Plastic caisson for a well - a modern solution for providing a house with water

To autonomous residential water supply worked without interruption throughout the years, it is necessary to protect the source from the negative effects of the natural environment. The optimal solution is a plastic caisson. For the well, it will be not only a protection against freezing, but also a barrier against the ingress of groundwater.

The content of the article

Why plastic containers are preferred

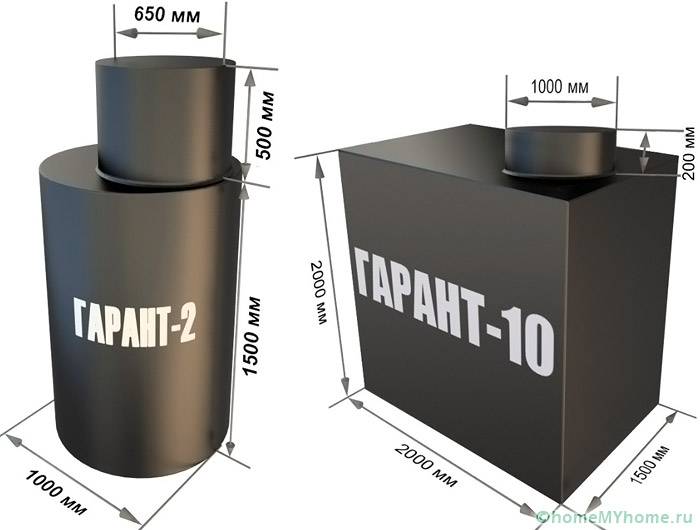

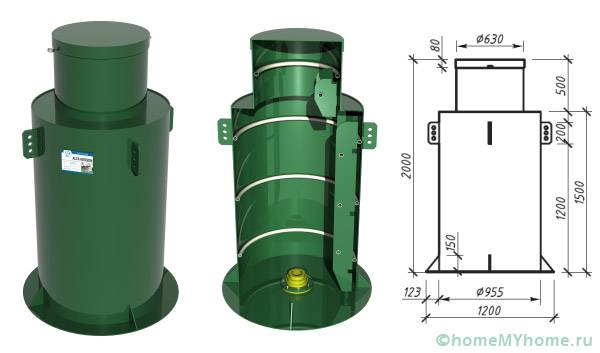

The plastic chamber is a capacious cylinder-shaped tank. Its diameter can vary between 100-150 cm. As for the height, it can reach 2.5 m. There are other standard sizes and shapes of containers, but they are less popular in individual construction.

Of the advantages of plastic products, it should be noted:

- light weight, facilitating the process of transportation and installation;

- tightness to protect the interior from groundwater penetration;

- absence of corrosive processes;

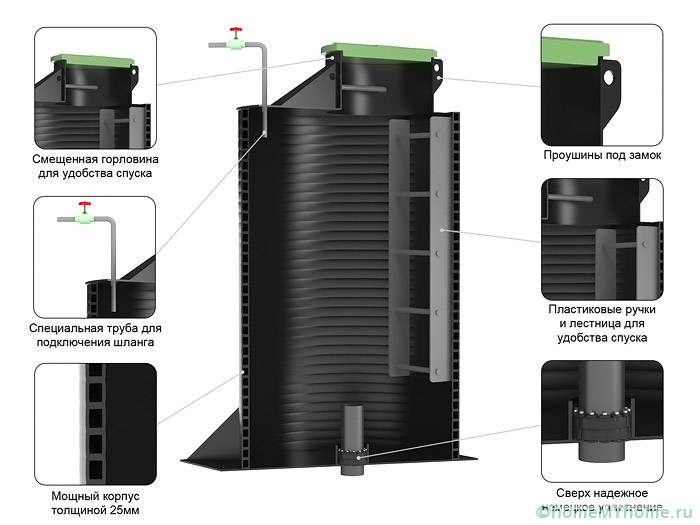

- strength that can be achieved due to stiffening ribs;

- ease of use.

Addition! Anchoring eyes or a lower skirt prevent the plastic container from floating in the event of a significant rise in groundwater.

Concrete and plastic well caisson: comparison of construction processes

To make sure of the simplicity of the construction of the plastic caisson, it is proposed to compare the process of its construction with the construction of a structure made of concrete rings. The difference will be quite obvious. However, it is better to choose concrete to create increased strength chambers.

Installation of plastic caissons for a well

Tanks for placement in the ground are made of polypropylene sheet, which belongs to the category of fairly light materials. Unlike the same concrete rings, it is much easier to lower plastic containers into the pit. After placement in the pit, no additional work is required to fill the floor and seal the joints.

The installation scheme of the plastic caisson is as follows.

- Pit preparation is carried out directly around the casing. Its dimensions should be approximately 20-30 cm higher than the linear parameters of the container itself.

- The bottom of the pit is covered with a layer of sand to level the surface. The bottom of the plastic container should be in a horizontal position. In addition, the sand layer allows for a more reliable base.

- The casing pipe is cut to length, after which a plastic container is lowered into the pit. The main hole is sealed. A cover is installed on top.

- The rest of the pit is filled with a mixture of sand and cement in a ratio of 5 to 1.

Note! If the groundwater is very close, then first a concrete slab is placed in the pit, and a plastic container is already attached to it. This will prevent the structure from floating outward.

Related article:

A septic tank for a summer residence with a high GWL. A separate material provides information on arrangement of septic tanks with high ground water level, installation and operating rules.

Reliable caisson made of concrete rings for a well with your own hands: a description of the construction process

It is worth resorting to the construction of a concrete caisson if special requirements are imposed on the structure in terms of strength. For the construction, you will need to purchase two ready-made rings of concrete products. Usually this height is sufficient for the construction of the auxiliary chamber for the well.

For the rings, a pit is prepared according to the same principle. After that, the elements are stacked on top of each other. The top ring should protrude 10-15 cm from the ground. After installing the base, the bottom is poured with a concrete composition. Seams between concrete rings are covered with a cement-sand mixture. From above, the structure is covered with a special cover made of the same concrete. A hatch is installed on it for penetration into the interior.

The main advantages of concrete caissons include:

- high strength;

- uncomplicated device technology;

- long operational period;

- high speed of construction;

- the possibility of deepening is not limited.

As for the disadvantages, they are as follows:

- the impressive weight of the rings complicates transportation and installation work;

- to achieve tightness, additional measures should be taken related to sealing joints;

- to increase the service life, waterproofing operations are required.

Note! Ordinary foam can be used as additional thermal insulation. The material can be fixed to the side surfaces with an adhesive.

Well caissons prices: ready-made plastic containers

The easiest way is to buy a plastic caisson for a well and dig it into the ground yourself. Depending on the dimensions, the cost of finished products may vary somewhat. The table shows the sizes with the prices of manufacturers who produce reliable products.

Table 1. Average cost of caissons for a well.

| Picture | Model | Dimensions in millimeters | Price in rubles |

|---|---|---|---|

| Titan-P | 2000x960 | 27 500 |

| 1200x2000 | 32 500 | ||

| 1500x2500 | 58 000 | ||

| Bio-C | 1500x960 | 25 000 |

| 2000x960 | 30 000 | ||

| 1200x2000 | 35 000 |

Note! Since the cost of installing a caisson per well is relatively high, it is best to carry out the work on digging in the tank without involving firms in order to save money.

About the main materials of manufacture

Ready-made containers are mainly made from two types of plastic - polypropylene or cross-linked polyethylene. In general, their characteristics are very similar, but there are still differences.

Polyethylene is made by cross-linking at the level of linear ethylene macromolecules, until a three-dimensional mesh-like structure is formed. During the process, stable bonds between molecules are created, so the material is sufficiently strong and resistant to chemical attack.

Polypropylene has an unstable crystal structure, which results in a high level of plasticity. In terms of density, it is somewhat inferior to cross-linked polyethylene.

Both materials can be used over a wide temperature range. They make plastic caissons for wells that can serve for a long time in the harshest conditions. However, the melting point of polyethylene is about 25 degrees higher.

To increase the operational period in the production of polypropylene and polyethylene products, stabilizers are added to improve resistance to natural factors.

Due to its elasticity, polypropylene is not susceptible to cracking. Even under unfavorable conditions, it retains its structure. Polyethylene shows itself well with a sharp increase in loads. Increasing the tensile speed of polypropylene leads to a decrease in mechanical resistance.

Summarizing

In most cases, a plastic well caisson is the optimal solution. With proper installation and operation, containers can serve for at least 50 years. As for analogs made of concrete rings, it is recommended to arrange them in special situations when significant loads are placed on the structure from the outside.

Video: Alta Kesson plastic caisson and its installation