How to choose a wood preservative: helpful tips

Wood is one of the most common building and construction materials. However, wood is very sensitive to external influences, in particular, to atmospheric factors and biological damage. All of these threats are confronted with a wide range of antiseptics. In this article, we will tell you how to choose a wood preservative, consider their varieties, advantages and disadvantages, and give a brief overview of the main manufacturers and their products. Let's describe the main methods of application and typical mistakes made in this case.

One of the main conditions for increasing the service life of wooden structures is their treatment with antiseptic substances.

PHOTO: remoo.ru

The content of the article

- 1 The principle of operation and advantages of using an antiseptic

- 2 Classification of wood preservatives

- 3 Popular manufacturers

- 4 The best antiseptics and the specificity of their use

- 5 The choice of antiseptic preparations for wood

- 6 Wood treatment methods with antiseptic

- 7 General recommendations for use

- 8 conclusions

- 9 Video: how to choose a wood preservative

The principle of operation and advantages of using an antiseptic

To prevent or minimize negative external influences, timber treated with special compounds - antiseptics. However, wooden structures are operated with fluctuations in temperature and humidity, ultraviolet radiation. In addition, the list of diseases and pests is also very diverse:

- wood-destroying and wood-coloring fungi (saprophytes);

- algae - stain and deform the outer shell;

- bacteria - initiate putrefactive processes;

- bark beetles, grinders, woodcutting beetles.

Almost all antiseptic agents contain the following active substances:

- oxidants - destroy the fungus at the cellular level;

- fungicides - they block putrefactive processes and the effect of enzymes secreted by the fungus, have a toxic effect on insects.

All antiseptics are produced in the form of liquid emulsions. The better the penetration effect of the composition, the higher the level of protection it provides.

The use of antiseptics significantly improves the performance of wood and provides the following benefits:

- protection of building structures from damage caused by insects and rot;

- prevention of the appearance of spots (blue, fungus) on the surface;

- reducing the likelihood of cracking;

- increased adhesion to paint and varnish finishing materials.

Classification of wood preservatives

Wood preservatives on the market are classified according to the following characteristics:

- base type;

- appointment;

- application area.

Base type (composition)

Depending on the base material, there are several types of antiseptics.

- Water soluble... Have the least pronounced effect. It is recommended to treat those parts of building structures that will subsequently not be exposed to direct environmental influences, as well as excessive influences humidity... Sometimes after processing the wood can warp and crack.

- Oil... They maximally protect wood from moisture. They significantly increase the combustibility of structures, emit an unpleasant odor that can remain in the room for quite a long time. Some compounds change the color of the base.

- Organic... Antiseptics based on organic solvents are used both inside and outside buildings. A thin film is formed on the treated surface, which significantly increases the adhesion properties of the base.

Appointment

Depending on the main purpose, there are two main types of antiseptic agents.

- Preventive... They are used before the wood is used in structural elements. As a rule, they are applied after the primary processing of sawn timber at the final stage of autoclaving. However, there are a number of formulations for home use. Such funds are the most persistent and aggressive, therefore it is recommended to use them outside the structures. In the case of use for internal work, adhere to the recommended technological pause. They are used once every 5-7 years.

- Therapeutic... They are used at the stage of damage to wooden structures by fungus, microorganisms, insects or rot. They are often used for preventive purposes, if wood will be part of structures that are exposed to intense negative effects.

Application area

Depending on the area of application, antiseptics are usually divided into two types:

- for internal processing;

- for outdoor work.

For internal work, a dense film is formed on the surface of the base, blocking the entry of chemicals into the atmosphere. Resistant to external influences, including abrasion, high humidity and household chemicals. Usually such funds are distinguished by their high cost.

Wooden structures of premises with variable temperature and humidity conditions are especially in need of antiseptic treatment

PHOTO: encrypted-tbn0.gstatic.com

For external work, they are distinguished by a high concentration of active substances. Often they have an unpleasant odor that does not disappear even after complete drying. It takes 1.5-2 months to weather it.

Popular manufacturers

There are many formulations from various manufacturers on the construction chemistry market. Many of them are affordable and promise the user protection of wood from almost all types of lesions. However, such products can be aggressive and hazardous to human health through daily contact.Safe and effective means of protection are usually produced by branded companies specializing in paints and varnishes and construction chemicals.

- AkzoNobel (Netherlands) Is a manufacturing company that owns the Pinotex trademark. It specializes in the production of paints and varnishes and wood protective coatings.

- Tikkurila (Finland) - a large manufacturer of high quality paint from Finland. It is presented in three main brands TIKKURILA, TEX, FINNCOLOR.

- MEFFERT AG (Germany) - Dufa trademark. Specializes in environmentally friendly repair and finishing materials, including paints, varnishes, enamels, primers and wood protective coatings.

- NORT (Russia) - trademarks Pirilax, Nortex, Krasula, a leading Russian manufacturer of antiseptics, fire-bio-protective agents and protective and decorative compounds.

- Belinka Belles (Slovenia) - Belinka trademark. It is part of the international Helios concern. It specializes in the production of premium protective and protective-decorative compounds.

- Senezh (Russia) - the brand specializes in the development and production of a full range of wood preservatives.

The best antiseptics and the specificity of their use

In an effort to provide maximum protection of wood from various external factors, manufacturers have developed many universal and specialized formulations.

With the effect of bleaching wood. They restore the natural color and texture of the affected areas, prevent the formation and spread of saprophytes. Bioshield 1/2 (Latek), Standard, Pro, Light (Sagus) - for household use. Prosept 50, Neomid 440/430 Eco - concentrates with whitening and healing effects.

Protective agent against mold, parasitic microflora, fungus. PAF-LST, Senezh-BIO, (Senezh) Base, Impregnant, Belocid, Belbor fix (Belinka) It is produced both in ready-to-use solutions and in concentrates.

Universal means of biofire protection - Ognebio Prof and Senezh Ognebio (Senezh), Neomid 450-1 / 450 (Neomid).

Antiseptics with additional UV protection - Senezh Aquadecor (Senezh), Biofa 2108 (BIOFA).

Antiseptics with moisture protection effect for outdoor use - Valtti Aquakolor (Tikkurila), Pinotex Terrace Oil (Akzonobel).

Moisture-repellent effect after treatment with antiseptic impregnations

PHOTO: encrypted-tbn0.gstatic.com

Moisture-protective antiseptics for wet rooms (baths, saunas) - KRASULA (NPO NORT LLC), Senezh Insa, Senezh Trans (Senezh), Neomid 46/420 (Neomid), Prosept-46.

Antiseptic impregnation for a bath, in addition to magnetic properties, is resistant to high temperatures and humidity

PHOTO tiu.ru

The choice of antiseptic preparations for wood

For the most effective protection of building structures made of wood, it is necessary to select the optimal type of antiseptic impregnation. To do this, you need to analyze a number of important characteristics, which are listed below.

Method and degree of exposure. Distinguish between universal and specialized formulations with additional effects. For domestic use and in private construction, universal compounds are usually used that protect against a wide range of biological lesions. However, they are rather an addition to the main method of wood protection - painting or plastering. Specialized tools are more effective, but more expensive.

External effect. Depending on the characteristics of external influence on wood, the following types of impregnation are distinguished:

- neutral - after processing the tree does not change in any way;

- pigmenting - have a coloring effect from a slight change in shade to a significant change in color;

- creating an outer coating, which form a dense moisture-repellent layer on the treated surface.

When treated with an antiseptic, the wood is stained, which helps to identify untreated areas

PHOTO fortinvest.ibud.ua

By the degree of penetration.There are external compounds that penetrate into the fibers by no more than 2-3 mm, and deep penetration impregnations that penetrate into the material up to 10 mm. It should be remembered about the own hygroscopicity of wood species:

- easy impregnation - pine, birch, beech;

- moderate hygroscopicity - aspen, maple, linden;

- low absorbency - oak, ash, spruce.

Wood treatment methods with antiseptic

All antiseptic agents are sold in the form of liquid formulations, concentrates that must be diluted with water, or ready-made emulsions. They can be applied in several ways, similar to paints and varnishes.

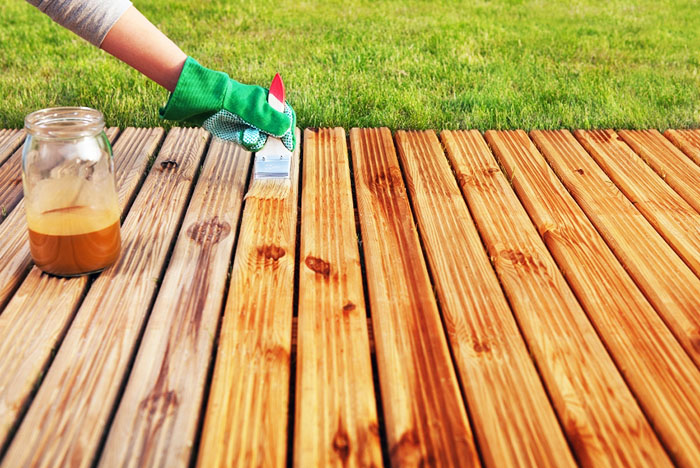

Brush

Applying an antiseptic with a paint brush is a rather lengthy but most economical treatment. It makes it possible to qualitatively cover corners, joints of parts and hard-to-reach areas with a liquid composition. Recommended for small surfaces. It is allowed to use for antiseptic mixtures of any type, both deep penetration and external.

Brushing is one of the easiest processing methods and can be done with your own hands.

PHOTO: astroyresurs.ru

Roller

It is used when processing medium-sized structures with a flat and straight surface. It is recommended to use thread or fur rollers. Usually, with their help, matting or coloring impregnations are applied. When performing work, use a plastic tray to ensure uniform application.

Spray

Designed for processing large areas. With its help, it is possible to process both flat surfaces and structures of complex shape with a uniform layer. Antiseptic consumption is slightly higher than with manual processing.

With the help of sprayers, impregnations are most often applied on a water and organic basis.

PHOTO: azurka.ru

Immersion

This option provides a high degree of protection for timber structures. Not only small parts are processed this way. To immerse long products (boards, beams, beams) directly at the construction site, a trench is dug in the ground, laid out with a film and filled with an antiseptic. The disadvantage of this method is the high consumption of antiseptic substances.

Autoclaving

Provides maximum protection. The antiseptic penetrates deep into the wood under pressure. It is used exclusively in enterprises.

Impregnation of lumber with an antiseptic in an autoclave guarantees maximum protection against biological corrosion

PHOTO autoclave.com

General recommendations for use

In order for the effect of antiseptic agents on wood to be as effective as possible, treatment should be carried out in accordance with the following recommendations:

- optimal temperature range + 10 ° С ... + 30 ° С, humidity no more than 40%;

- apply at least two, but preferably three layers of antiseptic. In this case, the subsequent ones are applied only after the previous ones have completely dried;

- the antiseptic agent must completely cover all areas of the wooden structure. You cannot leave untreated places, as in the future biological contamination will spread from them;

- further decorative finishing (application of paints and varnishes or wax) should be started immediately after the antiseptic has dried. This ensures better adhesion and protection efficiency.

Important! Modern manufacturers are developing and offering more and more new types of antiseptics, including those that can be used at negative temperatures and high humidity. Such compositions are an order of magnitude more expensive, and some of them require special preparation of the base or the antiseptic solution itself.It is highly recommended to buy such special antiseptic formulations only from trusted manufacturers.

conclusions

Wood treatment with an antiseptic is the main way to increase the service life of wooden building structures. In addition, modern antiseptic compositions make it possible to restore the original appearance of some affected areas, and can also act as decorative coatings.