Why do you need a water pump check valve?

In order for the water supply system in a private house to function correctly, it is necessary to correctly install it, not missing the little things. For example, an unobtrusive but very important device is a water check valve for a pump. If this element is missing or becomes unusable, then the water pumping station system will not work correctly. Water will flow into the house with a noticeable delay, the pressure will be poor, and if the pump is weak, it will completely disappear. The presence of the valve allows you to get water instantly after you turn on the tap.

The content of the article

- 1 Water check valve for pump: principle of operation

- 2 Check valves for pumping stations: design types

- 3 Check valve spring coupling: types by material

- 4 Check valves for submersible pumps: installation rules

- 5 Water check valve prices for pump: manufacturers review

- 6 Tips & Tricks

- 7 conclusions

- 8 Video: product overview and purpose

Water check valve for pump: principle of operation

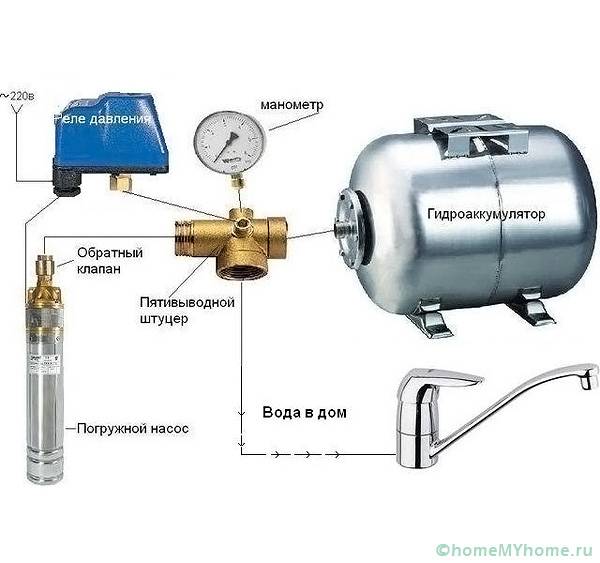

This device is most often installed at special stations that are included in the water supply system. The task of this element of the system is to prevent mixing of water. It works according to the following principle: the liquid can pass only in one direction, it cannot go to the opposite part of the pipe. This is necessary so that water from a well or well cannot come back and be directed into the water supply system. If the system is equipped with such a valve, then when you open the tap, you do not need to wait for the pump to pump water: it will pour out immediately. In the absence of a device, air accumulates in the system, and you have to first release it, waiting for the water to flow.

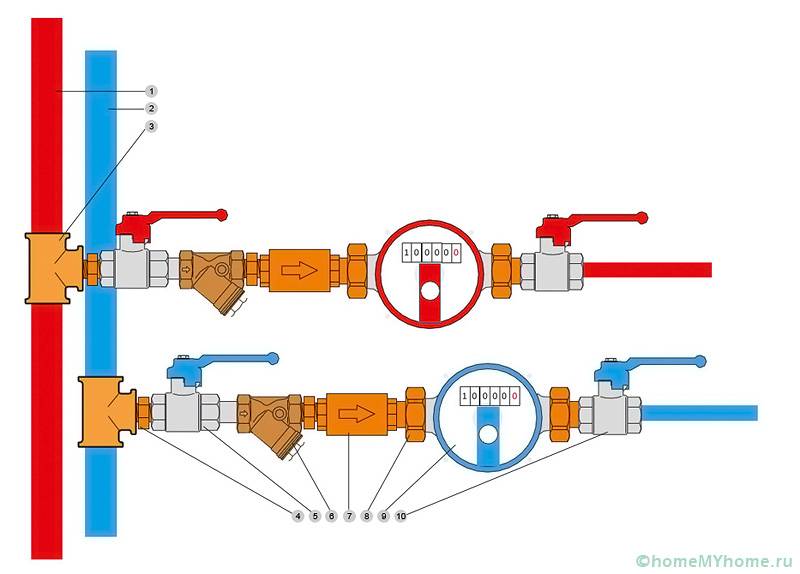

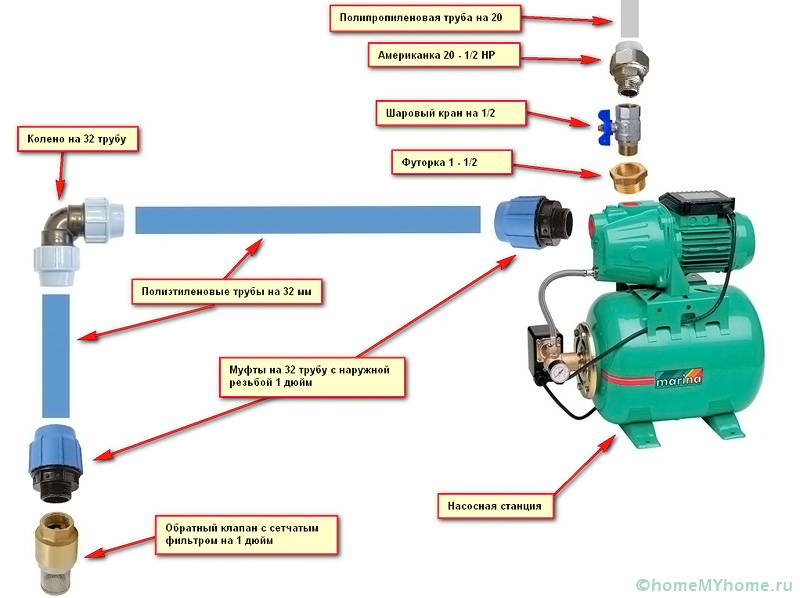

The station itself can be located both on the surface of a well or well, and in a specially designated place in the house. In this case, a pipe equipped with a debris mesh and a water check valve for the pump will be lowered into the well.

If the pump is used in a city apartment, then this element allows you to avoid the effect when, when opening one tap, the pressure drops in the other. This design in the apartment will not hurt if installation is planned boiler... It will need to be mounted not only on a cold, but also hot water riser. This will help prevent loss of heated fluid.Without this device, some of your water will go to the neighbors who live on the floor below. Thus, the check valve saves energy as it saves the system from unnecessary losses.

Check valves for pumping stations: design types

On sale you can find a large number of similar devices that differ in design, material, size, and each has its own characteristics during installation:

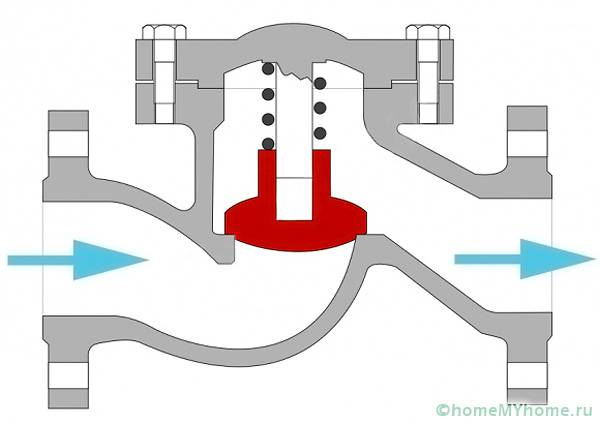

- A water check valve for a pump can most often be found with a lifting-type locking element. The device is equipped with a shutter that moves up or down, preventing the movement of water. When water enters, the valve rises and lets it through, and when the pressure drops, the valve drops and does not allow fluid to return. The mechanism moves thanks to a special spring.

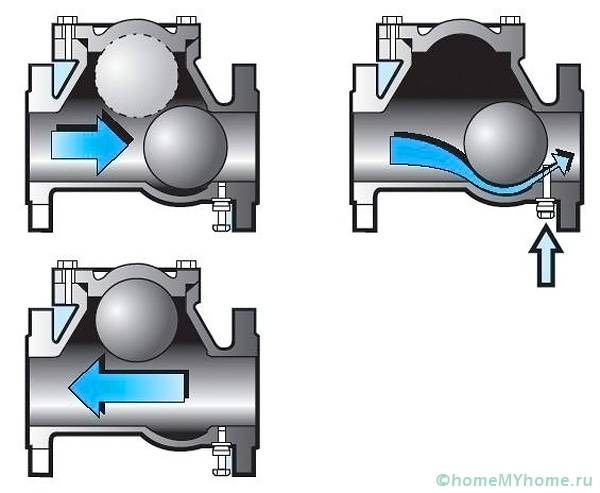

- Return parts for ball pump. This type of device has a ball-shaped seal that blocks the path of the liquid. With the pressure of the water pressure, the spring lifts the ball, and the system lets water through, and after the pressure drops, the element closes.

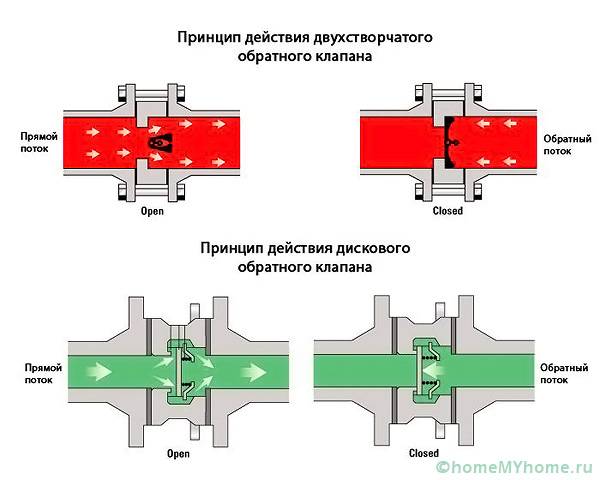

- Disc element. It has a disc-shaped shutter that moves along its axis by means of a spring.

- Bivalve devices. Their shutter has two flaps, which fold under water pressure, and when there is no pressure, they close; all this is driven by a spring.

In everyday life, a part with a lifting type of mechanism is most often used. It can be repaired by replacing the spring.

Check valve spring coupling: types by material

Products can be made from different materials:

- Brass is the most popular material. It does not rust, is easy to maintain, and fits well with all types of pipes.

- Cast iron cases are much less common. This material corrodes, various deposits accumulate on it quite quickly. Usually cast iron products are used on pipes of large diameter, and they are not used in everyday life.

- Stainless steel. It is the most reliable, but also the most expensive material: its elements will last much longer than any others. They are not afraid of corrosion and the effects of various substances; deposits do not accumulate on the body.

- Combined: the body of such a product can be made of different materials, for example, combine brass and stainless steel. The shutter of any device is most often made of plastic.

Helpful information! When choosing a valve for home use, buy a brass one. It serves for a long time, and its cost is much lower than steel.

Differences in mounting method

Most devices are attached with a sleeve. This requires two threaded transitions to match the size of the pipeline. Flanged mountings can also be used. Most often they have large diameter cast iron elements. These flanges are bolted together. This type of fixation is also relevant for small products when there is no room for other fixing on the pipe.

The spring loaded check valve is the most commonly used. It is used in apartments for installation on a pipeline, a water heater, such products are installed after the meter, which does not allow it to spin in the other direction. Devices of this type prevent the pipes from emptying if the water in the riser is drained.

Spring mechanism device: it consists of a brass body that can be disassembled into two parts. A movable spool is placed between the halves. It's usually made of plastic. Such a spool is driven by water pressure and a spring.

Related article:

Why do you need a water pressure regulator? In a separate publication you will find useful information about this device: principle of operation, purpose, prices, etc.

Check valves for submersible pumps: installation rules

Before starting the installation, you need to choose the right place where the part will be installed. The location is dictated by the type of submersible pump. You can pick up any element, it will interact with the device, regardless of its type, brand and model. This is due to the fact that the principle of operation of the equipment is the same. It is quite possible to replace check valves for submersible pumps yourself, for this you will need to carefully study the proposed material.

Most pumps are already equipped with the required part from the factory. There is such a device at both the inlet and outlet. Additional devices are not required for such devices.

If you purchased a vacuum pump, then the check valve must be installed in front of the accumulator, but after the unit itself. Ball or spool fittings work best with this type. If the pump is superficial, it can have several such elements at once. One of them is installed in the hose through which the water flows. The part must be placed at the end of the hose, which is lowered into the water. The second element is mounted in front of the accumulator. Any type of product is suitable for such a device. Some models are an exception; the manufacturer indicates in the instructions for the device which are required.

In order to install the reverse element, you will need to cut it into the pipe. To do this, you need to purchase fittings and couplings. Before starting work, the water must be shut off or the system must be stopped so that the water flows do not interfere. Then the desired element is cut into the right place.

Helpful information! You can make the fixation more durable using fum tape. Make sure the element is facing the right way, otherwise it will not work. If it is lifting, check if the axle is vertical.

Elements for pumping stations are installed after the ratchet. Place them on the main suction pipe. It is possible to install it directly in front of the station, but this option is inferior to the first in quality, since in this case the amount of water can be significantly reduced.

The pipe can be filled not only with water, but also with air, which is sucked in by the pump. Air trapped in the system will make it noisy. If the station uses a vibrating pump, the valve is best placed in front of the receiver. You can choose for this any place in the injection pipe, but it is advisable to place it in a place accessible for maintenance.

The object is most often mounted in front of the station. When installed on a running system, it needs to be positioned between the pump and the station. The same is done if the system has a receiver. The pipeline is divided into two parts, on one of which a valve is placed. Then, using a squeeze, the pipes are connected again.

You can familiarize yourself with the installation process for different types of equipment below:

Water check valve prices for pump: manufacturers review

| Name | Diameter, mm | Average price by region, RUB |

|---|---|---|

| Polypropylene product | ||

| AQUA-S | 20 25 32 | 120 150 220 |

| VALTEC | 20 25 32 | 150 170 300 |

| With spring clutch | ||

| Danfoss CO | 15 20 25 | 500 800 1000 |

| VALTEC | 15 20 25 | 200 300 420 |

| Teсofi | 15 20 25 | 300 460 600 |

| ITAP | 15 20 25 | 400 500 700 |

| With brass spool and coupling | ||

| VALTEC | 15 20 25 | 250 200 520 |

Tips & Tricks

When choosing a check valve, you need to take into account the system on which it will be installed. Also, do not purchase too cheap products from little-known companies: a water check valve for a pump, the price of which is understated, may require an early replacement. Better to pay a little more, but buy proven products.

conclusions

- A check valve is necessary for the stable operation of the water supply system.

- With this simple device, you do not have to wait while the pump pumps water into the pipe.

- The pipes will not fill with air.

- A water check valve will help save energy, as it will prevent the loss of warm water if you install it, for example, on a water heater pipe.

- With this device, you can use water for some time, even if the pump is turned off.

Video: product overview and purpose