Diy well without equipment: the principle of the device

A budget option for making an autonomous source of water supply is a well with your own hands without equipment using several existing technologies. This refers to ways to do without renting a drilling rig. However, some equipment and tools are still required by the DIYer.

The content of the article

Video: water well without the aid of a drilling rig

Purpose, device nuances

In comparison with a well, the well has a smaller size, allowing you to save the working space of the site. The mouth of the source is sealed much easier; sediments and dirt do not get inside. There is no need to remove a large amount of soil, take it out of the construction site.

A well is being built with your own hands without equipment in several ways:

- by eroding the soil with water;

- extraction of rock with a hand drill auger;

- or a homemade bailer.

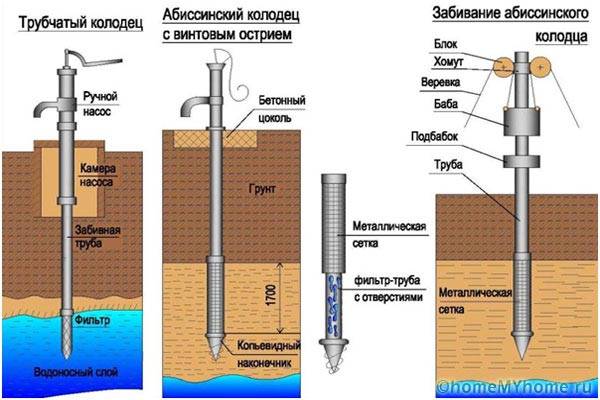

The most economical method is the Abyssinian well, from which no soil is extracted at all. The soil is compacted when the growing pipes are clogged, the column becomes operational, through it water enters the pressure line.

Manufacturing methods, materials, tools

To make a well with your own hands without equipment using the indicated technologies, you will need various tools and materials. Below will be considered the budget, the pros, cons of the designs of water intake sources.

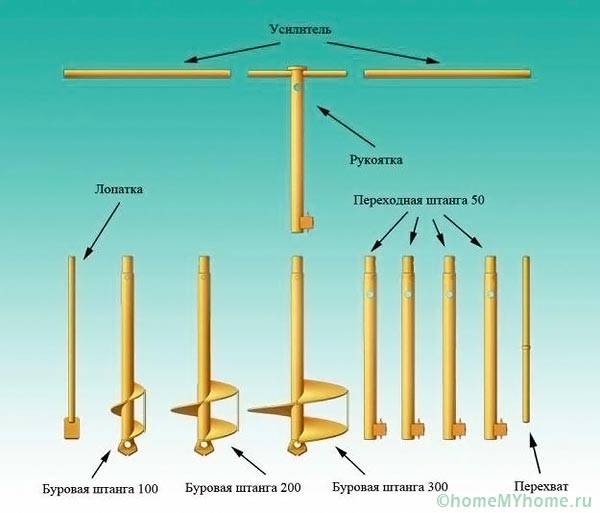

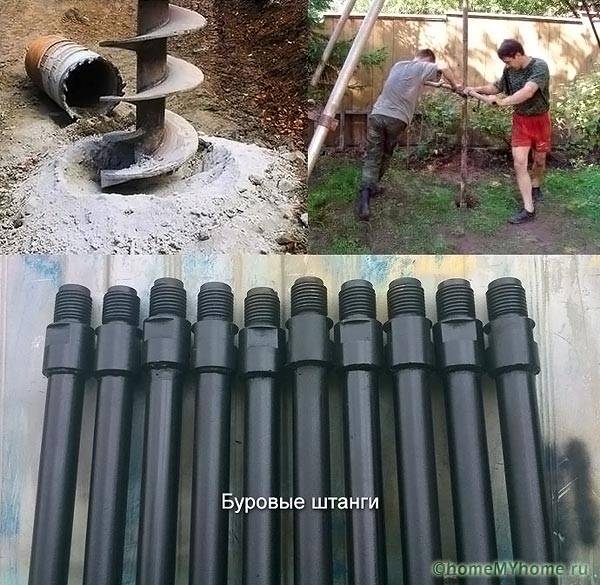

Manual auger

When choosing classic drilling, you will need to purchase hand tools with auger or removable knives. The technology consists of operations:

- drilling - the height of the hand drill does not allow reaching, even the horizons of the upper water, therefore, after deepening by 1 - 1.5 m, the rod is extended by the next section;

- casing - usually made of polyethylene pipes, in the lower part it is perforated with slots or round holes, or a factory, home-made filter is attached to the bottom;

- flushing - usually 2 - 3 buckets of very dirty water are pumped out, then 1 - 2 cubic meters of liquid with sand, after which the quality is normalized;

The advantages of the method:

- low construction budget - purchase of a drill + production of rods with locks for extension;

- penetration rate - the auger is an Archimedes screw, along which the soil moves up independently.

When choosing a drill with replaceable blades, labor costs are dramatically increased. After a few revolutions, the tool must be lifted to shake off the rock. In any case, a home craftsman can do without helpers. The disadvantages of the technology are:

- complex vertical positioning;

- numerous descents / ascents.

The diameter of the tooling of hand-held drills is limited to 40 cm, if you wish, you can find 50 cm augers, which are produced by 3 - 4 manufacturers of the Russian Federation. This dramatically limits the diameter of the casing, allowing low-power submersible pumps to be lowered into it.

Useful advice! As soon as the drill reaches the aquifer, the soil ceases to linger on the auger, blades. Further drilling is carried out by flushing, for which water is supplied to the bottomhole under pressure.

Abyssinian well-needle

There is a method of building a source of water intake without excavation. The hole in the ground is made by compacting the adjacent rocks by driving a small diameter pipe. That is, the working tool after reaching the aquifer simply becomes a casing string.

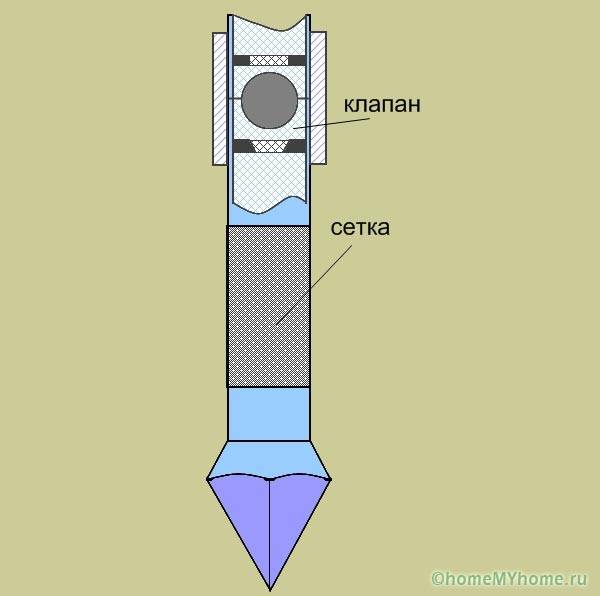

Therefore, all the necessary equipment is mounted on the pipe before driving:

- the cone - slightly larger in diameter than the pipe, so that the compacted soil does not damage the equipment installed above it, is made of steel bar on lathe or blacksmith equipment;

- filter - the pipe is perforated with round holes, wrapped on top with wire or V-shaped mesh;

- check valve - mounted inside the pipe above filter, usually a diaphragm with a heavy bearing ball;

- pipe - 1 - 1.5 m, builds up as the column is immersed with threaded or welded joints.

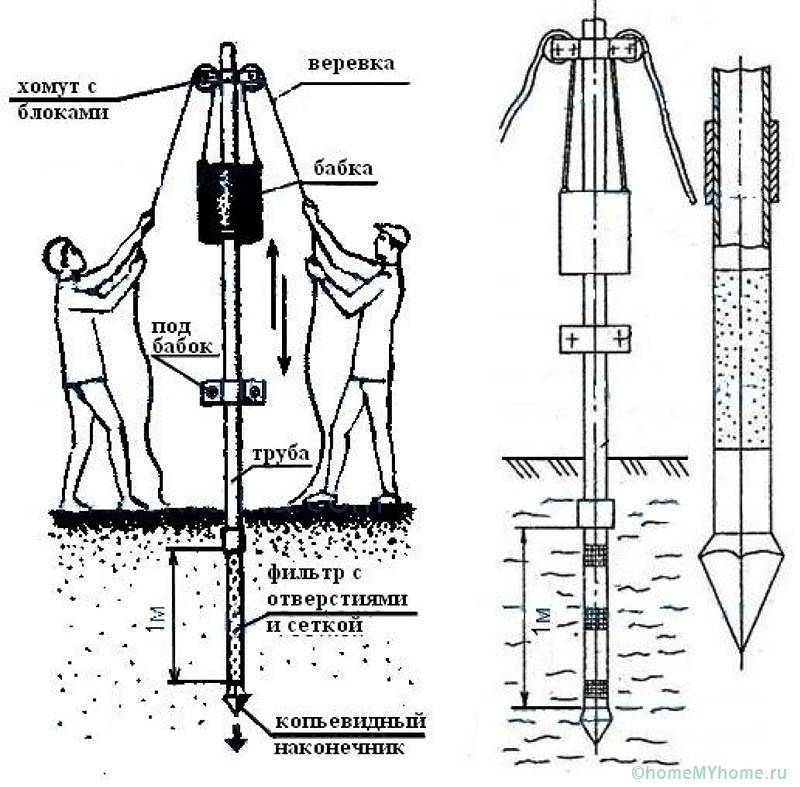

A needle well is made by hand without equipment, but a special tool is needed - a grandmother. An Abyssinian well does not need a tripod, auger, or a flush pump. However, hammering with a sledgehammer flattens the top of the pipe, so a different scheme is used:

- the tool is installed vertically at the mouth;

- 50 - 70 cm from the ground on the body of the pipe is fastened with clamps a platform-podbabok;

- a headstock is put on the pipe (concrete or steel billet with an inner hole to fit the pipe).

- a traveling block is attached to the very top of the pipe with clamps;

- ropes / cables are attached to the headstock, thrown over the pulleys of the block on different sides.

After that, one or two workers simultaneously lift the headstock up to the traveling block, release the cable. The headstock hits the site, the pipe is driven into the ground, the operation is repeated until the site is near the ground. Then the pipe is built up, the chimney and traveling block rise higher.

Despite the low construction budget (5-7 thousand rubles), the technology has some disadvantages:

- difficulties in finding a headstock, a support platform or making these devices with your own hands;

- polymer pipes cannot be used for percussion drilling, steel pipe has a shorter resource.

Useful advice! If necessary, you can fix the podbabok with clamps on the pipe, pull the column out with jacks to clean or replace the filter, check valve.

Bailer drilling

In addition to the listed methods, a well can be made by hand without equipment using the bailer method, which is also called percussion rope drilling.

For this, a sequence of operations is used:

- a tripod - 1.5 - 2 m high, is mounted on the mouth, a traveling block is fixed in the upper part;

- drilling - the bailer is lifted by a cable to the traveling block, released, falls to the ground, filled with rock, after the extraction of the earth, the operation is repeated.

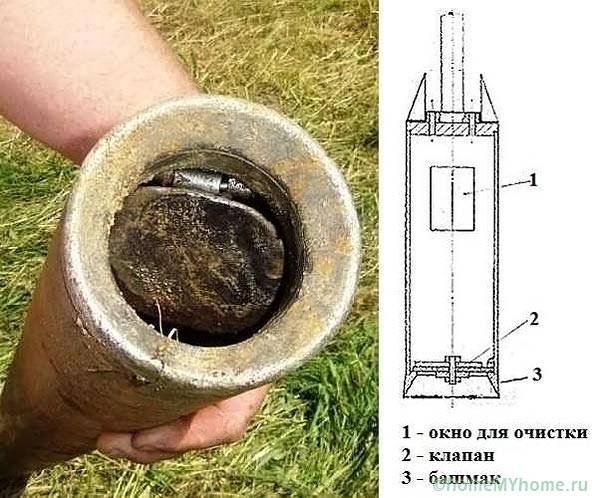

The bailer is made from a pipe, the lower edge of which is sharpened (chamfer) or has teeth for breaking the formation. A round plug is installed inside the hinge to the size of the inner diameter of the pipe. When hitting the ground, the plug opens on a hinge, when removed, it closes under the weight of the soil that has accumulated inside.

On dense soils, after impact, the pipe additionally rotates with levers welded or passed through the holes. This allows you to increase productivity, reduce labor costs.

Useful advice! The main advantage is the ability to extract rock upon reaching the aquifer. The well is obtained deeper, which provides a higher production rate than with manual drilling.

The disadvantage of this technique is the need to purchase a thick-walled pipe with a length of 1 - 1.5 m. Since the effectiveness of drilling depends on the severity of the tool.

Hydrodrilling

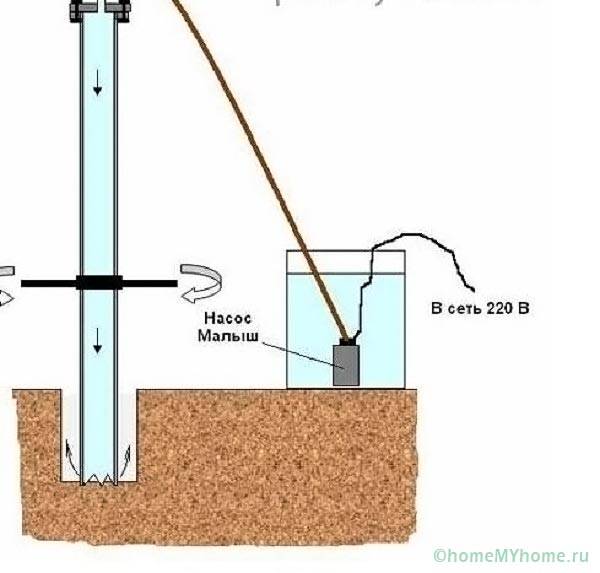

The soil can not only be compacted with a "needle" when driving in the string, removed from the well with a thief, auger, but also destroyed by a pressure jet. However, hydrodrilling technology also uses a thief to form a round hole. Therefore, the technique consists of stages:

- production of a pit - depth 40 - 60 cm, dimensions 0.5 x 0.5 m;

- tank preparation - eurocube, irrigation tank or a pit in the ground near the wellhead;

- installation of pumping equipment - located between the reservoir and the well.

Then a thief is installed in the pit, and water is supplied from the reservoir under pressure. The liquid erodes the rock, the drilling fluid is discharged by a mud pump into a container or flows into a pit along a dug trench for settling, re-sampling, and repeating the cycle.

The bailer is necessary when passing through hard rocks that water cannot handle on its own. After turning off the pump on the clays, the thief is rotated with levers, on coarse, gravelly soils, it is thrown into the well using a traveling system.

conclusions

Thus, the owner of a suburban area can choose the best option for manufacturing a water intake source without expensive equipment. The maximum production rate will be for wells created using the bailer method, manual drilling, and hydraulic rock breaking. The Abyssinian well is easier to build, but the flow rate will be lower.

Video: do-it-yourself water well