Wood varnish: how to choose the right look for maximum effect

Wood is a popular building and decorative finishing material. Furniture, household items and decor are made from it. However, all wood species, to a certain extent, are subject to the negative influence of the external environment, especially humidity and biological corrosion (mold, rot, fungus). Various substances are used to protect wood products and extend the life of wood structures. Varnish is one of the most effective. In this article we will tell you how to choose a varnish for wood, characterize its main varieties in composition, consider the advantages and disadvantages, selection criteria, present a list of the most popular manufacturers of paints and varnishes, compiled according to user reviews.

The content of the article

Classification of varnishes for wood by composition

According to regulatory documents, varnishes are called mixtures (as a rule, they have high viscosity) based on various solvents, the active substance of which is synthetic (polymer) or organic resins. The main classification is made according to the composition that determines the scope.

Oil

They were created first back in the XI century. Initially, resins and oils of natural origin were used for their manufacture. With the advent of polymer resins and synthetic oils, the cost of such products has significantly decreased, and its technical parameters have increased. Depending on the percentage of oils in the mixture, the following brands are distinguished:

- skinny - up to 55%;

- medium - 55-65%;

- fatty - up to 85%.

Greasy oil varnishes have the best performance characteristics. They provide the best protection and have excellent decorative properties. Typically used for the treatment of solid wood flooring in residential areas with low to medium traffic.

On the negative side, one can note the high viscosity and density of fatty and medium compositions, limited shelf life: no more than a year in a closed container and several days after opening the original packaging. Long drying period: 1-3 days.

The time-consuming process of application with a brush can be slightly facilitated by diluting the composition with water, but not more than 5% of the total volume.

Alkyd

To form the base, synthetic resins (glyphthalic or pentaphthalic), organic solvents, mainly white spirit and solvent are used. Some brands add desiccants to speed up drying. Alkyd varnishes for wood form a wear and abrasion resistant surface. They reveal and accentuate texture and have other benefits:

- affordable cost;

- resistance to moisture;

- resistance to temperature extremes;

- limited resistance to open flame;

- resistance to fading (ultraviolet radiation);

- long shelf life.

Among the shortcomings, it should be noted:

- long drying period - 48-72 hours. With appropriate supplements, it can be reduced to 36 hours;

- a sharp unpleasant odor that disappears for a long time.

Designed for processing parquet or solid wood flooring, can be used on heated floors

Important! When urethane resins are added to the composition, its wear resistance significantly increases, and the drying time is reduced to 6-12 hours. At the same time, the price increases slightly.

Alkyd-carbamide

Two-component compositions, in which, in addition to the resins of the alkyd group, amino-formaldehyde resins are added. Curing occurs only after the introduction of acidic substances at the kneading stage. The shelf life, depending on the percentage of acids, ranges from a couple of hours to several days.

Two-component varnishes are quite difficult to apply and are usually used by professionals

PHOTO: avatars.mds.yandex.net

It is mainly used indoors for flooring with medium traffic, furniture, etc.

Advantages:

- excellent performance parameters;

- dries quickly.

Disadvantages:

- difficulty in preparation and application;

- limited time of use.

Nitrocellulose

Differs in a wide variety of compositions. It is based on cellulose nitrate, to which plasticizers and synthetic resins are added in various proportions. Forms semi-matt and all types of glossy surfaces. The main area of use is furniture, decorative items and interior decoration made of wood. The nitro lacquer sinks deep into the solid wood, significantly strengthening the outer layers, but it does not resist abrasion well and is not recommended for flooring.

The decorative properties of nitro varnish allow you to refine even ordinary wood species, giving them the appearance of exotic

PHOTO: 1poderevu.ru

Advantages:

- dries quickly: from 30 minutes to 4 hours, depending on the type and amount of solvent;

- well polished with both natural and synthetic agents;

- high decorative performance.

Disadvantages:

- when dry, it emits an unpleasant odor, volatile fire hazardous and toxic fumes;

- provides a coating with medium mechanical strength;

- mediocre protection against moisture and ultraviolet radiation.

Polyurethane

One of the most popular protective and decorative varnishes. It is characterized by high strength parameters and resistance to any external influences, including constant high humidity and aggressive detergents. Designed for indoor and outdoor use. Recommended for protecting surfaces exposed to excessive stress.

Polyurethane resins reliably protect wood even in contact with aggressive sea water

PHOTO: yachtrus.ru

Important! One of the highest quality and most effective protective compounds based on polyurethane was named "yacht", which without further ado describes its capabilities and scope.

Benefits:

- high adhesion to any type of wood;

- protective layer of increased hardness;

- protects painted wood from fading;

- dries up in 4-12 hours.

Disadvantages:

- high price;

- the need for strict adherence to the application technology - to avoid any contact of the base surface with moisture.

Acrylic (water based)

It is one of the safest. During application and further operation, it does not emit unpleasant odors. Recommended for use in hospitals and childcare facilities. Before use, it is recommended to coat the wooden base with an acrylic primer to increase adhesion. Emphasizes the natural texture of the wood.

Creates a protective layer with mediocre abrasion and moisture resistance. Therefore, it is recommended to purchase formulations with additives that increase the strength characteristics. Dries up to 2 weeks. Organic solvents added to the main composition (no more than 15% by volume) accelerate the drying process.

Polyurethane (water based)

It is produced in the form of one or two-component mixtures. Combines high performance parameters with environmental safety. Differs in good elasticity (does not crack) and resistance to aggressive cleaning agents. The only drawback is the high cost.

Epoxy

A two-component compound that forms a protective layer as a result of a chemical reaction under the influence of a hardener. The decorative protective film is hard, durable and shock-resistant. The varnish is intended for interior and exterior use. Dries up to 10 hours.

Epoxy for wood creates a perfectly smooth surface with high reflective properties

PHOTO: kraskistroi.ru

Polyester

In addition to a mixture of polyester resins, the composition contains numerous additives and modifiers. The varnish forms a thick protective layer with excellent decorative qualities. It is used for finishing furniture, floor coverings, decorative elements and musical instruments. It is applied with a special spray.

Alcohol (polish)

Contains ethyl alcohol and natural or synthetic resins. Dries very quickly (15-20 minutes). Creates a decorative rather than a protective layer. It is characterized by low resistance to mechanical stress and high humidity. It is used in furniture making, for finishing decorative items and musical instruments.

The alcohol composition forms a decorative surface with mediocre protective characteristics.

PHOTO: images.ua.prom

How to choose wood varnish

When choosing a composition, not only the wood species is taken into account. It is necessary to determine in what conditions the product or structure will be used. Selection errors can damage the structure and disfigure the surface rather than protect it.

- Appointment. Manufacturers assume a certain area of use for varnishes:

- parquet - high wear resistance of the surface;

- boat (yacht) - resistance to moisture, aggressive environment, temperature changes in a wide range;

- furniture - low strength, but high aesthetic values;

- finishing - for decorative finishing of structures inside the premises. It has high aesthetic properties, affordable cost, and fairly high strength.

- Gloss level. According to this parameter, it is customary to divide any paint and varnish products into 5 main categories:

- high glossy;

- glossy;

- semi-glossy;

- matte;

- semi-matt.

- Drying time. As a rule, this parameter does not affect the quality of the decorative and protective coating. It becomes key when the repair time is limited or it is necessary to cover the surface in three or more layers. Depending on the brand, this can take anywhere from 20 minutes to a week.

- Toxicity. It is about the release of strong smelling and toxic substances during application. Throughout the entire period of operation, all varnishes, without exception, are harmless. The toxicity level depends on the type of solvent. For indoor use, it is recommended to use organic or water-based formulations.

- Number of components:

- One-component - decorative and protective layer is formed by solvent evaporation. Recommended for independent, household use.

- Two-component - the protective film is formed as a result of the reaction between the hardener and the solvent. These are professional formulations that require certain experience in use.

- Heat resistance. This factor should be taken into account if it is planned to process wood in rooms with a high risk of fire or constant sharp changes in temperature.

- Application area. The first thing that buyers pay attention to before buying a varnish is its scope:

- For outdoor work - more elastic, withstands thermal deformation of wood.

- For interior work - harder and more durable.

Major manufacturers of quality wood varnishes

The rating was compiled on the basis of a study of paint sales of leading construction online stores:

- Tikkurila (Finland). Produces a full range of paints and varnishes. Differs in the highest quality. Has the ability to tint on special equipment;

- Dufa (Germany) - a wide range, reasonable cost, environmental safety;

- Dulux (UK) - our own laboratories develop varnish with unique performance characteristics;

- Marshall (Turkey) - affordable cost is combined with good performance parameters;

- Caparol (Austria) - rather high cost of varnishes is compensated by impeccable decorative and protective properties;

- Beckers (Switzerland) - the products are absolutely safe and environmentally friendly;

- Pinotex (Russia) - specializes in the production of paints and varnishes for wood;

- Sayerlack (Italy) - a wide range of pigmented varnishes for solid wood furniture, more than 3500 items;

- Berger (Germany) - specializes in parquet varnishes, including for public places with high traffic;

- Vermeister (Italy) - produces high quality universal water-based polyurethane varnishes.

The range and specialization of Caparol products makes them so popular in the domestic market

PHOTO: oxidom.com

Popular brands of varnishes and reviews on them

Now let's study customer reviews about different brands of varnish for wood.

Review of Tikkurila Euro kiri parquet varnish:

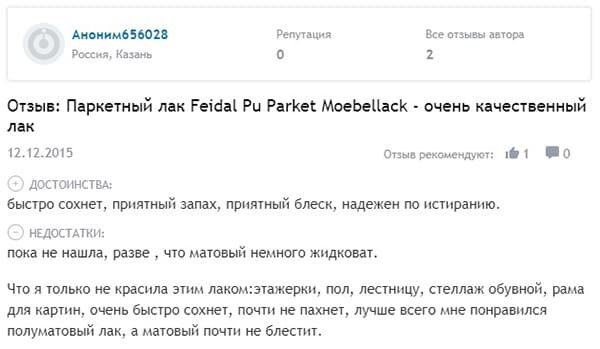

Review of Feidal Pu Parket Moebellack parquet varnish:

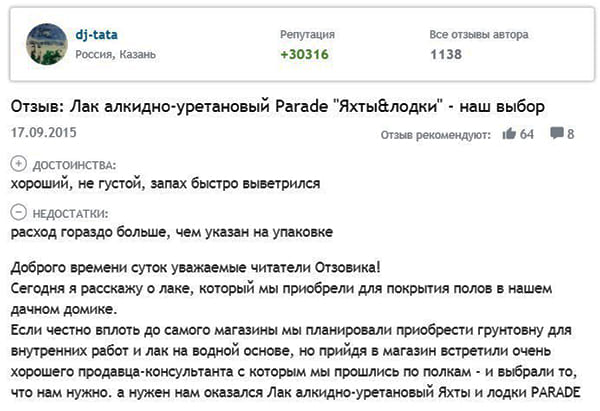

Review of alkyd-urethane varnish Parade "Yachts & Boats":

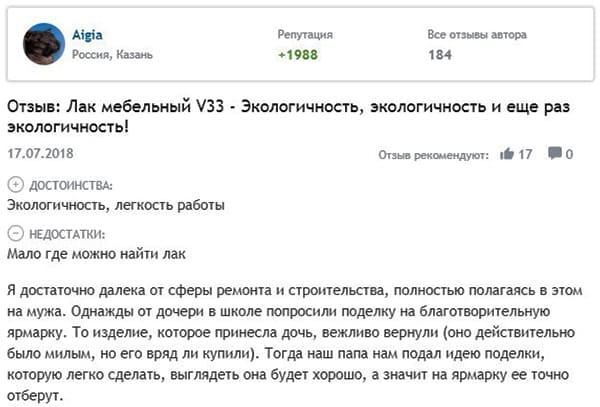

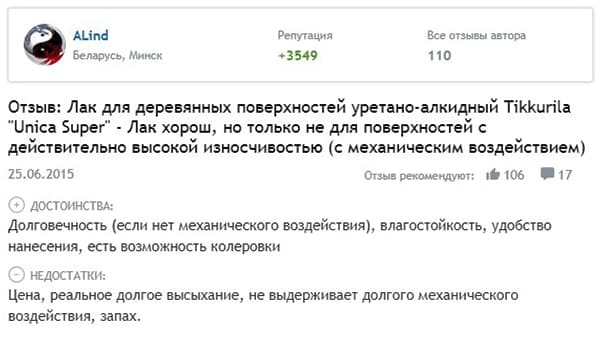

Review of Tikkurila "Unica Super" urethane-alkyd varnish for wooden surfaces:

Review of Tikkurila Taika Glow matte varnish with glow effect:

Gallery of products treated with decorative varnishes:

- PHOTO: berkem.ru

- PHOTO: parket03.ru

- PHOTO: i.ytimg.com

- PHOTO: mmvikont.ru

Application methods

Like other paintwork materials, varnishes, depending on their viscosity, can be applied with a brush, roller or spray. Before starting work, the surface of the base is thoroughly cleaned and polished. Many compounds, especially two-component epoxy and polyurethane, are very sensitive to high humidity at the time of application. Therefore, water must be avoided on the work surface.

Some paints and varnishes require preliminary coating with primer or special primer varnishes. It is highly recommended to use primer from the same manufacturer. Water-soluble varnishes can be used as a primer, after being diluted with water within 10-25% of the total volume. Using a special primer can significantly reduce the consumption of more expensive finishing mixtures.

Applying varnish with a spatula is a rather complicated procedure, which is best left to professionals.

PHOTO: chudopol.ru

There is a specific way of applying viscous varnishes - a spatula. Its use can reduce consumption by several times and form a perfectly smooth surface without lint and traces of smears.

conclusions

The use of varnishes will not only protect wood products, but also give them a more aesthetic appearance. However, a wide range of specialized paintwork materials can play a cruel joke, and choosing the wrong composition will ruin the product. Therefore, if in doubt, it is strongly recommended to consult a specialist.

If you liked the article, share the link with your friends. We will be glad if you take part in its discussion.