How to return the old look to plumbing: choose a high-quality acrylic liner in the bath

Before you start replacement of plumbing in the bathroom, pay attention to the condition of the acrylic liner. This product hides all defects, giving the bathtub surface a beautiful and neat look. The liner needs to be changed from time to time. To choose a quality sample, you should study the advantages and disadvantages, as well as find out how the tabs are installed and what features the insulating material has.

The content of the article

- 1 What You Need to Know About Acrylic Bathtub Cover: Key Features

- 2 Advantages and Disadvantages of Acrylic Bath Liner

- 3 Materials used to make acrylic inlays in cast iron and steel tub

- 4 Performance characteristics of acrylic liners by type

- 5 Bathtub acrylic inlay manufacturers

- 6 The procedure for determining the size of the insert if you decide to buy an acrylic insert in the bath without installation

- 7 Acrylic insert or bath replacement: choose the right option

- 8 How to install an acrylic insert in a bathtub: sequence of actions

- 9 Care rules

- 10 Bathtub restoration with liquid acrylic: advantages and disadvantages of the method

- 11 What determines the price of an acrylic bath liner

What You Need to Know About Acrylic Bathtub Cover: Key Features

Bath liners were invented several decades ago, and today they are widely used both abroad and in Russia. With their help, you can give an old bathtub a decent look without spending a lot of money.

PHOTO: stroyportal.ru

Bathtub restoration with linings is comparatively cheaper than buying new plumbing

In order to restore the inner surface of an old bath, it is best to use special tools - acrylic pads. This is a cover that needs to be attached from above. In just a few hours, the product's appearance and performance are restored and the bath returns to its normal appearance.

Advantages and Disadvantages of Acrylic Bath Liner

Advantages of the method of restoring the surface of the bath using pads:

- installing the cover and updating the bath takes no more than two hours, repair and installation are simple, but special equipment is needed;

- the ability to correct serious defects such as stagnant water and incorrect slope;

- during the restoration process, it is not required to touch the walls and other surfaces in the room;

- economy is the main plus. Installing a new bathtub is much more expensive than updating an old one;

- the material has low thermal conductivity, due to which the water collected in the bath cools down more slowly;

- the service life of the bath is increased to 15 years;

- a coated bathtub is much easier to remove dirt and plaque;

- the surface of the bath is completely restored, even if there were deep cracks on it.

PHOTO: blitz-remont.ru

There are several shade options to choose from, you can easily choose a patch that matches the color

But acrylic inserts also have some disadvantages:

- in order to care for the treated surface, you need to use special products;

- restoration of a damaged insert is completely impossible, so it is changed;

- the mechanical strength of the linings is not high. Damage can appear if a pet jumps into the bath and grabs its claws, or a bottle of shampoo falls;

- if the installation is done incorrectly, the tightness of the liner is usually broken. Because of this, moisture accumulates under the bottom, which after a few months leads to the formation of fungus.

Materials used to make acrylic inlays in cast iron and steel tub

The technology for the production of acrylic inlays assumes that the already cut sheets will be laid on a special molding machine. Then the workpiece is heated to a certain temperature, it becomes plastic and is immediately applied to the bath, taking the desired shape.

The total cost of the work depends on what material is used. Most often in the production of inserts used:

- PMMA (polymethyl methacrylate)... This type of raw material is also called plexiglass, it is thermoplastic. PMMA has a snow-white, smooth surface and is highly abrasion resistant. Under the influence of chemicals, quick deterioration of the insert does not occur;

- ABS plastic... It is an impact-resistant and thermoplastic resin-based material.

PHOTO: expert-n.info

With the right choice of material for the insert, long-term operation and a guarantee against surface abrasion and damage are ensured

Performance characteristics of acrylic liners by type

Depending on what material was used to create the insert, you can say with almost 100% accuracy how long it will last and what properties it will have. Before choosing one type of material, you should familiarize yourself with all the main types and their characteristics.

Cast earbuds

Care of cast inlays is very easy and not painstaking, since they have a flat and smooth surface. There are small pores that quickly become clogged with dirt if left untreated, so it is recommended to wash the bath almost after every use. If contamination does appear, it can be easily removed.

The service life of the product is about 10 years. It is important that all the rules are observed during installation and the integrity of the material is not compromised.

Attention! The cost of the material for processing is no more than 30% of the cost of the whole bath.

It is important to consider that some manufacturers supply cheap molded inlays to the market. If funds are limited, they can also be used. But because acrylic sheets are very thin, surface damage can happen very quickly.

Low-quality acrylic also sells for a small price. You can distinguish poor quality acrylic from good acrylic by the presence of a yellowish tint and large pore size.A good insert should be smooth and flat.

Composite Liners

In the manufacture of this type of liner, two main components are used: acrylic and ABS plastic. The first one is applied in a thin layer on an already finished plastic base. Such a product outwardly practically does not differ from a cast one, but it costs less.

You should pay attention to such tabs if the cost of a pure acrylic tab is very high. However, such a product is not very durable. Average service life is 5 years. After this time, even the highest quality and well-installed product, the acrylic layer is erased.

Bathtub acrylic inlay manufacturers

When choosing acrylic liners for bath restoration, you should pay attention to several large and trusted manufacturers:

- LLC "ISKomp"... In the production of linings, a unique, in-house developed and patented method is used. All products are of high quality and certified. The client can choose a specific size and color.

- Plastall... The company supplies materials for the restoration of both cast iron and steel bathtubs. Several offices have been opened on the territory of Russia, in the countries of far and near abroad. The manufacturer offers liquid acrylic for restoration and ready-made inserts.

- SevenLux... The company's office is located in Togliatti. High-quality German equipment is used in the production. The technology is completely original, which is confirmed by the relevant certificates.

- "Multiplast"... High quality products are supplied that fully comply with all applicable standards and requirements.

PHOTO: ekonomihatti.com

Every high quality product made in official production must have a certificate

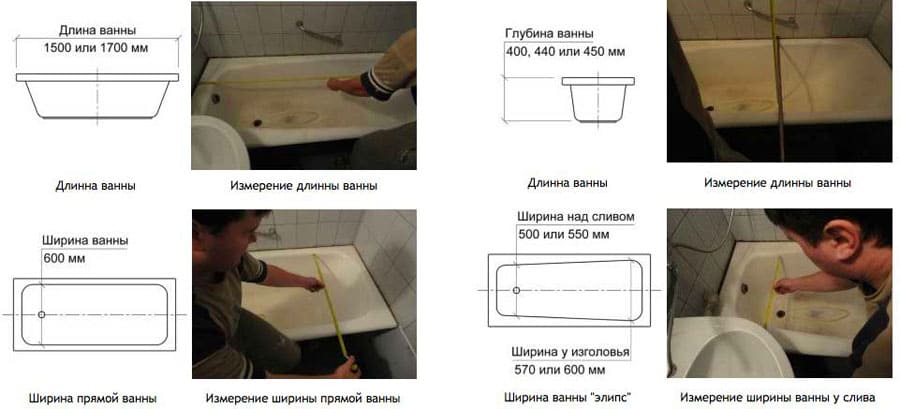

The procedure for determining the size of the insert if you decide to buy an acrylic insert in the bath without installation

If the price of the finished product is high, you can carry out the installation yourself by choosing a tab of a certain size. Pay attention to the following parameters:

- bath length, measured along the outer edge;

- bath length inside, without sides;

- depth, measured next to the drain;

- width at the head and above the drain.

PHOTO: static.tildacdn.com

Measurements must be carried out carefully to get the most accurate figure.

If all parameters have been determined, you can purchase the insert without installation.

Acrylic insert or bath replacement: choose the right option

To give the bathtub a normal look, you can purchase a new product or use acrylic inserts. The first option is preferable, however, if funds are limited, you can use overlays.

If the plans do not include bathroom overhaulthen inserting the liner may solve the problem for a while. Installation is carried out manually, and knowing the exact shade and dimensions of the bath, you can choose the most suitable insert.

Advice! In order for the insert to fit and serve for a long time, you need to choose the product that was produced at the factory.

How to choose an acrylic bath insert - our editorial team's recommendations

In order for the insert to serve for many years, when choosing, you should pay attention to several details:

- liner surface. It is important that it is smooth and silky to the touch, without large pores;

- the material should be white without any shades;

- thickness - the more the better. Acrylic bends slightly when pressed, but no more than 2-3 millimeters.

Advice! If the product fully meets all the requirements, you should check with the seller for the wall thickness and what material the insert is made of.

How to install an acrylic insert in a bathtub: sequence of actions

When doing the installation with your own hands, you need to follow the instructions clearly.

Bath preparation

Sequence of work:

Liner preparation

The insert must also be prepared before installation:

- The technological edge is cut to protect the insert.

- Using special nozzles, adjust the drain and overflow hole. It is necessary to accurately measure the space.

- Install a siphon. Make sure the connection is completely sealed.

Then the installation process begins:

Video: installing an acrylic liner in the bathroom

Care rules

You can extend the service life of the liner by taking good care of the product. To understand the intricacies of care, watch our video:

Related article:

How to wash an acrylic bathtub at home: suitable products, wipes and sponges, citric acid, vinegar, toothpaste; how to wash off yellowness, rust and limescale; than you can not wash an acrylic bath - read in the publication.

Bathtub restoration with liquid acrylic: advantages and disadvantages of the method

For standard bathtubs, restoration is not difficult, just use a ready-made insert in a suitable color. However, if the design is non-standard, the liner must be made to order, which greatly increases the cost.

An alternative is liquid acrylic. Its performance is much higher than that of epoxy paint. When carrying out work, acrylic is poured onto the surface and carefully spread over the surface.

What determines the price of an acrylic bath liner

The total cost of a product depends on several indicators: size, configuration, material and manufacturer.

Average cost:

| Product color and size | Prices without installation, rub. | Prices with installation, rub. |

|---|---|---|

| White, 150 cm | 3800 – 3950 | 5500-6500 |

| White, 170 cm | 3950-4100 | 5700-7000 |

| Colored, 150 cm | 3500-4100 | 5500-6500 |

| Colored, 170 cm | 3950-4100 | 5700-7000 |

You should also study the reviews on acrylic liners:

Feedback on the acrylic liner in the ISComp bath:

Feedback on the acrylic liner for the ISComp bath:

Tell us in the comments why you purchased an acrylic insert and what type of insert you chose.