Copper pipes and fittings for plumbing in residential buildings

HDespite the ubiquitous use of polymers in plumbing and plumbing systems, reliable and proven copper still does not give up its positions. Although copper pipes and fittings for water supply are much more expensive than others, they have a whole set of advantages in comparison with their polypropylene and metal-plastic counterparts.

The content of the article

Copper plumbing systems

Copper is a ductile and durable metal that does not corrode, and is also resistant to lime deposits and the development of microbes. Its strength and ease of processing have made it the most popular among other metals.

Copper piping

Copper pipes, according to the standards, have thin walls, which makes them easy to bend. For cutting and bending, special tools are used that do not crush the pipe and allow you to get an even cut without chipping. Due to the particular resistance to high temperatures, it is advisable to use copper pipes and fittings for hot water supply.

This metal has a very high thermal conductivity, which causes the tube to become very hot from the outside. Such communications must necessarily be closed with a casing or mounted in special boxes. At the same time, the water pipe looks very aesthetically pleasing and is used by many as a stylish element. interior.

Copper pipe fittings

For copper pipes, various types of fittings can be used, including brass. There are several types of fastening of connecting elements, the choice of material from which they are made depends on this.

If fittings with pipes are connected by welding, then it is obvious that both must be made of the same material. For installation work, you will need special equipment, solder, flux and certain skills.

Crimp systems require fittings to be made of a sufficiently ductile material such as copper.In addition, due to the same coefficients of thermal expansion, the formation of leaks and crevices is excluded.

Popular collet fasteners, which are equally successfully used in both metal-plastic and copper pipelines, are present in brass fittings. Brass is an alloy of zinc and copper, to which nickel, lead, iron and other alloying additives are added for strength, while the percentage of copper is at least 60%. Whereas for welded and crimp connections only a smooth tube cut is needed, the collet connection requires an external thread. This assumes that the wall thickness of the copper pipe will be higher.

Threaded fittings are the easiest option in terms of installation. Fittings can be made of either copper or brass, there are no special instructions here.

Application of copper fittings

Copper water pipes are much more expensive than plastic, steel, or aluminum. There are supporters and opponents of the use of this material, each of which has its own arguments. Among the advantages of pipelines made of this expensive metal, the following can be noted:

- high corrosion resistance, subject to correct installation, because a thin film of greenish copper oxide forms on the pipe walls, which prevents destruction and serves as a kind of anti-corrosion layer;

- copper pipelines prevent the accumulation of lime, thus, the pipe lumen and its thermal conductivity do not change over time;

- the service life of a copper pipeline is on average 100 years;

- copper ions have antimicrobial effect, which allows the water in the system to remain clean;

- copper begins to melt only at temperatures above a thousand degrees, and temperatures in the system up to 600 degrees do not experience any changes at all;

- The strength of the metal allows copper pipes and plumbing fittings to withstand water hammer without damage.

However, copper is not perfect, it also has significant disadvantages:

- fittings and other elements must be made of either copper or chemically neutral material, otherwise corrosion of the copper pipe is inevitable;

- metal pipes in apartment buildings are often used to grounding, however, in case of incorrect connection using in the immediate vicinity of the potential source of aluminum and steel fittings, a galvanic pair is formed, which inevitably leads to corrosion;

- the service life of copper pipes may be longer than the service life of a residential apartment building itself.

Installation features

Fittings are used not only for branching and tapping shut-off valves. Masters recommend using them for the formation of bends and turns, since bending the pipe can lead to the formation of creases, and subsequently microcracks.

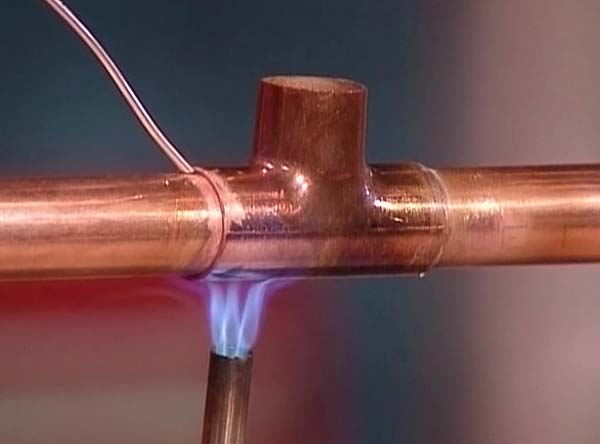

Welding - performed only by a specialist using a blowtorch or a special electric soldering device for pipes by capillary soldering. A special composition of solder is used: silver, copper-phosphorus and copper-silver-zinc, as well as a special flux. Special copper materials have a high flowability, which is required for capillary brazing.

Crimp – the installation of the connection is carried out using a special adjustable wrench; it is permissible to use polymer sealants or rubber and silicone gaskets as a seal, corresponding to the temperature regime.

Thread is a method that has a limitation due to the nature of the material: the thread on the pipe is cut only from the outside. Installation is carried out using a sealant.

The collet is a reliable and durable system that consists of a compression nut and an O-ring, which create an easy-to-install and extremely reliable connection.

When to choose copper fittings

Based on the known features of the material, copper pipes and fittings for water supply can be used if the following conditions are met:

- the system excludes the appearance of large particles of sand or other abrasive that can damage the soft metal from the inside;

- the installation of the pipeline was carried out without the use of aluminum and steel parts, since it is impossible to exclude the possibility of the appearance of an electric potential on the pipe in an apartment building.

For copper, these two conditions are defining and exhaustive, since parameters such as system pressure, water temperature and the possibility of water hammer for copper pipelines are not important.

Video: brazing copper fittings