What is the best substrate for the laminate: why is it needed, and what criteria should be considered when buying

Any person who buys an apartment or makes repairs in it faces the question of purchasing flooring. There are many options for laying the floor, one of the most popular is laminate. This material is considered durable and inexpensive. In order to properly lay it, you should follow all the stages, including the preparatory ones. It is at this stage of the work that the question arises, which substrate is better for the laminate.

The content of the article

Why do I need a laminate gasket

The use of the substrate is based on the characteristics of the material of the floor covering. It is made from waste wood processing enterprises. That is, sawdust is pressed under the influence of high pressure and temperature.

On the finished sheets, a decorative layer is applied from above, repeating the texture of the wood. Then, the entire surface is varnished to increase the service life. On the underside of the laminate boards there is a layer of polymers that protects the material from moisture and mechanical damage.

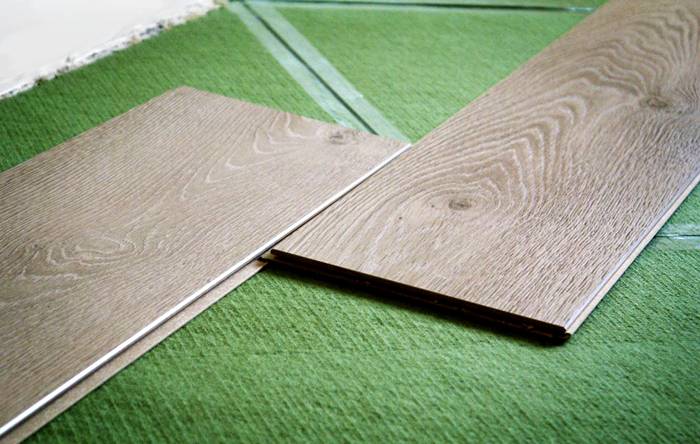

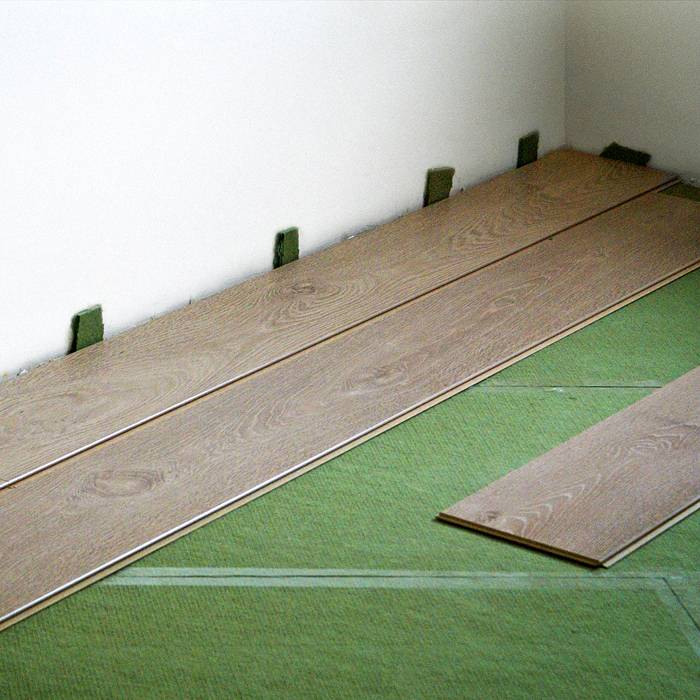

Locks for fastening are installed on all sides of the resulting panel, so it is not difficult to lay the laminate. Planks are laid on the screed.

Note! When laying laminate boards the difference in unevenness on the floor should not be more than 1 mm per 2 running meters.

In this case, you cannot lay the boards directly on concrete, otherwise, when walking, they will knock on the screed and quickly wear out.. It is for these purposes that the lining was developed, which acts as a shock absorber, and also increases the level of sound insulation in the room. And it also provides the necessary level of vapor barrier so that the coating does not deform during operation.

Which substrate for the laminate is better based on its characteristics

There are different options for laying between the floor and the covering:

- from cork;

- polymers;

- foil;

- needles;

- combined options.

To choose a substrate for a laminate on a concrete floor, it is necessary to take into account the characteristics of each of the listed types.

Cork covering

The main advantage is environmental friendliness. Even in the children's room, you can safely use a cork lining, it does not emit any harmful substances. And also this material has a long service life, good shock absorption and sound insulation.

Besides the positive aspects, there are also negative ones. These include:

- high price;

- afraid of moisture, therefore it is not used for warm floors.

It is made from oak bark chips. Sometimes they use not only natural material, but also add rubber or bitumen, which reduces the cost.

Thus, it is advisable to use such a coating for dry rooms, without installing underfloor heating. Most often, cork is combined with an inexpensive laminate to optimize the overall cost of the flooring.

Foam backing

Laminate substrates (sheet) are made of polyethylene foam in several versions. They all have positive aspects, which include:

- High ability to keep moisture out;

- Keeps warm well;

- Not affected by bacteria and various chemicals;

- Light weight and low cost.

However, there is a drawback that outweighs all of this - a short service life and a quick loss of shape. That is, such a substrate will be acceptable in a room with high humidity and on a floor made of boards, which itself requires periodic repairs.

Expanded polystyrene

The material is recognized as the golden mean in terms of price and quality. This option consists of two layers: expanded polystyrene and foil. There are also extruded (single-layer).

The underlay is easy to install, does not transmit sound and heat, hides various floor defects, and at a price it is an affordable option for many consumers. There is only one drawback - during long-term operation it can lose its shape.

If you choose a substrate for a laminate on a warm floor, which is better suited for such a coating, then expanded polystyrene is a suitable material for such structures.

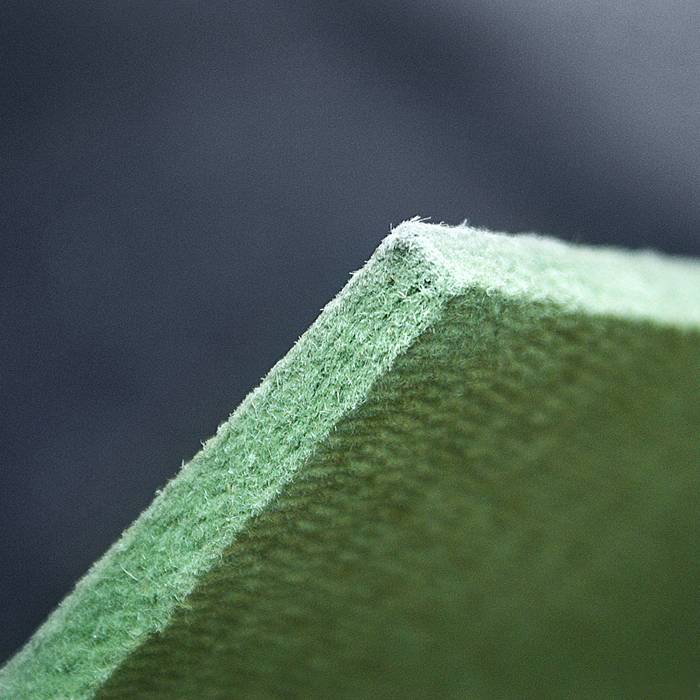

From wood

This option is made from natural materials, is able to "breathe", but the price is much higher. Despite the cost, sheets from woodworking industry waste are in great demand, due to their durability and thermal insulation qualities, by which they are compared with soft insulation.

For example, a coniferous substrate for a laminate has the following customer reviews: “I don't write reviews often, but this backing amazed me. It has been with me for more than three years, during which time it has not caused any allergies or any other troubles. I thought that the coating would start to "walk", but nothing like that happened. Very satisfied".

Another review: “One friend made a bed for himself, was unpleasantly surprised by the scent from it. I could not stand it, I handed it over to the store, as it turned out, the needles perfectly absorb all the smells. We replaced it with a new package, everything was already in order with it. "

Thus, it is rather difficult to accurately answer the question of which substrate for a laminate is better. For each buyer, the right option will be good, based on the purpose of use, humidity in the room and the planned cost of money.

Which substrate for laminate (price per m2) will be more profitable

When deciding which option from the whole variety is more suitable, we suggest looking at the table with indicative prices.

And also when choosing, you can look at the rating of manufacturers, according to buyers:

- The best natural substrates. In the first place is Premium Cork (Portugal), this material has a high density and low thermal conductivity... Made from pressed bark of balsa tree. Price: 90 rub. per sq. meter (2mm). Next comes PARCOLAG (bitumen-cork version). Refers to ventilated material. Price: 95 rubles with a thickness of 3 mm.

- From extruded polystyrene, buyers selected VTM, IsoPolin. This gasket is considered the best in terms of price and quality. It has high performance in noise and heat insulation. Price: 55 rub. per square meter.

- Among the polyethylene options, consumers singled out Tuplex, worth 99 rubles. The substrate is made of modern materials that allow ventilation of the space.

Thus, when you think about which substrate for the laminate is better to choose, you can rely not only on the material of manufacture, but also on the user rating, as well as on the pricing policy.

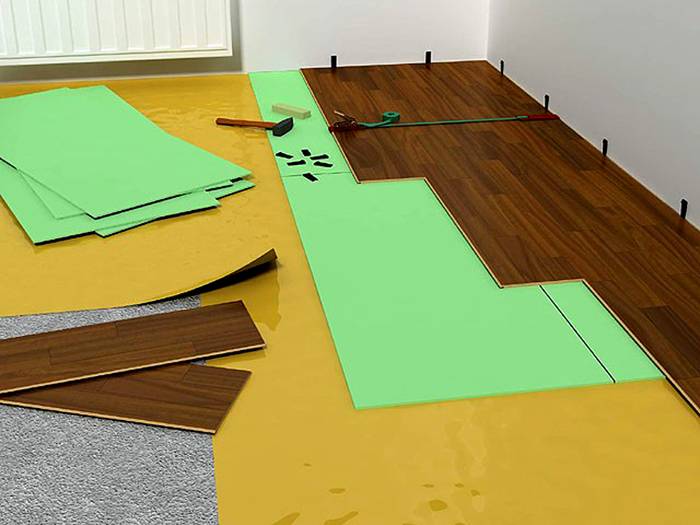

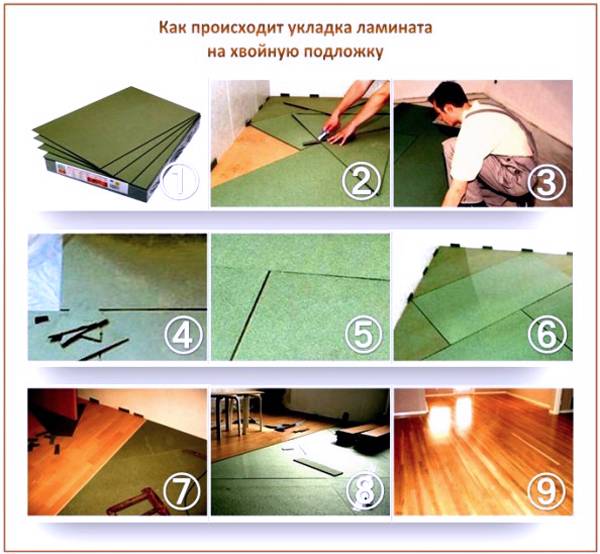

Styling tips

There are several recommendations based on the choice of substrate material:

- If you are using the natural option, be sure to lay the film on the black-eyed finish (200 microns). This is necessary for complete isolation from moisture and protection from the appearance of fungus.

- The artificial substrate can be laid directly on a rough, leveled floor, the moisture level of which should be checked and, if necessary, treated with special means.

Note! The joints in the backing and laminate must not match.

Soft coverings, which are folded in rolls or sheets, are most often laid with overlapping walls. But the height should not exceed 5 mm. This option is not suitable for a rigid substrate such as Isoplat.

To make it easier for you to make your choice, we suggest watching a video on the pros and cons of various materials, as well as how to properly lay the substrate.

Video: how to properly lay the substrate under the laminate