Shower trays: we study the features of use, their shapes and sizes

Modern small apartments and studio apartments often have an area bathroom small enough to prevent a standard bath or shower cabintherefore residents have to resort to various tricks to make their stay more comfortable. One of the options for solving such a problem is the arrangement of an open-type shower cabin, when there are no stationary walls and doors, and their functions are performed by enclosing building structures (walls, partitions, etc.) and a protective curtain. The only object of plumbing equipment, with the exception of a mixer and a shower head, in such a design will be a pallet that serves to receive and remove the used aqueous solutions. What are shower trays, their shapes and sizes, what materials are used in production, as well as advice on how to choose the right sample for a particular room - all this is in today's review of homemaster.techinfolux.com/en/.

The content of the article

- 1 Purpose and possible use cases

- 2 Types of products by material of manufacture

- 3 Shower tray shapes

- 4 Standard shower tray sizes

- 5 How to choose a shower tray - our editorial team's recommendations

- 6 The nuances of mounting small, medium and deep models

- 7 Features of making shower trays with your own hands

- 8 Video: choosing a shower tray

Purpose and possible use cases

The main purpose of shower trays is to ensure the normal operation of the shower cabin during its use, which consists in receiving and removing water and aqueous solutions used by a person during water procedures, as well as protecting the flooring from moisture on its surface. In addition, in various designs, placement and use, shower trays can perform the following tasks:

- to be the basis for the design of the shower cabin, its “foundation” - when installing protective fences and shutters;

- act as a heat-insulating layer - when the floor is made of stone and is cold;

- can be installed outside the bathroom and used in a narrowly focused purpose - for washing feet or pets after a walk.

By installing a shower tray in the hallway, you can easily wash your pets after a walk or clean your shoes from dirt

The use of pallets instead of a shower or bath has a number of advantages over them:

- Takes up little space and can be installed anywhere.

- A variety of sizes and shapes allows you to choose a model in accordance with the style of the room and the personal preferences of the user.

- Multifunctionality allows you to use it not even for its intended purpose.

- Ease of installation compared to other products.

- Low cost when compared to a bath or shower.

Manufacturers produce various models of similar products, differing in geometric dimensions and shape, used materials and colors. The production of shower trays is a whole branch of the plumbing industry, developed in Russia and other technically developed countries of the world.

The presence of a pallet allows minimizing the mechanical impact on the sewage system, which ensures the drainage of used water

Types of products by material of manufacture

There are various models on the plumbing market, made of steel and cast iron, acrylic and stone, as well as other materials that can meet the requirements for shower trays:

- resistance to mechanical stress;

- high rates of heat and sound insulation;

- wear resistance;

- ease of maintenance and care.

- Steel shower trays.

Models of this group are made of sheet steel, covered with an enamel layer. Their advantages include only low cost, and the disadvantages are:

- susceptibility to destruction and corrosion (enamel chipping and rusting);

- low rates of heat and sound insulation.

- Cast iron shower trays.

Cast iron models are not so common for individual use. Most of them are used in the arrangement of public buildings: hotels and swimming pools, bath complexes and sanatoriums. The reason for this is their positive properties:

- strength and durability;

- high degree of heat and sound insulation;

- not susceptible to corrosion.

The main disadvantage of cast iron products is their significant weight. All shower trays made of cast iron must comply with GOST 18297-96 “Enamelled cast iron sanitary devices. Technical conditions ".

- Acrylic models.

Acrylic is a modern popular material that has confidently conquered its niche and is used in the manufacture of baths, showers and other sanitary ware. It is characterized by all the advantages of cast iron and steel, besides, when using it, you can make products of any shape and configuration, as well as color and design style.

- Ceramic and glass models.

Trays made of ceramics and glass look very attractive, but they are fragile, and glass, moreover, require careful cleaning, which makes them difficult to use.

- Stone models.

Natural and artificial stone is used for manufacturing, but they are not as common as the products discussed above, due to the high cost of models made from natural raw materials and impracticality - made from artificial components.

Related article:

Shower cabin with bath. Varieties, features, standard sizes, advantages and disadvantages, functionality, an overview of popular models and consumer reviews - read the publication.

Shower tray shapes

The shape of pallets can be very diverse and depends on the designer of the company that produces them and the possibility of installation in the place of placement.

Various models are:

- square and rectangular;

- round or oval, made along a certain radius;

- in the form of polygons and asymmetric shapes.

Acrylic shower tray with dimensions 900 × 900 mm of the BAS Diamant series, made in the form of a pentagon

Corner shower trays with a rounded outer part are most suitable for small bathrooms, while other models can be placed in different ways, depending on the wishes of the user and the purpose of the product.

Standard shower tray sizes

Manufacturers of plumbing fixtures produce shower trays in standard and custom sizes. This is due to the fact that standard sizes correspond to other products used in equipping bathrooms (curtains, door sashes, etc.), which simplify the arrangement of such rooms, and non-standard ones allow you to create an individual style when decorating the interior space of premises.

Standard models of shower trays are available in the following sizes:

- 70 × 70 and 80 × 80, 90 × 90 and 130 × 130 centimeters - for equilateral, made in the form of a rectangle, polygon and with a rounded front side;

- 70 × 90 and 70 × 130, 80 × 130 and 90 × 130 centimeters - for those made in different shapes.

Non-standard sizes can be completely different, because they are determined purely individually.

Another dimension that determines the functionality of the shower tray is its height.

According to this indicator, the models are classified as follows:

- small - the depth is up to 4 cm;

- average - depth from 4 to 18 cm;

- deep - more than 18 cm deep.

Deep pallets are most in demand in families with small children. the volume of the product allows you to take a bath in it, and small ones are convenient for the elderly, because it is not difficult to enter its surface.

How to choose a shower tray - our editorial team's recommendations

Due to the fact that a wide selection of various pallets is presented on the market for such products, it is sometimes difficult for an unprepared user to choose the required model. In this case, sales consultants, experienced users who tell about the experience of using a particular model, as well as advice from specialists in this area of technical products and devices, come to the rescue.

Model "QUICKR" from the "Showering ByGlass" series is made of acrylic in standard geometric dimensions

The specialists of our editorial office can also provide assistance in this matter, and this is what we recommend:

- The overall dimensions of the shower tray must correspond to its location.

- The product should be located in such a way as to minimize the work on the supply of engineering communications (water supply, hot water supply system, sewage).

- The use of the shower should be comfortable for all family members, therefore, special attention should be paid to the depth of the tray.

- Small models require the installation of sewer pipes inside the floor covering, which is associated with certain technical difficulties that should be anticipated at the time of purchase.

- The pallet must be easy to maintain so as not to cause difficulties for the user.

- When installing the pallet against the wall, the places of their interface must be treated with sealants.

Which shower tray is better - this is decided by each user purely individually, in accordance with their individual preferences and financial capabilities.

Related article:

Bathroom design: modern ideas. In this publication, we will consider design in styles: classic, loft, retro, art deco, as well as the choice of furniture, materials for decoration, lighting organization, expert advice.

The nuances of mounting small, medium and deep models

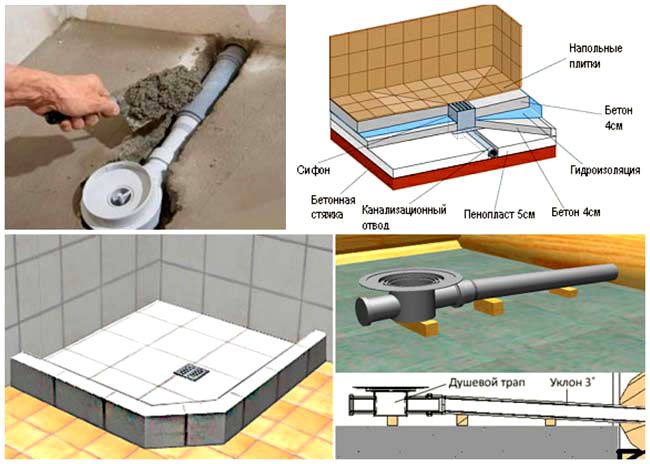

The installation of shower trays of various depths is carried out somewhat differently, which is associated with the method of placing such products on the floor surface and their fastening. Deep models, made of acrylic, steel or cast iron, are placed on a frame, which ensures their reliable fixation in the horizontal plane. The presence of a frame allows you to place sewer pipes in its internal space and siphon, installed at the outlet of the pallet receiving hole, which is convenient for installation and further maintenance. Medium depth models are mounted on a special stand or podium, which also makes it easy to connect them to utility networks. Some products are equipped with special legs that allow you to set the pallet in a given plane.

The most difficult thing is to connect small pallets, because this requires an accurate marking of the inlet in the floor, corresponding to the location of the drain of the pallet in relation to the building enclosing structures (walls, partitions, etc.).

Features of making shower trays with your own hands

The shower tray can be made with your own hands, using a concrete solution, ceramic tiles and other building materials. In this case, it is necessary to remember about some of the features of the operation of such structures, which affect their manufacture:

- on the base of the floor (subfloor, floor slab and other building elements), it is necessary to lay a layer of solid insulation, which can be used as polystyrene, expanded polystyrene or their analogues - this will provide the necessary thermal insulation of the structure;

- presence of cement (concrete) screeds on top of the insulation will ensure the alignment of the prepared base;

- waterproofing - one of the most important elements of the product under construction, because it is she who provides protection against moisture penetration to building structures;

Features of the manufacture of a shower tray from concrete and ceramic tiles - a diagram and some details

- with the help of the second layer of concrete, the specified slopes are created in the direction of the installed gangway;

- finishing (tiles or other finishing material) must have a water-repellent effect;

- when laying sewer pipes, their angle of inclination should be at least 3˚ from the ladder towards the receiving sewer pipe;

- along the perimeter of the pallet being constructed, it is necessary to make a collar to ensure that water does not penetrate from the interior of the structure to be assembled.

For the finishing of a do-it-yourself shower tray, various materials can be used - tiles, smalt, natural and artificial stone

Due to the fact that the market of sanitary ware is quite saturated, pallets for shower cabins can be bought in any corner of our country. They are sold both by large retail chains and by small stores specializing in the sale of sanitary ware and building materials. In such organizations, you can get expert advice, as well as choose your favorite model from the product catalog of a certain manufacturer, where you can find out the main characteristics of the device, overall dimensions and prices.

In large retail chains and specialized stores there is a wider choice of models, in addition, here you can always order a shower tray from the catalog