Corrugation for wires and cables: types and bases of installation

To protect the wiring from external mechanical damage, a strong and reliable casing is required. A corrugation for wires and cables is the optimal tool for this purpose. It will not only protect the wires from damage, but also act as additional insulation, eliminating the risk of electric shock if the integrity of the cable is violated.What is a protective corrugation, how to mount it correctly? Let's talk about this in more detail.

The content of the article

What is corrugation for, the advantages of using

When laying engineering networks, it is necessary to ensure their protection from external influences and protect a person from accidental electric shock. Previously, the wiring was recessed under plaster, which acted as a kind of protection against accidental mechanical damage to the wire. In the event of any problems, the repair of the wiring turned into a major destruction of the wall. Two decades ago, a universal and very convenient means for wiring appeared - a corrugated pipe.

This casing is also recessed into specially made channels in the wall and sealed with plaster, but the cable inside the corrugation is free and can be removed from it if necessary. This procedure does not compromise the integrity of the wall.

Benefits of using corrugation:

- Fire safety. The heat-resistant corrugation for electrical wiring does not burn, and when a combustion source occurs, it shrinks around the damaged cable and does not allow air to penetrate to the fire.

- Corrugated protection insulates the electrical cable from water, which is especially important for rooms with high humidity levels.

- The corrugated hose is easy to install and does not require special skills.

- The price of such protection is low and available to any consumer.

Corrugation for wires: design

The corrugated wiring protection is a flame retardant PVC hose with specially shaped walls. It consists of rings of material, different in thickness and diameter. This design allows the hose to hold its shape, be resistant to external influences, and at the same time remain flexible. The mobility of the corrugation connections makes it possible to make wiring at right angles.

In addition to PVC, high or low pressure polyethylene can be used as the main material, it is also resistant to moisture and mechanical damage.

Helpful information! The color of the corrugation may indicate its material and special properties. Orange or red hoses are more fireproof than blue and black, and gray indicates PVC is used in the product.

Product types

Corrugation for wiring has several varieties. Each type differs in the material used and the purpose.

Thin wall hose

Differs in lightness and flexibility. Used for wiring, which is located in places inaccessible to mechanical impact. Most often, such electrical protection is used for wiring in frame houses, when installing suspended ceilings.

Heavy duty hose

Can withstand pressure and friction, resistant to extremes of external temperatures and humidity. It is successfully used for electrical wiring in concrete and underground. Can be used in humid rooms: sauna, greenhouse, bathroom.

Corrugated metal pipe for electrical wiring

The metal corrugated pipe for the cable is the maximum protection for wiring and is used at especially important facilities: hospitals, child care facilities and other places with increased electrical safety requirements. It is usually laid in the concrete and then the cable is pulled.

Helpful information! Corrugated pipes have standard sizes: from one and a half to five centimeters of the outer diameter and from one to four - the inner diameter.

How to choose corrugation

Each type of wiring corresponds to a certain type of protection:

- for telephone, computer and other thin wires, a pipe diameter of sixteen millimeters is sufficient;

- connection of powerful devices and coaxial cable - two centimeter diameter;

- interfloor wiring requires a four-centimeter corrugation;

- any hose described above can be laid in concrete and brick;

- in houses built using the frame method, only non-combustible PVC and HDPE are used.

Plastic and metal corrugation for cable: price

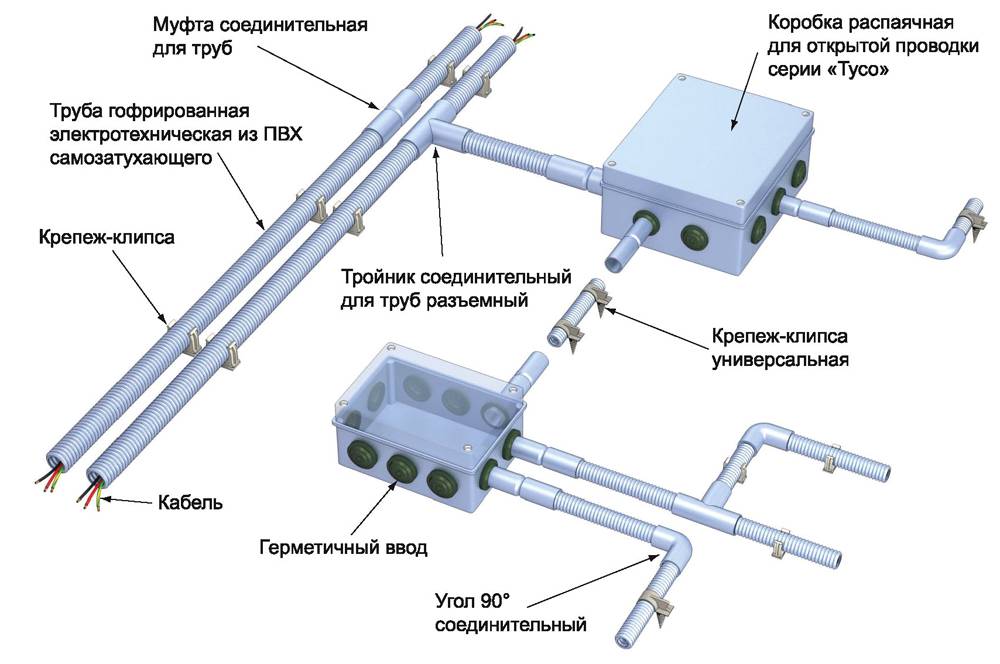

Mounting

Mounting protection for the cable is not particularly difficult, but it has some features that you need to know.

Procedure:

- It is necessary to accurately measure the length of the wiring and cut the appropriate piece of hose. For metal corrugation, metal scissors are used, PVC is cut with an ordinary knife. If there is a broach in the corrugation, it must be held and cut with nippers.

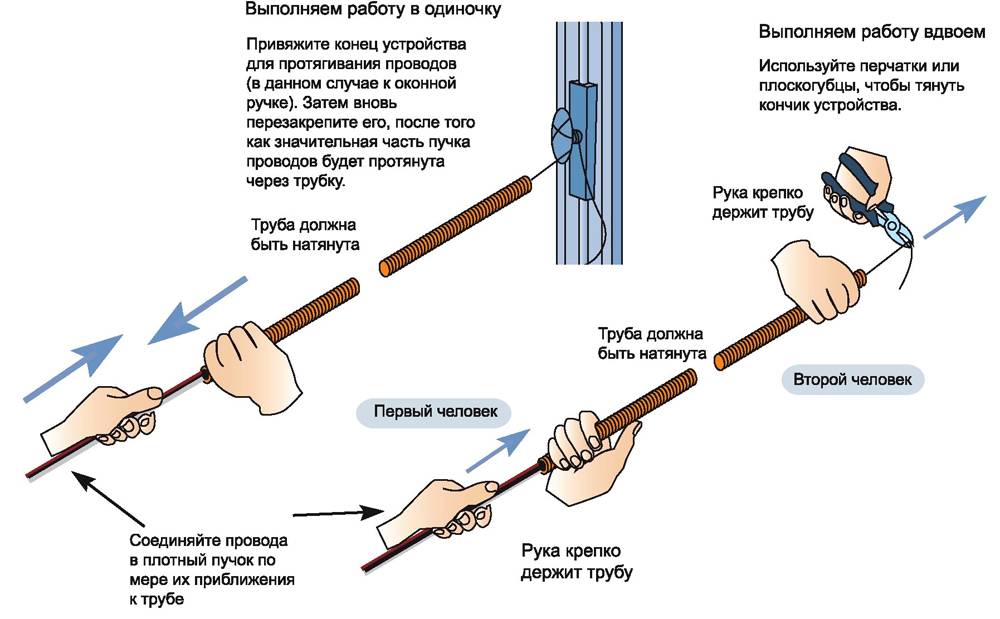

- At the tip of the broach, you need to fix the harness to fix the wires. Pull the cable.

- Secure the hose with wiring using clips or tape for installation.

Note! The corrugation for the wires should not sag. It should fit into sockets and switches so that its edge fits into the case.

If there are several wires in the corrugation, they are pre-fastened with electrical tape, wrapping around the entire length. The smooth surface of the tape will help prevent wires from getting stuck during pulling. If there is only one electric cable, there is no need to wrap it.

You can fasten the broach and the harness in different ways:

- wrap the wire around and squeeze tight;

- wind the harness with electrical tape;

- make a small hole in the edge of the wire and hook the broach hook into it.

It is better to put on a corrugated hose with an assistant. One person pushes the hose while the other holds the broach. If the broach has come off, the sleeve is cut off at this point and the process continues further. The cuts can then be sealed with electrical tape.

Video: how to thread a cable into a corrugation

A few tips

- When wiring, sharp corner joints should be avoided whenever possible.

- If the length of the wiring is too long, the corrugation joints must be reinforced with transit boxes.

- Metal sleeves for wiring are fixed on the metal frame before pouring with concrete. In this case, the wires are pulled after the concrete has formed.

Helpful information! It is possible to lay electrical protection in concrete walls in grooves. On wooden structures, it is fixed with clamps or metal brackets.

In the distribution box, the corrugation must be firmly fixed in the holes. Over time, the material may "sit down" a little and shrink, therefore fastening at the joints is very important.

Note! Metal protection for wiring must be grounded.

Outcome

Corrugation for wires is a reliable protection for your home. The shroud will prevent accidental damage to the cable and will stop fires.

Protection hoses can be plastic or metal, which type to choose depends on the specific situation and the type of wiring. The installation of the corrugation is not difficult and can be done by hand.