What are the metal crimp clamps: the difference between fasteners and repair

A metal clamp as a fastening element or device used for repair work has found wide application in various spheres of human activity - from the installation and repair of pipelines for various purposes to use in household appliances and vehicles of various types. Few know what metal crimp clamps are and how to use them correctly. Let's take a closer look at all the points related to the use of such mounts in the review of the homemaster.techinfolux.com/en/ edition.

The content of the article

What is the difference between fastening models and repair

Clamps manufactured by our industry, according to their purpose, are classified as fastening and repair, and the name itself defines their purpose, which is their main difference. Fastening models are designed for fixing pipelines at a given location for further operation.

Their main functions are:

- strength and reliability of fixing the pipes being mounted;

- ease of installation and long service life;

- prevention of lateral displacement of the pipeline system with the possibility of longitudinal movement during use.

Repair clamps are used to repair pipes when it is impossible to repair the damage in any other way, or it should be done quickly, without stopping the circulation of fluid in the damaged pipeline. The main requirements for repair models that determine their purpose are:

- ease of use and the ability to quickly perform installation work;

- reliability and long service life.

Using repair models, you can repair pipes made of various materials: steel and plastic, asbestos cement or cast iron for various types of damage: fistulas and fractures, cracks, mechanical damage and other malfunctions.

Repair models made of stainless steel will ensure quick repair work and will not spoil the visual perception of the room where they will be installed

Metal steel pipe clamps

Fastening clamps are made of various types of metal and differ in geometric dimensions, design and type of fixation.

Main technical parameters and material of manufacture

In the manufacture of metal clamps, stainless or carbon steel is used with a protective layer against corrosion (zinc or other material). The main technical characteristics of such products are:

- standard size that determines the diameter of the pipe to be fixed (measured in inches);

- thickness (measured in mm);

- the size of the connecting nut (if any);

- workload (measured in kilonewtons);

- breaking load (measured in kilonewtons).

Structurally, the fastening elements can support a different number of pipes simultaneously with their parallel laying

Constructional forms and type of fixation

The type of fixation provided on the product determines the type of pipeline on which a particular model can be used, as well as its purpose. There are two types of fixation:

- rigid (motionless) - performed in places of bends and branches in water supply and sewerage systems;

- floating (movable) - it is used in heating and hot water supply networks, where longitudinal displacements of pipes during operation are possible, associated with a change in the temperature regime of the systems.

By design (shape), metal fastening clamps are of the following types:

- split ring;

- two half rings;

- U-shaped bracket.

The U-shaped bracket is made for each standard size of pipes, which allows you to choose the necessary fastening element for pipelines of different diameters

Types of crimping metal pipe clamps

The type of crimped metal products determines their purpose and design features. They can be classified as follows:

- spiral - to fix it, it is necessary to turn clockwise or counterclockwise, used on water supply networks made of reinforced plastic pipes;

- power clamp - this is a metal tape equipped with a tightening structure, can be used for fixing and repairing pipelines of various geometric shapes (circle, square) and for various purposes;

- reinforced fasteners - it is used for various types of hoses and hoses, it is a metal lock connected to a metal tape;

- wire mount - made in the form of several rings of wire, connected by a mechanism for tightening them;

- worm clamp - this is a metal strip with cuts (track) applied on its surface, equipped with a screw to tighten the strip;

- pipe clamp - made in the form of two half-rings, one of which is equipped with an element for fastening to building structures and screws for their fastening;

- spring clamp - used in DHW networks and heating, is a metal strip with applied holes, twisted under a certain diameter;

- with rubber seal - can be equipped with various types of clamps, discussed above, which provides fastening strength and tightness for models used for repair purposes.

Clamps of the "reinforced fastener" type are also called power hinge devices, which is due to their design and the principle of operation of the fastening element.Worm gear models can be referred to as band metal clamps, which is also related to their design. Wire products can be referred to as spiral, therefore, when choosing a model, you need to be guided by these names. All types of clamps can be produced in a reinforced design, which is expressed in the dimensions of the materials used (thickness and diameter), as well as the design of the tightening mechanisms.

Standard crimp sizes

Standard sizes of clamps, as well as technical requirements for them, are regulated by GOST 28191-89 “Clamps for hoses. Technical conditions ". The main dimensions of various types of products are summarized in the following table:

| View | Series | Diameter, mm | Thickness, mm | Tightening torque / working load, Nm / kN |

|---|---|---|---|---|

| Worm | Easy | 8-16 | 0,4-0,8 | 2 |

| 12-20 | 3 | |||

| 16-160 | 0,5-1 | |||

| Over 160 | ||||

| Heavy (reinforced) | 16-160 and above | 0,5-1 | 5 | |

| Wire | - | 18-40 | - | 0,2 |

| 40-60 | - | 0,3 | ||

| 60-85 | - | |||

| Pipe | - | 11-36 | 1 | 1,4 |

| 36-65 | 1,2 | 1,6 | ||

| 80-116 | 1,5 | 2,4 | ||

| 122-219 | 2 | 2,6 |

Features of crimp models for large diameter pipes

A distinctive feature of crimp models that you should pay attention to when choosing them for large-diameter pipes is the thickness of the band, which is a collar that protects the pipe from damage during its installation. In the manufacture of the cuff, corrugated rubber is used, which not only prevents possible damage to the pipelines while tightening the clamps, but also helps to reduce vibration and noise levels during the operation of pipeline networks.

Repair clamps for pipelines

Models intended for repair work are classified by design and material from which they are made.

The main technical indicators that determine the possibility of using this repair device are:

- working diameter - determining the standard size of the pipe on which it can be used;

- length - determines the size on which a specific model of the device can fit and fix the malfunction.

The main document governing the production and use of repair clamps is GOST 24137-80 “Pipeline fastening details. Clamps. Design and dimensions ", as well as GOST 28191-89" Clamps for hoses. Technical conditions ".

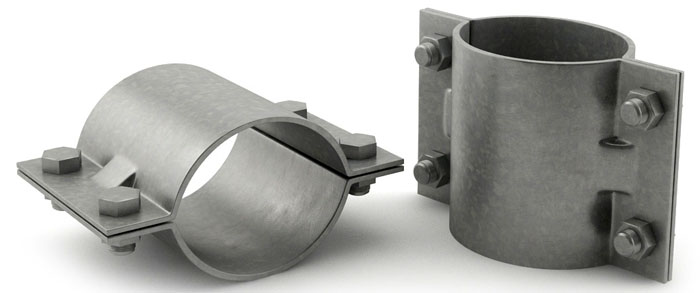

In accordance with the classification, repair clamps are subdivided:

- By design on:

- unilateral - are a U-shaped tape with perforation in the upper part, by means of which the clamp is fixed on the pipeline;

- bilateral - made in the form of two identical halves in the form of half-rings, connected to the pipe using fasteners;

- multi-component - consist of several segments and are used on large diameter pipelines.

- Based on materials on:

- steel - are made of various types of steel (carbon, stainless, alloy) and are resistant to corrosion and long service life;

- cast iron - are made of cast iron, are durable and durable.

In addition, when choosing a repair model, it must be remembered that the pressure in household pipeline networks can reach 10 atmospheres, and the temperature of the coolant can be 120˚С.

Metal hose clamps

When using hoses as a pipeline system, worm-type products and devices of the "reinforced fastener" type, which were described above, are used to connect them. For high-pressure hoses, the “reinforced fastener” series is the best choice. clamps of this type are the most durable, both in terms of their design and in relation to the coupling of the elements of the pipe system.

Various types of clamps are produced by a large number of domestic companies, both specializing in the production of fasteners and similar structures, and those for which these products are associated, made from waste of the main production. A variety of types and models designed for different types of use and operation, allows you to choose and purchase the necessary product that meets all the requirements for it in a given price range.