Why is a hydraulic accumulator useful for water supply systems?

Failure of autonomous communications in a private house is a common phenomenon, since equipment with limited load is used. In most cases, troubles can be avoided by using various compensatory mechanisms. For example, a hydraulic accumulator for water supply systems provides an even water supply and a supply of liquid in case the electric pump is turned off, which increases the service life of the pipeline connected to the equipment system, eliminates the problem of water interruptions. Let's figure out how he does it, whether it is necessary in the house, how to choose the right model and what to look for during installation.

The content of the article

Description of the device

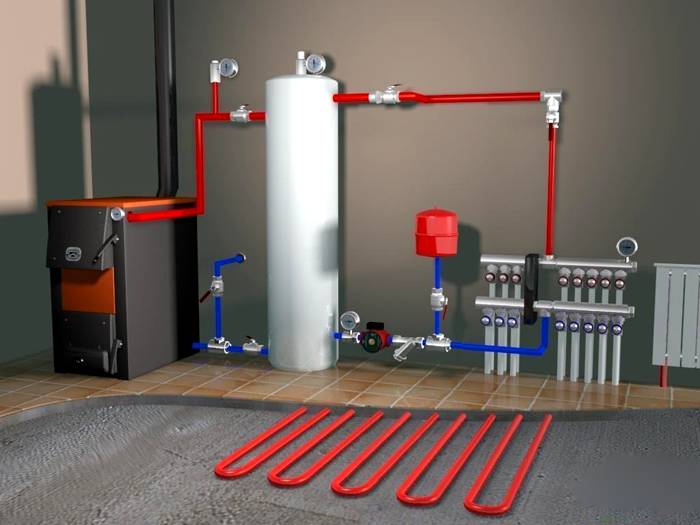

Heating in a private house is a closed system with a constant amount of water. When heated, it expands and presses from the inside on pipes, hoses, taps and fuses of the connected mechanisms. A powerful pump or large volume boiler in the water cycle also assumes a high level of pressure when the water is turned on. Continuous sharp fluctuations create the risk of pipeline rupture and equipment breakdown.

With a pressure difference in the boiler and pipes, the inclusion of water can provoke a strong water hammer

Accumulator functions

- An additional water storage of a special design assumes excess pressure, eliminating the risk of damage associated with its occurrence.

- Prolongs the service life of pipes, connections, boiler heat accumulators, filters, washing machines etc. by maintaining a constant pressure.

- Reduces the number of pump starts and stops, minimizes pump wear.

- Depending on the model, the accumulator holds up to 300 liters of water, which can be used in the event of a power outage.

- Maintains an even head during periods of peak demand and when the pump starts and stops.

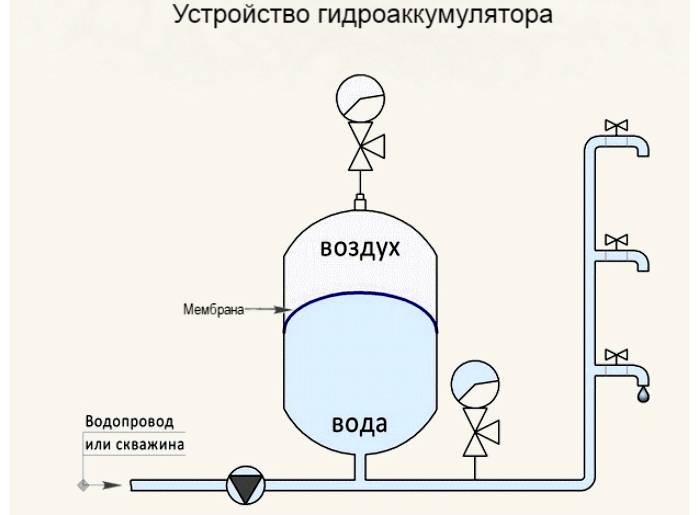

What is the structure

The volume of the expansion tank is partly filled with water and partly with air. They are separated by a food-grade rubber membrane or water is collected in a rubber cylinder. When the tap is opened, water enters the system, which is displaced by compressed air.

Automatic relay determines the decrease in air pressure in the accumulator below the set minimum due to the emptying of the tank and gives a signal to turn on the pump and refill fluid. When the initial air compression value is reached, it switches off. If there is a slight drop in pressure, the pump will not start. That is, a small water intake does not lead to the launch of the entire system, but only starting from the accumulator. This reduces wear and tear and electricity consumption.

Helpful information! If the pressure of 1.5 bar is not enough for the normal functioning of the system due to its large volume and height, for example, in a 3-4-storey building, through the spool valve in the upper part of the tank, it can be pumped to the required level with a conventional car pump.

The accumulator has fastenings that correspond to the method of its placement ─ on the floor or on the wall. Outside coated with anti-corrosion epoxy paint or other protective coating. Operating parameters such as preset and maximum pressure, permissible water temperature, diameter of the water inlet are indicated on each unit. These characteristics are selected in accordance with the purpose of the battery and the specific features of the customer's water supply system.

Note! The service life of household devices declared by manufacturers is on average 7-10 years. But in practice, it depends on the initial conditions, the availability of replacement parts and, as a rule, does not exceed 7 years. The simplest ones last 3-4 years.

How to choose a hydraulic tank for water supply systems

The volume of household batteries varies from 6 to 500 liters; devices of larger size are practically not used in private houses. The membrane material determines whether the model can be used in a heating system or only in cold water supply. Synthetic rubber withstands an average temperature range of -10 ° C to + 100 ° C, and natural rubber up to + 50 ° C.

Models and prices

- Tanks without fasteners. Small devices with a volume of 5 to 24 liters are installed vertically, directly on the pipe. For reliability, you can use a special bracket, which consists of a wall mount and a ring to put on the battery.

- Tanks with universal fasteners... Hydraulic accumulators for water supply systems up to 50 liters are often produced with a mechanism suitable for both horizontal and vertical installation. Placed on the floor when it is not possible to fix the device on the wall for reasons of ergonomics or technical reasons.

A flat platform on the accumulator is designed for installing a pump on it, helps to optimize the location of the hydraulic unit

- Legged tanks. Devices from 80 liters are too heavy when filled and are only installed on the floor. As a rule, they have three stable stops. Versions with metal or plastic connecting flange at the bottom are available.

Regardless of the installation method, the expansion tanks are equipped with a nipple that serves not only for pumping and increasing pressure, but also for venting excess air that gets inside with water and unbalances the operation of the unit. The presence of a replaceable membrane, which breaks down the fastest, prolongs the life of the product.

Devices without a replaceable cylinder are cheaper, but they are designed for light loads and short-term operation

Prices for hydroaccumulators for water supply start at an average of 700 rubles. for 8 liters and reach 25'000 rubles. for 500 liters. Popular brands are Russian Gileks, Wester and Uni─Fitt, Reflex and Zilmet of German production. European products are 10-15% more expensive. For Russian conditions, they are not always the best choice.

Related article:

Pressure switch for the accumulator. Competent installation and adjustment of the pressure switch for the accumulator can reduce the negative impact on the equipment. And everyone can cope with this, thanks to our step-by-step instructions.

Selection factors

- The volume of the water supply system. The minimum accumulator size is 10% of the total liquid in the pipes. For example, if the system has 220-230 liters, then the tank can be 20-30 liters. For heating using a solid fuel boiler, you need to take a tank 2 times larger, since the water heats up quickly, the pressure rises sharply, and additional volume is required to compensate for the expansion of the coolant.

A gas, diesel or electric boiler heats water smoothly and does not require such a large expander as a gas

- Pump characteristics. The higher the pumping volume per minute, the larger the battery. Since the hydraulic tank is filled with water only 35-65%, it can be conditionally considered necessary its size, 2-2.5 times the pump capacity. For example, when pumping out 30 l / min, it is recommended to purchase an expander from 60 l.

- Maximum one-time water consumption. The use of a hydro accumulator tank for cold water supply will provide an even head if its displacement is 2 times the peak water intake.

- Are anti-freeze or other synthetic substances used in the heating pipes? When heated, they expand more than water, so the expansion tank should not be 10%, but at least 15% of the total volume of the system.

Helpful information! The larger the displacement of the battery, the less often the pump turns on and off. To increase the working life of the equipment, it makes sense, if possible, to purchase not the minimum required hydraulic tank, but a larger one.

Related article:

Adjusting the water pressure switch for the pump... A practical guide for the correct setting of the pressure switch for the pump with photo and video examples in a special publication.

Installation and operation of a hydraulic accumulator for water supply systems

The preparatory work consists of choosing an installation site and flushing the entire system to remove air capsules. The expansion tank is mounted in a warm room, on a flat surface, as close as possible to the pump. Apparatus that combine both devices are also on sale. The location should allow for unimpeded service: checking pressure, changing diaphragm, venting or pumping air.

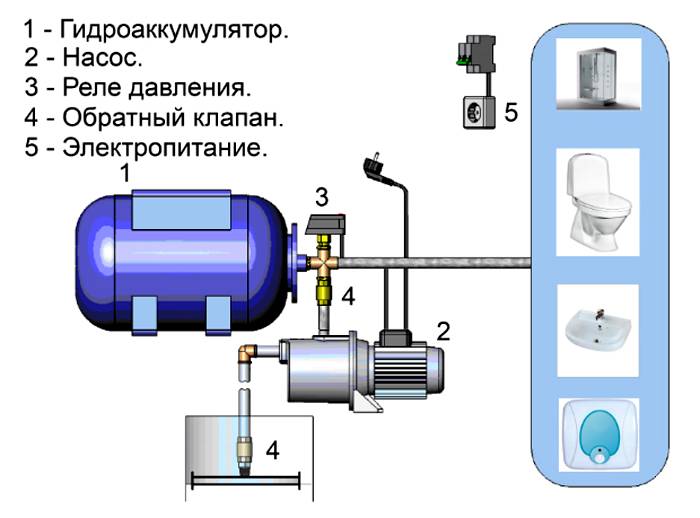

How to connect a hydraulic accumulator to a pumping station and pipes

- Check the initial pressure in the tank, bleed or replenish if necessary.

There are devices with a built-in pressure gauge on sale, to the rest it is connected through a spool

- Connect the 5-way connector to the battery. When placed on a wall, pipe sections at an angle of 45 ° and corner elements are used for this, so that the container is sufficiently far away from the wall.

- Additionally, install a ball valve to shut off the water in case of replacement of the tank, membrane or leaks.

- Connect the automatic relay, pump, outlet pipe and pressure gauge to the fitting.

Connect the seams by welding or compression fittings ─ depending on the piping material ─ and seal.

- Start up the system and check carefully for leaks.

Helpful information! To understand what pressure should be in the accumulator at the time of installation, it is necessary to check the pump characteristics ─ the expander must provide a minimum number of bars for the automatic switching relay to operate.

If the water supply is intermittent, then the air compression force set during installation does not correspond to the size of the system. The new indicator is calculated as the distance between the tank and the highest point of the pipeline in meters, add 6, divided by 10. The resulting figure is the required number of bars. To maintain an even air pressure in the expansion tank, it is recommended to measure it at least once every 2-3 months.

A hydraulic accumulator for water supply systems is not a strictly necessary element in the house, but its presence guarantees compliance with modern standards. Benefits on the face:

- even water pressure;

- long service life of pumping equipment;

- elimination of the risk of pipe breaks and leaks;

- stock for unforeseen cases;

- small price and easy installation.

Video: water supply and hydraulic accumulator in a private house