Choosing tips for crimping wires: product types and crimping rules

To connect a household appliance to the electrical network, it is necessary not only to correctly connect the cable, but also to ensure its snug fit and reliable contact. To make a strong connection, crimp cable lugs are used. To complete the procedure, certain rules and the presence of a special tool are required. In today's review, we will analyze what tips exist and how they are correctly crimped.

The content of the article

- 1 What are crimped cable lugs for and applications

- 2 Marking

- 3 Execution options

- 4 Correct selection of tips for crimping

- 5 The main types of tips for crimping

- 6 Basic rules for crimping

- 7 Pin tips NSHVI

- 8 The nuances of working with NShVI

- 9 At what price can I buy terminals for crimping wires

- 10 Video: crimping / crimping wires with various ferrules and electrical tools

What are crimped cable lugs for and applications

The use of cable lugs significantly increases the quality of the electrician's work and also facilitates the procedure cable connections... With the help of lugs and sleeves, the cables are terminated for their firm fixation. Using aluminum, copper and combination lugs, it is possible to combine power sources and different installations.

The tips are versatile. In the modern market, a huge assortment of them is offered, from which you can choose the necessary option for a certain type of installation work.

In order to be able to select the tip for a certain section, it is marked during production. If the dimensions are selected correctly, the crimping of the cable ends will be as reliable as possible.

Marking

The industry produces a large number of all kinds of handpieces that differ in design and materials.

There is a special marking system that allows you to distinguish the material and use it for its intended purpose. Here are some notations in this system:

- A - the sleeve is made of aluminum;

- L - brass is used;

- M - copper is the basis of the product;

- T - the element is made of tubular metal;

- U - the connector is made in the form of an angle.

There is also a designation in the form of the letter O, which indicates the presence of a viewing window through which you can make sure that the cables are correctly positioned in the bushing inside.

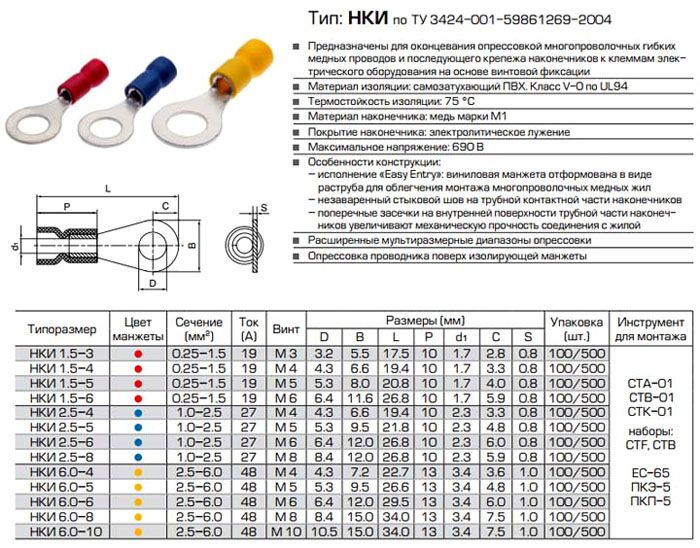

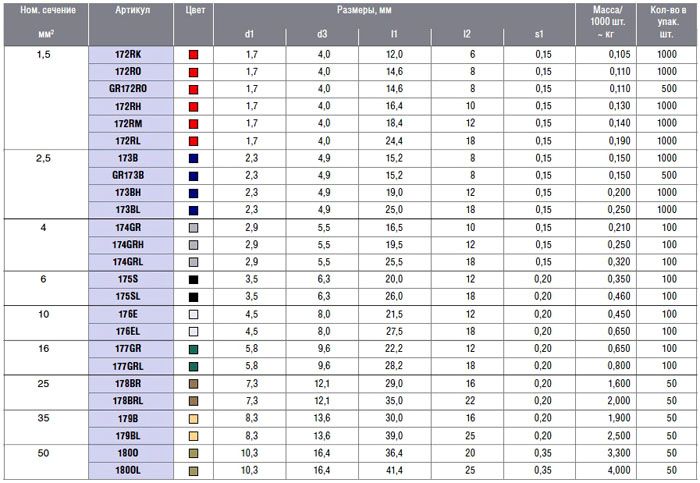

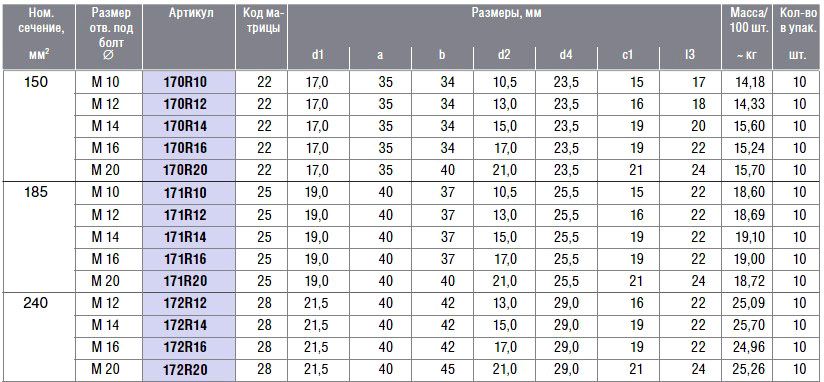

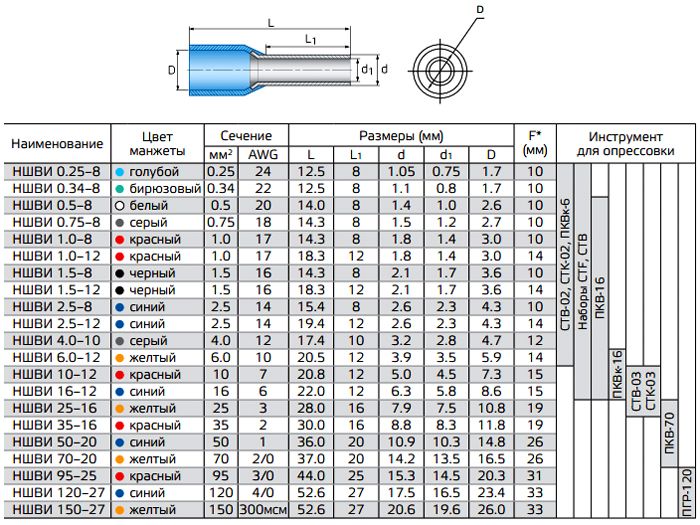

If the marking is TML (O), then it denotes tinned tubular copper with a window for inspection. NSHVI - denotes a pin sleeve tip, and NCI - annular. In this case, the numbers indicate the cross-sectional area or diameters of the bar. To facilitate the search for suitable connectors, for example, NSHVI or KBT, you can use a special catalog or tables.

Execution options

By design features, the tips are single and double. The product is an electroplated copper tube. The ferrule can be flared at one end. This is necessary when working with stranded wire. The insulating component is a polyamide cuff.

Note! Useful elements protect homes from fire or heating of the wiring due to poor fixing of the wires.

Correct selection of tips for crimping

Before starting work on crimping, it is necessary to choose the right tip. These products can have different liner thicknesses or different inlet diameters. To achieve a good connection, it is important that the stripped cable matches the diameter of the tail of the lug.

If the tip is aluminum, then the product must be selected with the same cross-section as that of the wire. If the material is copper, then you can face certain difficulties.

The following solutions are possible here:

- the desired option can be selected using tables from GOST. In this case, you will need knowledge about the flexibility classes of the conductors;

- you can measure the diameter with a vernier caliper. Then compare it with the cross-section of the inside with a caliper.

The material of the ferrules and sleeves must match the material of the core or wire. Otherwise, corrosive processes will occur.

Note! The core diameter should be slightly smaller, but not larger than the shank diameter.

The main types of tips for crimping

There are different types of ferrules for use with wires of different modifications and cross-sections. Let's consider the most popular ones:

- copper lugs. Used to work with copper wires. They are made from seamless tubes. On one side there is a clamping part, and on the other side there is a tubular hole for the wire. Lugs of this type are used to install electrical appliances, connect input-distribution devices and for grounding;

- aluminum. For aluminum conductors, lugs of the same material are used. At one end there is a contact vane with a hole, and the other is a tubular hole. The cores are connected to the ferrule by pressing with a special tool. The product is preliminarily lubricated with quartz-vaseline grease, which protects against oxidation;

- aluminum-copper. Copper busbars can be used in switchgears, for which aluminum-copper lugs are suitable. In them, the landing tube is made of aluminum, and the contact blade is made of copper. Products are made by frictional diffusion or by gas-dynamic spraying. In this case, copper spraying covers the product from above, which allows for a stable contact;

- bolted. These lugs are attached with a clamping bolt.In this case, crimping is not necessary as the bolt is part of the tip. Tightening is done with a wrench.

Basic rules for crimping

To perform high-quality crimping of wires with sleeves or lugs, the following rules must be observed:

- choose the right tip;

- correctly and thoroughly strip the vein;

- use specialized tools for work;

- choose a suitable matrix;

- observe the crimping sequence.

It is important to correctly set the diameter of the hole on the tool so as not to damage the connected elements.

You can see the features of crimping in this video:

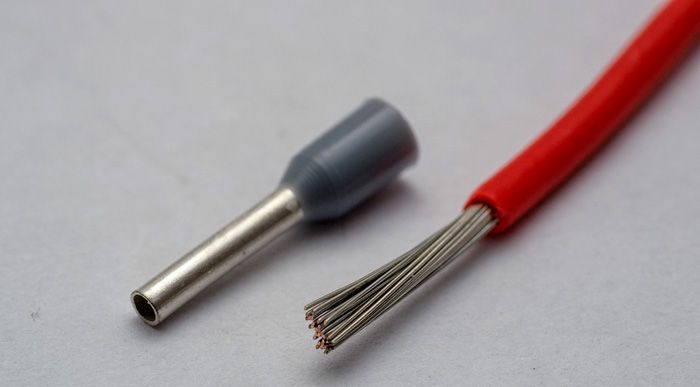

Pin tips NSHVI

NSHVI are pin bushings for crimped wires. They are made of electrolytic copper with insulation on the back. The material is processed by galvanic tinning. In everyday life and industrial purposes, such lugs are used for cables with a cross section of 0.25 sq. mm. NShVI has many advantages and one of them is time saving when connecting to electrical devices.

Products are single and double. When used, it takes only a few seconds to install the cable. The pin tip does not require any special skills to use. There are NSHVI tips with different sleeve sizes. In this case, color coding is applied.

The nuances of working with NShVI

If a multicore cable is used, it is recommended to buy an NSHVI lug. This type is not used for terminating a single conductor wire.

Crimping a multicore cable is performed as follows:

- it is necessary to select the wire cross-section and the type of the tip. The veins should enter freely from the side of the skirt;

- tip type should be selected with some margin. A wire with a cross section of 1.25 mm is crimped with a lug from 1.5 sq. mm, and the section of the skirt is up to 2.5 sq. mm.

Required tools

Crimping is carried out with a special tool that allows you to create the required force. The following tools are popular:

- press pliers for crimping the ferrules PK2 and PK2M are used for terminating conductors with a cross section of up to 10 sq. mm;

- the tool of the PK1 and PK1M brands is a more powerful version of hand pliers;

- hydraulic pliers allow crimping wires up to 10 sq. mm;

- in industrial production, a hand press is used. It is suitable for wires up to 240 sq. mm;

- the hydraulic press with electric drive is applicable for cables up to 300 sq. mm.

Pressing jaws with hinges increase the pressure of the tool, which makes the process easier manual crimping... The ratchet mechanisms are especially convenient. They prevent the instrument from being released before the procedure is complete.

How to crimp a wire without tools can be seen in this video:

Sleeves for wires for crimping

Not all devices or devices use cable lugs - there is also a sleeve termination. For cables with copper conductors, sleeves with the GML marking are used, which means tinned copper sleeve. For wires made of aluminum, the GAO brand is suitable. This is a closed-type sleeve made of aluminum. If it is required to make a connection with a connection of the elements of copper and aluminum, then an alloy is used.

Preparation for crimping

Before you put the tip on the core, you need to do some preparation:

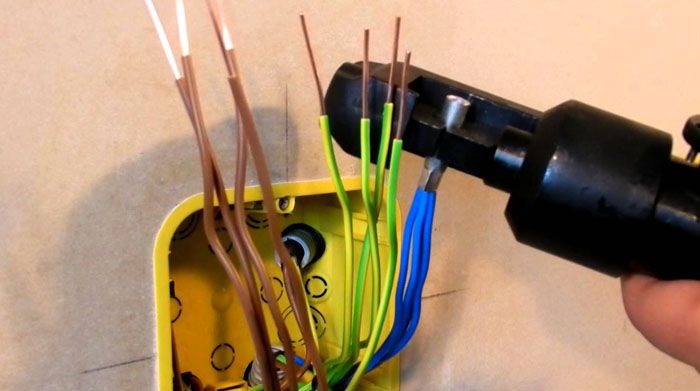

- clean the required gap of the wire from insulation. For this, you can use a special tool;

- Twist the cores by hand and place them in the tip from the side of the skirt.

It is important to select the correct conductor cross-section to ensure easy entry into the lug sleeve.

How to crimp a wire

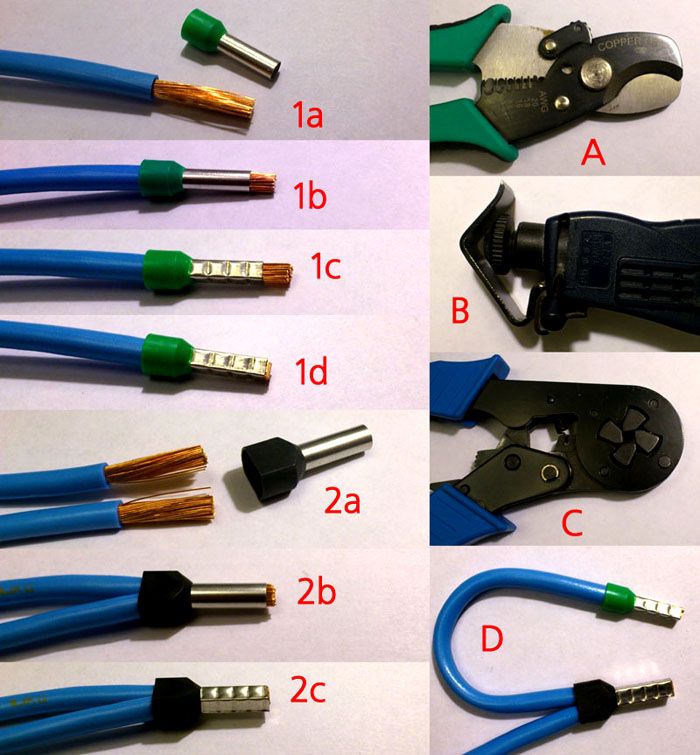

After selecting the correct lugs and wires, you will need a special tool.Crimping pliers resemble pliers, at the end of which there is a special matrix where the lugs and an uninsulated section of the cable are installed. This device allows you to apply pressure to the tip evenly from all sides. Particular attention should be paid to the type of cable, which can be multi-core or with a solid core.

Single ferrule crimp

To make a high-quality crimp, it is recommended to observe the following recommendations:

- so that the conductors do not fall out of the socket, the conductor should be fixed when placing the tool in the matrix;

- crimping is performed with pliers until the snoring mechanism is connected, which allows blocking the tool from unclamping;

- if the fixation is carried out manually, then the control is carried out by stretching the hand. If the crimp is of high quality, then the installation will be tight without movement;

- you can use a double-line crimp tool. Termination is carried out by squeezing the insulator and the sleeve in sockets with different diameters;

- in conclusion, you need to check the strength of the contact, slightly tightening the elements.

Note! When performing crimping for the first time, it is worth practicing on an unnecessary piece of wire. It is better to ruin one tip than the entire wire.

Double Tip Crimp

The connection of two conductors to a phase is carried out on one contact. When installing modular machines, they are connected using special jumpers. One contact has a pair of cables.

In this case, it is recommended to use NSHVI for two wires. Here are some of the mounting features:

- two wires are installed inside the cuff at once;

- it is better to crimp with press tongs. When pressing a double tip, it is better to use a die with a cross section of 6 sq. mm.

Crimping power cable lugs

For crimping the power cable, it is recommended to use a tinned copper ferrule that is protected against oxidation. When you cut the cable, the edge may fluff up and become larger than the rest of the core. In this case, the edge can be removed with a sharpener. The cable should be unrolled so that the circle removes excess along the veins, but does not bend them.

It is not necessary to use the soldering method for crimping, since a contact made only with pure tin cannot be used on the wires.

Note! In order not to be mistaken with the size of the tip, you should go to the store with the cable and select the required size on the spot.

At what price can I buy terminals for crimping wires

Before heading to the store, you should familiarize yourself with the options on the market in advance. The table shows the prices for some crimp terminals.

To choose a quality product, remember that a specific wire must correspond to each tip.The mismatch of these two elements most often leads to errors when performing crimping. Do not use homemade tips or cut the sleeve in two to save money. We hope you find our tips useful and help you make the right choice.

Video: crimping / crimping wires with various ferrules and electrical tools