-bimetallic ones, which ones are better than them, and which ones are worse, then many manufacturing companies try to focus on expert reviews and operate them for marketing purposes. However, the opinions of a common man in the street, who bought and managed to test a heating battery in real conditions, do not always coincide with an expert who only conducted tests. Therefore, it is worth focusing on both opinions when choosing a suitable heating device, and drawing conclusions yourself.

Helpful information! Semi-metallic batteries are very sensitive to aggressive coolant compositions by the occurrence of corrosion processes at the joints of two metals and the appearance of leaks. Therefore, when buying such radiators, it is recommended to pay attention to their assembly, as well as the availability of appropriate quality certificates.

Which heating radiator is better: aluminum or bimetallic?

Based on the above, a reasonable question arises as to which heating radiators are better than aluminum or bimetallic? On the one hand, aluminum ones have excellent thermal properties, and on the other hand, their cost is quite high.Therefore, as an alternative, with a slightly worse efficiency and heating rate of the sections, but with a higher strength, it is advantageous to pay attention to bimetallic structures. They are able to operate in heating systems that are rather heterogeneous in terms of operating parameters, are more resistant to aggressive properties of heat carriers and are unpretentious in operation. To clean them, you can use special products containing aggressive components.

The presence of dirt in the battery is the result of the use of low-quality materials in the manufacture of the structure

Attention! It is highly discouraged to use aggressive detergents for semi-metallic batteries.

Criteria for assessing the quality of the heating battery

To understand about bimetallic heating radiators, which are better for an apartment, and which are for a production facility, you need to understand their technical characteristics and identify all design flaws. First of all, it is worth paying attention to the working pressure, which is usually up to 25 atm for sectional structures or up to 100 atm for monolithic ones. Stronger monolithic batteries will allow for maximum leak-free service life, even in conditions of sudden pressure surges in the heating system. Naturally, the cost of better quality radiators will increase by about 20-30%, depending on the manufacturer and model.

Another important selection criterion is to ensure high efficiency. Structurally, this means that the larger the dissipation area of each section, the higher the energy efficiency. The best option is considered when the width of the end part of the radiator is at least 70 mm, and the thickness of the protruding plates is 1-2 mm (for expensive models this parameter is 1-1.5 mm). However, at the same time, thin at the ends and wide in the main plane, the plates will have insufficient strength, therefore it is recommended to refuse to purchase them if the thickness of the plates is less than 1 mm.

The indicators of the reliability of batteries are the following parameters:

- The wall thickness should be between 3-3.5 mm.

- The material of the gaskets is rubber or rubber with high degrees of elasticity and softness.

- Ribs and nozzles should not deform or break with minimal mechanical stress.

- Long term manufacturer's warranty, usually over 25 years.

How to calculate the number of battery sections correctly?

If suitable bimetallic heating radiators are selected, which are better defined unambiguously, then it is worth moving on to carrying out the calculations. To determine the number of batteries and sections in each of them, it is necessary to carry out complex heat engineering calculations, which will take into account the degree of insulation, the area of the windows, the presence of external walls in the room, as well as other sources of cold. However, for heating apartments or small rooms, you can use a simplified calculation scheme, which will allow you to provide a heating margin within reasonable limits and not create unnecessary overpayments.

A simplified calculation scheme is based on the principle of the need to consume 100 W of heat energy for heating 1 m2 area of a room with a height of 2.5 m and, accordingly, obtaining a comfortable temperature. Therefore, you must first measure the length and width of the room in meters. To do this, you can use a laser meter or tape measure. The resulting values must be multiplied to get room area.

The number of sections is determined by the following formula:

N = S × 100 / Pwhere

S - the area of the room;

P - thermal power of one section, which is provided by the manufacturer of the device.

When a rational value is obtained, it must be rounded up.It is clear that it is not always possible to carry out accurate measurements using such a formula, therefore it is necessary to multiply the obtained value by correction factors, which can take into account various factors that require increased heating. You can take specific coefficients in SNiP 41-01-2003. Or you can use the calculator we have developed below:

Attention! If it is required to calculate the number of non-separable batteries, then the thermal power of the entire heating battery must be substituted into the formula. The resulting value will also have to be rounded up.

Rating of bimetallic heating radiators: prices and popular manufacturers

There are many foreign and domestic manufacturers of bimetallic batteries on the heating system market. Therefore, it is quite difficult for beginners to make an unambiguous choice in favor of one model or another. To help you figure out the choice, you need to familiarize yourself with the brief table 1 below, which is based on the rating of bimetallic heating radiators with approximate prices in Russia.

Table 1. Average cost of bimetallic sectional batteries by manufacturer.

| Manufacturer | Dimensions | Thermal power, W | Average cost per section, rubles |

|---|---|---|---|

| Rifar (Russia) | 575x95x80 | 185 | 900 |

| 570x100x80 | 204 | 780 | |

| 415x90x80 | 104 | 660 | |

| 261x100x80 | 104 | 650 | |

| LLC "LITIZ" (Ukraine) | 570x82x80 | 166 | 585 |

| 575x85x80 | 169 | 665 | |

| Grandini (Italy) | 432x80x82 | 130 | 565 |

| 580x80x80 | 167 | 698 | |

| Global Radiatori (Italy) | 415x81x80 | 120 | 1015 |

| 565x81x80 | 171 | 1030 | |

| Royal Thermo (Italy) | 564x80x80 | 168 | 700 |

| 560x80x80 | 167 | 690 | |

| Tenrad (Germany) | 563x80x96 | 190 | 665 |

| 563x75x75 | 142 | 599 | |

| 413x80x96 | 139 | 579 | |

| Gordi (China) | 425x80x85 | 140 | 270 |

| 280x80x96 | 112 | 249 | |

| 580x80x80 | 183 | 283 |

Bimetallic heating radiators: which are better?

List of major manufacturers of bimetallic batteries:

- Rifar. A domestic manufacturer that appeared on the market relatively recently, but has already become a leader in the field of creating heating systems. All production is based on the Italian technologies of the Global company with the use of automated production lines. That is why the products are of the highest quality and lowest prices in comparison with foreign counterparts.

- LLC "LITIZ". Founded over 20 years ago in Ukraine. Specializes in the creation of high-quality die-cast aluminum radiators. It has its own production workshops and foreign equipment, which allows it to create high-quality products. The main line of bimetallic batteries is "Altermo", which is distinguished by the use of modern original developments in metal welding and powder painting.

- Grandini. The company specializes in the manufacture of heating systems for residential and industrial premises. It uses a multi-stage control system for all stages of production, so all products are of exceptionally high quality.

- Global Radiatori. It has been manufacturing products for heating systems since 1971 and has already become known all over the world for their impeccable quality and long warranty. Bimetallic batteries are the most adapted for domestic operating conditions, since they allow them to withstand significant pressure drops and surges in the system, are resistant to low-quality coolants, etc.

- Royal Thermo. It has been on the heating systems market for over 50 years and has become a global brand for the production of bimetallic radiators. It differs from other manufacturers by the presence of series of products with original shapes of diffusers and the use of exclusively high-quality components, as well as its own technologies.

- Tenrad. The company was founded by practical scientists who managed to bring innovative ideas into reality and create a successful production of bimetallic radiators. She is known for creating a heating system for the Olympic Games in 2005. The production base is based on modern equipment from leading countries such as Italy, Germany and France.

- Gordi. Despite the fact that the manufacturer is from China, he truly deserves trust among buyers, as his products are of exceptionally high quality. Batteries are cheap, but at the same time they use modern technologies that are in no way inferior to domestic ones. Therefore, they are direct competitors with well-known brands.

Based on Table 1 and information on manufacturers, you can choose bimetallic heating radiators that are suitable for technical parameters, determine which of them is better and which should be discarded.

Conclusion

- The basic designs of bimetallic batteries are described.

- A simple scheme for calculating the required number of sections is presented.

- The advantages of some branded manufacturers are described, as well as prices for the main product lines.

Video: how to choose heating devices?