Storm water inlets for storm sewers: removal of moisture from the building

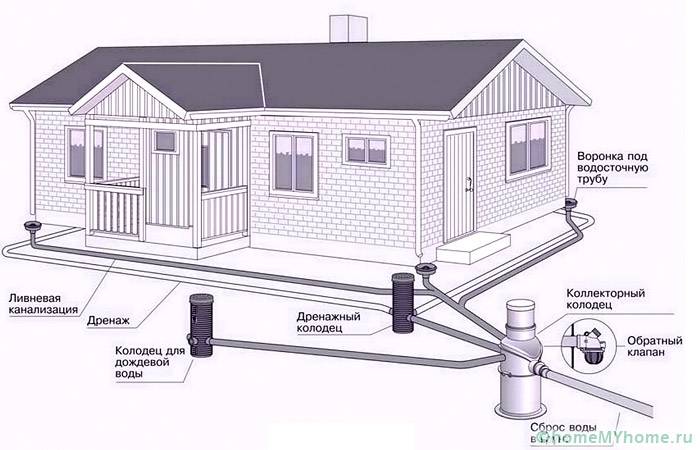

To remove atmospheric moisture directly from the house, special storm inlets are arranged next to the drainpipes. For storm sewers, they are the main collection points for water. The precipitation from the roof through the gutter enters the main pipelines, after which it enters the drainage system.

The content of the article

- 1 The structure of devices for receiving moisture

- 2 About each material of manufacture separately

- 3 Self-contained water collection point

- 4 Calculator for calculating the volume of storm water

- 5 Calculator for calculating the volume of storm water

- 6 The cost of plastic storm water inlets for storm sewers

- 7 Learn more about storm sewers

- 8 Summarizing

- 9 Video: installation of a storm water drainage system

The structure of devices for receiving moisture

There are many types of storm water inlets, which differ not only in size, but also in materials of manufacture. Products can be sold complete with sewer elements or separately. Due to the variety of execution options, their cost also varies significantly.

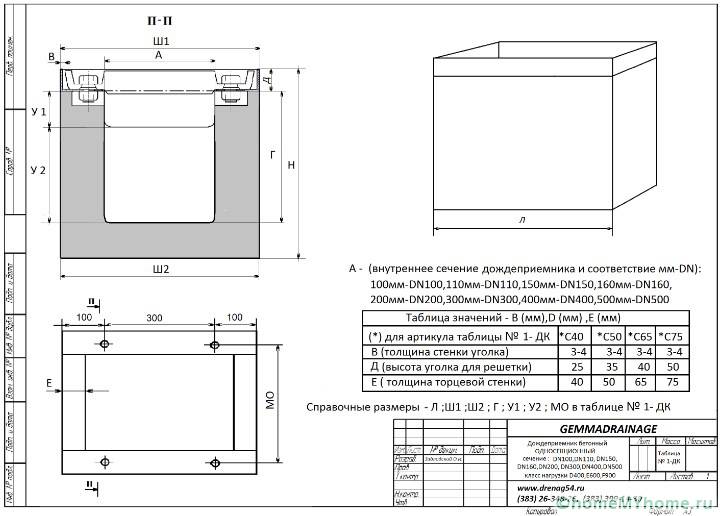

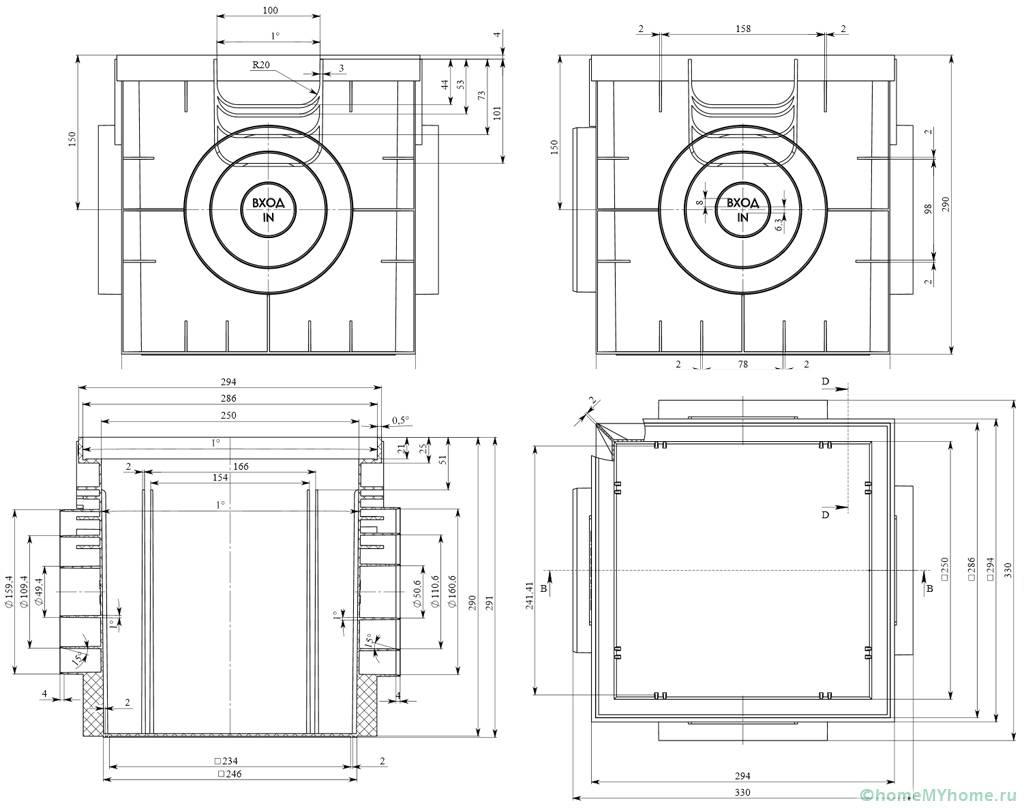

Typically, each element includes:

- volumetric housing for receiving moisture;

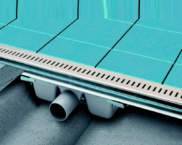

- external grille for decorative and protective functions;

- siphon for further drainage of liquid.

Note! The outer grille is an integral part, which can be subject to different loads, therefore it should be selected taking into account the operating conditions in a particular case.

About each material of manufacture separately

The technical characteristics of different materials cannot completely coincide, therefore the advantages and disadvantages of the finished products are completely different. Most of the elements are made from cast iron, concrete or plastic. All of them are capable of withstanding different loads.

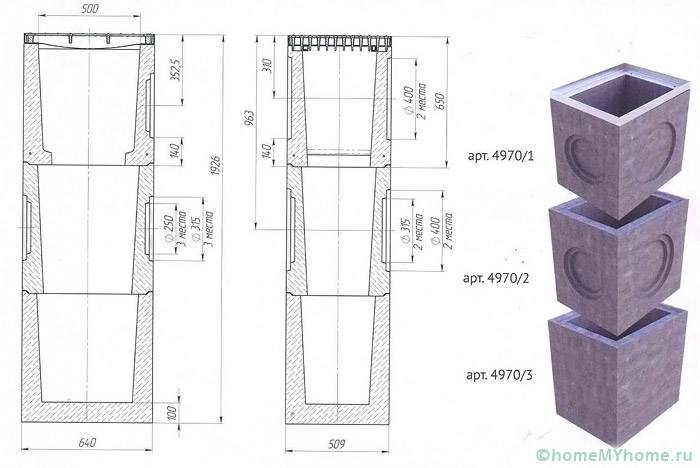

Concrete structures

Almost every developer has the opportunity to buy a storm water inlet made of concrete. There are a great many options for the execution of such structures. Some owners of suburban areas make them themselves.

Concrete products are resistant to moisture, so they are ideal for collecting precipitation. They can be successfully operated for tens of years under high load. They should be selected if heavy equipment will regularly move around the site.

Cast iron products

Most cast iron models are used in road construction to drain rainfall from roadways and sidewalks. Storm inlets db2, which are widely used, are excellent for these purposes. In individual construction, less massive structures are used.

In suburban areas, models are usually installed, the width of which is 470 mm and the length is 695 mm. Products are characterized by a high level of wear resistance, and therefore attract many developers.Cast iron grids of storm water inlets are simply inserted into the inner part of the block without additional fasteners.

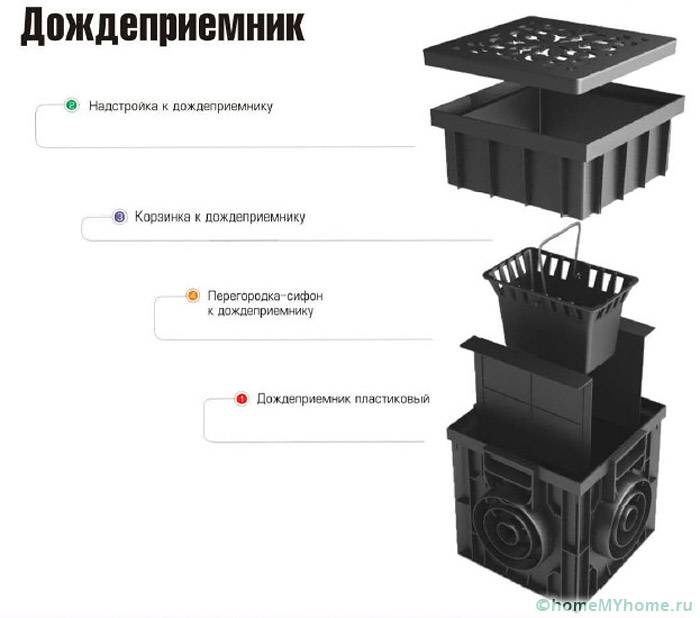

Plastic elements

The most widespread in the current conditions are plastic products. They allow not only to receive sediments, but can also be used as revision wells, since they can be placed on top of each other.

The advantages of plastic storm water inlets are as follows:

- light weight greatly simplifies the installation of elements and transportation to the future installation site;

- plastic is a durable and weather-resistant material, so products made from it serve for a long time;

- thanks to smooth surfaces, the process of cleaning structures is not difficult;

- storm sewer pipelines can be installed without the use of additional fasteners;

- the installation of the elements is relatively simple, therefore, when doing the work on your own, problems usually do not arise.

Note! When sizing plastic storm water inlets, the amount of wastewater entering the system per day should be taken into account. The higher this indicator, the more spacious the storm water inlet should be.

Self-contained water collection point

Of course, you can buy a plastic storm water inlet, which is easy to install. However, you can make a reliable concrete structure with your own hands without spending a lot of money. Below is a sequence of basic steps.

- Before carrying out installation work, marking is done. After that, a pit 30 cm wide is pulled out than the storm inlet itself. And 15 cm more than its depth.

- The bottom of the pit is covered with a mixture of sand and cement. After careful compaction, its thickness should be 10 cm.

- A waterproof membrane made of glassine or polyethylene film is spread from below so that water does not escape from the concrete composition.

- For side surfaces, formwork from a board or plywood... Discharge pipelines are immediately built into it.

- The bottom and sides are filled with concrete mix B25 or higher. The height of the structure must match the level of the asphalt, tiles or any other coating that is used to create the track.

- After 2-3 days, the formwork is disassembled, however, the concrete will gain final strength only after 28 days.

- A basket is inserted inside the structure to collect various garbage (leaves, branches, stones, and so on). A lattice made of suitable material is installed on top.

Note! After installing the storm water inlet, it is imperative to seal the technological seam directly between the structure itself and the track coating.

Calculator for calculating the volume of storm water

The cost of plastic storm water inlets for storm sewers

Since storm water inlets made of plastic are easy to install and operate, it is suggested that you familiarize yourself with their cost, especially since their prices are not too high. The table offers to consider the models of the most popular brands.

Table 1 . Average cost of plastic storm water inlets

| Picture | Manufacturer | Dimensions in millimeters | Price in rubles |

|---|---|---|---|

| Gidrolica | 300x300 | 490 |

| 400x400 | 1 340 | ||

| Europlast | 200x200 | 520 |

| 300x300 | 910 | ||

| 400x400 | 2 106 |

Helpful information! As you can see, the prices of plastic storm water inlets are not high. However, the table mentioned the cost of products without additional elements (waste baskets, grates, and others).

Learn more about storm sewers

The main work on the construction of a drainage network for the removal of sediments from the building should begin with the creation of a project. At the preliminary stage, when performing calculations, the following points should be considered:

- the amount of precipitation typical for a particular region;

- the volume of gutters installed under the roof;

- location of pipelines of underground systems;

- drainage area.

If the above points are observed during the development of the project, then the size of storm inlets and pipelines will not be difficult to select. In addition to the listed parameters, the features of the site relief and the requirements, which are reflected in the SNiP clauses, must be taken into account.

Summarizing

When draining the soil in front of the house, it is quite difficult to do without storm water inlets for storm sewers. To drain precipitation from the roof of the building, they are positioned so that the outlet of the drainpipe is located strictly in the center of the tank. Then all the water that will drain from the roofing will end up at the collection point and enter the sewer system.

Video: installation of a storm water drainage system