Step-down transformer 220 for 12 volts: types and options for use, how to choose and make your own hands

Among electrical devices for converting electrical energy, transformers are the most famous and widespread structural element. Power models are used in electrical networks of various voltages, and low-power models are used in control and switching circuits, as well as in low-current networks and for connecting various electronic equipment. A 220 12 Volt step-down transformer - what is it for, and how the various types are arranged, how to connect and check, and also make it yourself - this is the topic of this article at homemaster.techinfolux.com/en/.

The content of the article

- 1 What is a step-down transformer from 220 to 12 volts for?

- 2 Classification and types

- 3 Device and principle of operation

- 4 Main technical characteristics

- 5 How to choose a transformer for a chandelier

- 6 How to connect a step-down transformer

- 7 How to check a step-down transformer

- 8 Making a step-down transformer from 220 to 12 volts with your own hands

- 9 How much and where to buy a 220/12 Volt step-down transformer - price overview

- 10 Video: step-down transformer: how to choose and connect

What is a step-down transformer from 220 to 12 volts for?

The main purpose of a step-down transformer is to convert a primary voltage of 220 Volts into a secondary voltage of 12 Volts, which is used to:

- connecting light sourcesoperating at a voltage of 12 volts (LED lamps and strips, incandescent lamps and halogen light sources, as well as other lighting devices);

- creating an electrical network in rooms where, according to safety rules, the voltage of a household electrical network (220/380 Volts) cannot be used;

- connection of low-current systems (CCTV, alarm, etc.) operating at low DC voltage.

Classification and types

Step-down transformers are classified according to several parameters:

- by design - electromagnetic and pulse;

- by technical characteristics - electric power, maximum allowable for load connection;

- by type of execution - open or placed in a protective case;

- by type of use - household and industrial.

The most noticeable difference that determines the possibility of using and applying step-down transformers with a voltage of 220/12 Volt is their design.

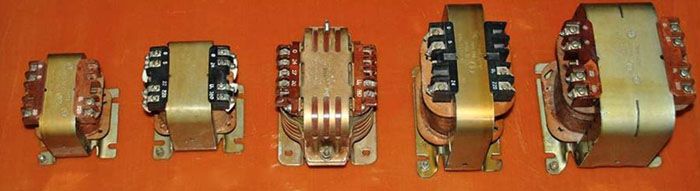

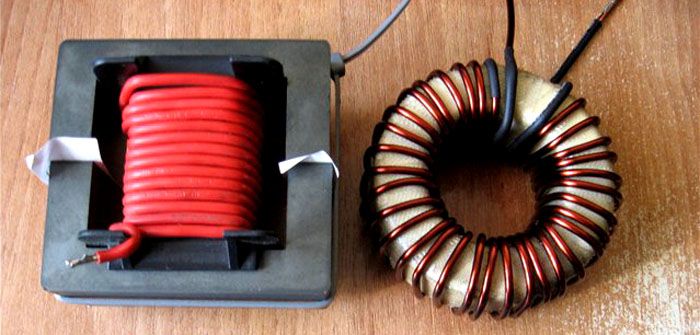

Toroidal (electromagnetic) models

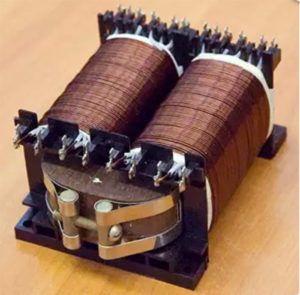

A toroidal (electromagnetic) transformer 220 to 12 Volts is a classic version of such devices. The design of electromagnetic models is a core made of special types of steel, on which the primary and secondary windings are wound. The transformation of electrical energy occurs due to the electromagnetic force generated in the body of the core.

The advantages of the design are:

- reliability;

- a variety of models with different technical characteristics and types of execution;

- relatively low cost.

The disadvantages include:

- heavy weight;

- sensitivity to power surges in the power supply network.

Electronic (pulse) models

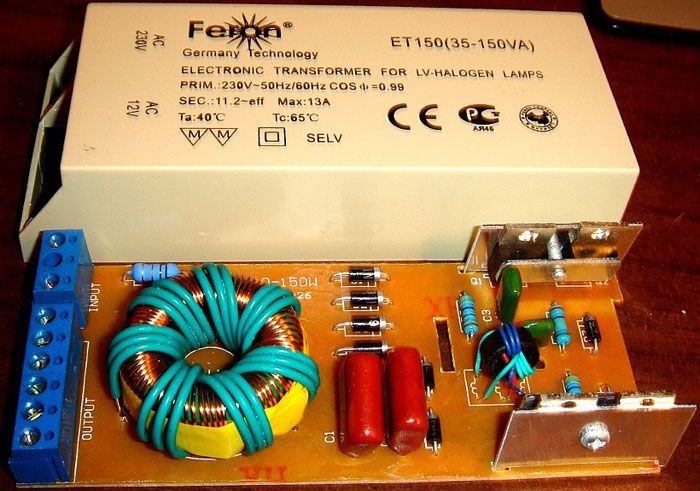

Pulse models are assembled from electronic components, which significantly expands the capabilities of step-down transformers of this type.

The advantages of electronic devices are:

- small overall dimensions and low weight;

- resistance to voltage drops in the supply network;

- stability of voltage values at the output of the device;

- smooth start when turned on and high power factor indicators.

The design of this type is based on a ferrite core with an electrical winding made on it, as well as transistors, diodes and other electronic components.

Device and principle of operation

Electronic and electromagnetic models of transformers differ both in their design and in the principle of operation, therefore they should be considered separately:

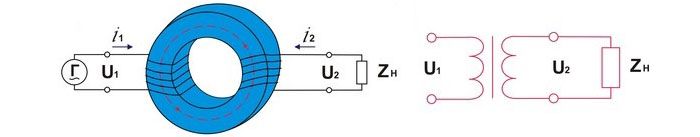

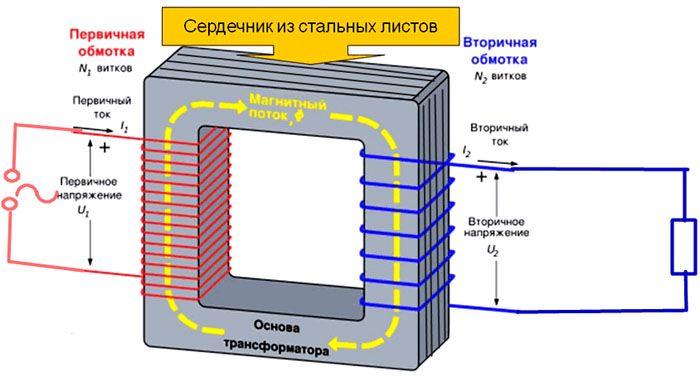

- Electromagnetic transformer.

As already written above, the basis of this design is a toroidal core made of electrical steel, on which the primary and secondary windings are wound. There is no electrical contact between the windings, the connection between them is carried out by means of an electromagnetic field, the action of which is due to the phenomenon of electromagnetic induction. The diagram of a step-down electromagnetic transformer is shown in the figure below, where:

- the primary winding is connected to a 220 Volt network (U1 on the diagram) and an electric current flows in it "i1»;

- when voltage is applied to the primary winding, an electromotive force (EMF) is formed in the core;

- EMF creates a potential difference on the secondary winding (U2 on the diagram) and as a consequence - the presence of electric current "i2»With a connected load (Zn on the diagram).

The specified value of the voltage on the secondary winding is created by winding a certain number of turns of wire on the core of the device.

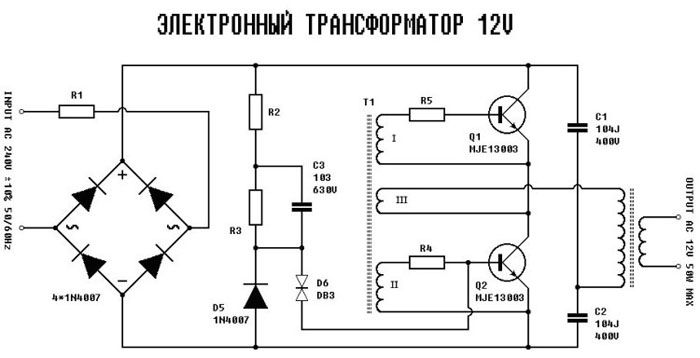

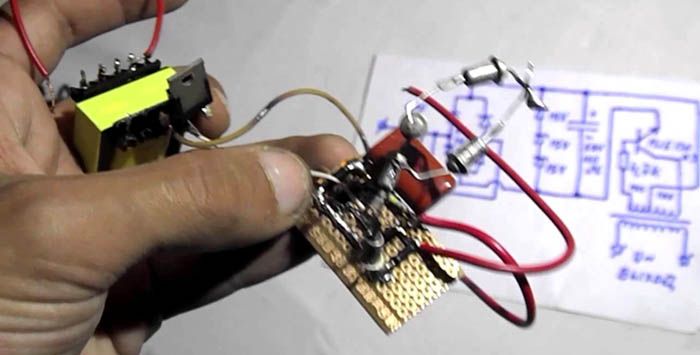

- Electronic transformer.

The design of such models provides for the presence of electronic components, through which the voltage is converted. In the diagram below, the mains voltage is applied to the device input (INPUT), after which it is converted by means of a diode bridge into a constant voltage, on which the electronic components of the device operate.

The control transformer is wound on a ferrite ring (windings I, II and III), and it is its windings that control the operation of the transistors, and also provide communication with the output transformer, which outputs the converted voltage to the output of the device (OUTPUT).In addition, the circuit contains capacitors that provide the required voltage output waveform.

The above circuit of an electronic transformer can be used to connect halogen lamps and other light sources operating at a voltage of 12 volts.

Main technical characteristics

Technical characteristics determine the possibilities of using a step-down transformer, as well as the conditions for its operation, which is expressed in the following indicators:

- rated primary voltage;

- rated power;

- mode and conditions of use;

- degree of protection according to GOST 14254-96;

- body material (if any).

How to choose a transformer for a chandelier

Chandelier Is a type of pendant luminaire, the design of which provides for the installation of several light sources (lamps). If earlier there were only incandescent lamps as light sources installed in chandeliers, then the question of choosing a step-down transformer for such lighting products did not arise at all. Today, in connection with the introduction of energy-saving technologies, chandeliers equipped with energy-efficient light sources are becoming more widespread. In this case, the question of choosing a transformer becomes very relevant.

When choosing a step-down transformer designed to connect halogen or LED lamps, you should pay attention to:

- rated voltage for which the installed light sources are designed;

- the power of all installed lamps provided for placement in one luminaire must correspond to the rated power of the transformer.

In addition, when choosing a voltage converter, it is necessary to pay attention to its weight and overall dimensions, which allow placing the device in the lamp (chandelier) body.

How to connect a step-down transformer

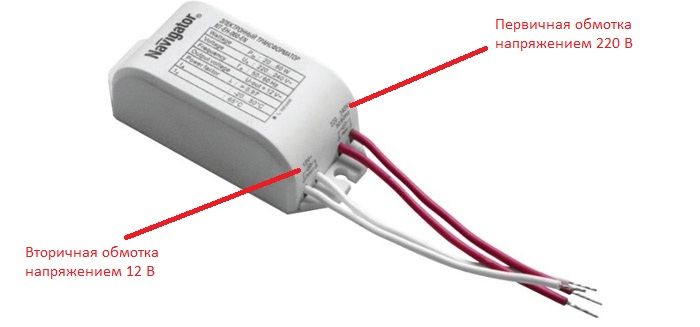

There should be no problems with connecting such equipment, even for a person who is very far from electrical engineering. The reason for this is the marking applied to the case of the step-down transformer and indicating which terminals should be connected to the wires from the power supply network, and to which - the load. The phase wire is connected to the "L" or "220" terminal, and the zero wire - to "N" or "0", which depends on the type of marking chosen by the manufacturer.

Marking of the terminals of the primary and secondary winding on a step-down transformer of an electronic type designed for connecting light sources

How to check a step-down transformer

In order to check the health and performance of the step-down transformer, you will need multimeter (tester) - a combined electrical measuring device. If there is no marking on the transformer, then the ends of both windings are initially determined. For this, the tester probes are applied to the lead terminals (wires) of the device under test, while the multimeter is used in resistance measurement mode... When the ends of the windings are marked, it is determined which one is primary and which is secondary. For this, the values of resistances in the windings are studied, in the primary it will be greater, in the secondary - less.

In the presence of a larger number of windings, the work is carried out in the same way, with the only difference that it becomes necessary to call a larger number of conclusions. To test the operability, voltage is applied to the primary winding, and a load is connected to the secondary in the form of a light source of the corresponding voltage class.

Related article:

In the publication we will consider how to use a multimeter correctlyhow the device is arranged, the principle of operation, what varieties exist, the recommendations of specialists.

Making a step-down transformer from 220 to 12 volts with your own hands

Currently, you can find on sale any step-down transformer that meets all the requirements for this type of technical device. Nevertheless, for people who have a creative streak and want to make everything with their own hands, it is quite possible to assemble a step-down transformer with their own hands. All work on the independent manufacture of such a product can be divided into several stages: preparatory, work execution and performance check.

Preparatory stage

At this stage, you should:

- decide on the type of the assembled device - electromagnetic or electronic;

- determine the technical parameters required for further use - power and installation location, permissible dimensions and weight;

- calculate the parameters of the primary and secondary winding, in the case of the manufacture of an electromagnetic model;

- purchase the necessary materials and components.

In the manufacture of an electronic device, skills in working with soldering iron and basic knowledge of electronics. In this case, the circuit of the device is initially selected, and, accordingly, electronic components (transistors, capacitors and others) are prepared for it. In the case of the manufacture of an electromagnetic model, you will first need to calculate the windings of the assembled device, and then perform all other operations.

To determine the number of turns N1 in the primary winding, you must use the formula:

N1 = (40 - 60) / Swhere

- S - cross-section of the magnetic circuit (core) of the transformer, measured in cm2;

- 40–60 Is an indicator (constant) that determines the type and quality of the core.

The cross-section of the core is determined based on the geometric dimensions of the blanks used: the window, the width and thickness of the core cheeks. The cross-section of the wire in the primary winding must correspond to the current that will flow in it during operation, which is determined by the size of the connected load, in numerical terms it is defined as:

I1 = P / Uwhere

- I1 - the current flowing in the primary winding;

- P - power of the connected load;

- U - voltage on the primary winding.

Accordingly, knowing the value of the current flowing through the wires, you can choose their permissible cross-section, in accordance with the requirements regulated by the Electrical Installation Rules (PUE). The cross-section of the wire for the secondary winding is determined in the same way.

The number of turns in each of the windings is determined by the formula:

W = U × (V / 10)where

- W - the number of turns in the winding;

- U - voltage in the transformer winding;

- V - electric current frequency - 50 Hz.

Having decided on the number of turns, and therefore on the dimensions of the core, as well as the required length and cross-section of the wire in both windings, you can prepare the necessary materials to perform the work:

- wire for both windings;

- core - you can purchase a new one or use it from used equipment (TV, radio, etc.);

- insulating materials (tape, paper and others).

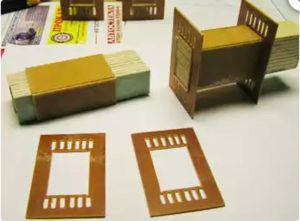

In addition, it is possible to manufacture a winding machine that facilitates the production of windings, in the case of the variant when the windings are made in the form of coils placed on the core.

Execution of works

When all the preparatory measures have been completed, you can start manufacturing and assembling the transformer, in this case, the work is performed as follows:

Functional check

When the transformer is assembled, and all its components are securely fixed and insulated, it is necessary to check its performance. To do this, a voltage of 220 volts is applied to the primary winding, and a load is connected to the secondary winding, designed to work at a voltage of 12 volts.

If the test is successful, the assembled product is placed in a prepared enclosure or installed in a designated location.

How much and where to buy a 220/12 Volt step-down transformer - price overview

The price of transformers 220 for 12 Volts depends on their technical characteristics, purpose and degree of protection, as well as the place of their sale. These products can be bought in lighting and electrical stores, retail chains of various equipment and building materials, as well as on the Internet.

In the departments of lighting and electrical products, step-down transformers of various brands and designs are always on sale

The following table shows the cost of various models of step-down transformers when sold through the Internet, as of the II quarter of 2018.

The availability of various models, differing in technical characteristics, dimensions and operating conditions, allows you to choose a step-down transformer in accordance with the requirements for it in different price ranges.

Currently, it is not difficult to buy a voltage converter, the main thing is to make the right choice in the variety of offers on the market of electrical products