Preparing pipes for winter: which insulation to choose

When the question is raised, which insulation for pipes is better to use, it is necessary to study all the features of existing types. In today's publication, the homemaster.techinfolux.com/en/ editorial staff will analyze in detail all possible options, and also acquaint the reader with the technical requirements that an insulator must meet.

The content of the article

- 1 Thermal insulation function for pipes: is it needed

- 2 Operational features of materials for thermal insulation of pipes, which are distinguished by types

- 3 What are the requirements for insulating materials for pipes

- 4 Insulation material selection rules

- 5 Self-installation of insulation on stationary heating pipes

- 6 Video: pipe insulation

Thermal insulation function for pipes: is it needed

The effectiveness of insulating water pipes and other types of highways has been proven for a long time. In regions with harsh climatic conditions, it is imperative to use insulation. It prevents pipes from bursting during severe frosts.

If the insulation is performed for the heating main, then this will help to eliminate heat loss as much as possible when pipes are introduced into houses and other heated rooms.

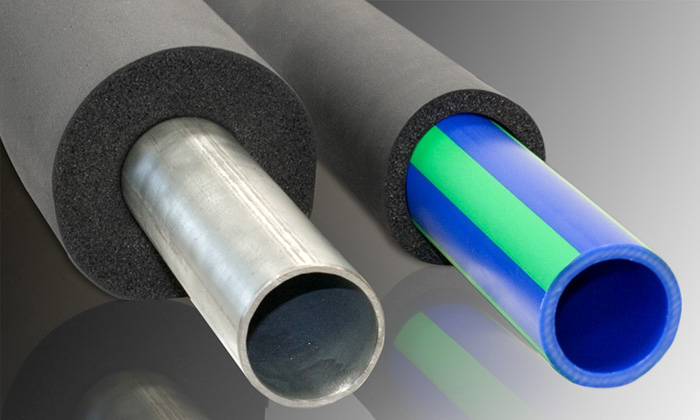

The insulation connection can be made as a cut. A special adhesive tape is used to secure it.

PHOTO: kti.by

As for the sewer systems, they also require mandatory insulation. This is done in case the sewer is equipped without a slope. Even when properly organized, waste lines need isolation. Biological deposits can build up in any of the compartments. They can subsequently freeze in freezing weather, which will lead to inevitable cracks in the pipes.

With the correct organization of thermal insulation, pipes will be brought into the room with minimal loss of thermal energy.

Typically, for a metal structure, insulation is used with a sufficient thickness

PHOTO: russian.alibaba.com

Operational features of materials for thermal insulation of pipes, which are distinguished by types

Each of the insulation options has its own characteristics, properties, as well as pros and cons. Some are not suitable for all types of metal structures. Therefore, it is important to know which type is better to choose, taking into account the main features.

Mineral wool

This is one option that has little cost. At the same time, cotton wool consists of natural materials and has a high degree of thermal insulation efficiency. The composition of mineral wool includes fiberglass or any other natural stone. Also basalt material should be attributed to mineral insulators. All canvases of natural origin are distinguished by the following features:

- resistant to high temperatures;

- do not succumb to aggressive chemicals;

- after deformation, it completely restores its shape;

- easy to assemble.

However, it is better not to operate this material in high humidity conditions. Gradually mineral wool absorbs condensate, after which it freezes and creates a risk for the integrity of the pipe.

Penoizol

Penoizol is one of the expensive products that are used for industrial-scale highways. To use this type of insulation, it is necessary to purchase special equipment that will spray the material.

The features of such raw materials include:

- quick and easy installation;

- does not need additional fastening;

- resistance to frost and high temperatures;

- low thermal conductivity.

Alternatively, you can use polyurethane foam. It has similar characteristics and can be used for insulating a small section of the pipeline.

Foamed polyurethane

This type of material is applied by spraying using a special machine. Suitable for any surface, including pipes. It adheres perfectly to it, as it has increased adhesion.

Positive characteristics include:

- fast and accurate installation;

- hardening for a few minutes;

- ensuring complete tightness.

In addition, the material does not require special preparation before use. Excellent resistance to many types of mechanical stress. Has a high degree of fire safety.

Foamed polyethylene

If we compare the material with other heaters, then this type is considered one of the most advanced. He is distinguished by the following abilities:

- withstands the load on the material;

- after deformation, it takes its original shape;

- withstands exposure to materials such as cement, lime;

- operates in the temperature range from + 90 ° C to -60 ° C;

- refractory material.

During installation, the material is cut lengthwise, and after being put on the pipe, it is glued with a special bandage. It is sold in rolls or tubes 6 m long.

Expanded polystyrene

This material is also considered highly effective. It contains more than half of the air. It is inferior in strength to other insulators. Available in semi-cylinders. Positive properties include:

- long service life;

- fire safety;

- the possibility of repeated use;

- possibility of operation at high temperatures.

For maximum retention of thermal energy, additional installation of cork insulation on pipes is practiced.

Energoflex for pipes is used as follows: the thinner the pipe, the thicker the material

PHOTO: climatik.su

Energoflex

The basis for the production of Energoflex is polypropylene. The development technology provides for high pressure. In appearance, the structure resembles pores with air pores.This raw material has the following features:

- effectively functions when exposed to temperatures in the range of -60 ° C - + 90 ° C;

- this material does not react at all to alkalis, acids and other chemical constituents;

- the product can be actively used for 25 years;

- possesses water-repellent properties.

However, this material is not suitable for use in constant sunlight.

On a note! Each of the heaters for pipes does not lend itself to decay, so they can be safely installed on pipelines immersed in the soil.

Penofol must be used wisely, too narrow materials should not be used for pipes with a large circular cross-section

PHOTO: vashslesar.ru

Foil penofol

Foiled penofol has been used for many years. It has good qualities and an attractive price. Sold in rolls with a self-adhesive base. In order to fix it on the pipe, you must first clean it of dust, debris and dry it well. This is the only way to guarantee the tightness of the pasting.

When pasting, make sure that there are no overlaps. Such material is fastened only joint to joint, smoothing well and making the joint as tight as possible.

Heat insulating paint

Coloring agent is a good option for insulating pipes that carry heating. This composition allows you to replace a five-centimeter layer of mineral wool. This will make it possible to free up the area around the highway. Thermal insulating paint is capable of functioning in the temperature range from -60 ° C to + 250 ° C.

Also resists the development of fungus, mold, does not accumulate dampness. As a result, the pipeline is hermetically sealed, so the formation of corrosion and rust can be excluded.

Other materials

Among other options that are successfully used for thermal insulation of various highways, the most durable and high-quality are considered:

- expanded clay;

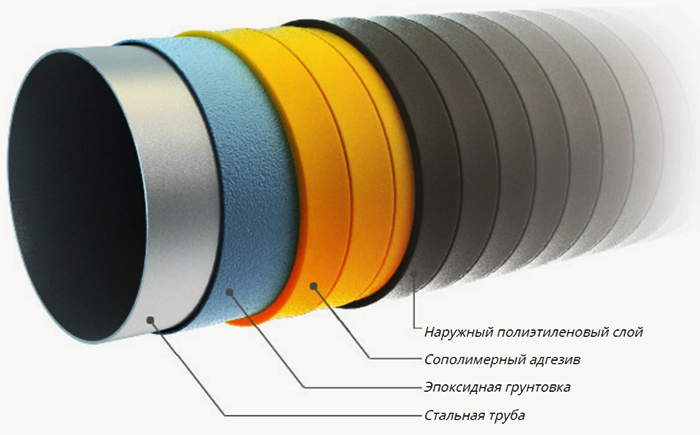

- finished pipes with insulation;

- stone wool;

- Styrofoam;

- foamed rubber;

- various kinds of liquid heaters.

Regardless of how the pipeline is laid: aboveground or underground, thermal insulation must be installed.

What are the requirements for insulating materials for pipes

In order for a thermal insulating agent to perform its direct function, it is necessary that it meets certain requirements.

- Low value of thermal conductivity. This is the main factor responsible for effective thermal insulation.

- Resistance of the material to chemical reagents. For example, when fertilizing the soil during planting, a large amount of substances penetrate into the lower layers of the soil, where the decomposition process takes place. This can damage the insulation.

- Hydrophobicity. The material should not absorb moisture. With the onset of frost, it will begin to harden and deform, which will cause the pipe to rupture.

- Good breathability. This requirement applies equally to both hard and soft insulating materials. If the indicator is low, then the thermal conductivity will increase, which, naturally, will cause a deterioration in the thermal insulation properties.

Otherwise, each material must have a clear description on the packaging. Depending on the type of line, the purpose of the raw material and its thickness are taken into account.

There are options for pipes that are produced at the factory immediately with a layer of thermal insulation

PHOTO: offthevylc.ru

Insulation material selection rules

To protect the pipelines from cold penetration, it is important to understand the conditions under which the pipelines are laid, what functionality they perform.Depending on this, they stop the choice on one or another tool.

For water mains

If the water supply runs outside or is in an unheated room, it needs the same insulation layer. It is desirable that this composition is sufficiently breathable and light. It should not collect moisture from condensation. The following insulators correspond to these properties:

- foil-clad penofol;

- expanded polystyrene;

- foamed polyurethane.

These materials are also suitable for thermal insulation of pipelines in deep soil layers.

For heating systems

To improve the operational properties of heating, different types of insulation are used for pipelines with a heat carrier. Often among them there are:

- PPU shell;

- mineral or basalt wool;

- expanded clay;

- penoizol.

Most often, for such lines, a winding is additionally made of foil-clad compositions.

For sewerage

Fiber materials are best for drainage systems. Also suitable are polyurethane foam and polystyrene foam shells. In the case of an industrial scale insulation, they try to give preference to basalt wool or expanded clay.

Self-installation of insulation on stationary heating pipes

Many of us use public heating rather than autonomous heating. But without proper pipe insulation, it will be impossible to achieve the desired temperature. Therefore, everything should be done in stages. Let's analyze the instructions using the example of a street pipe with leaky insulation.

In the same way, we carry out the insulation of the entire main pipe.

Dear readers, if you still have questions about the choice of insulating material or are interested in the advice of professionals, be sure to write in the comments under the article. Also, don't forget to rate the post.